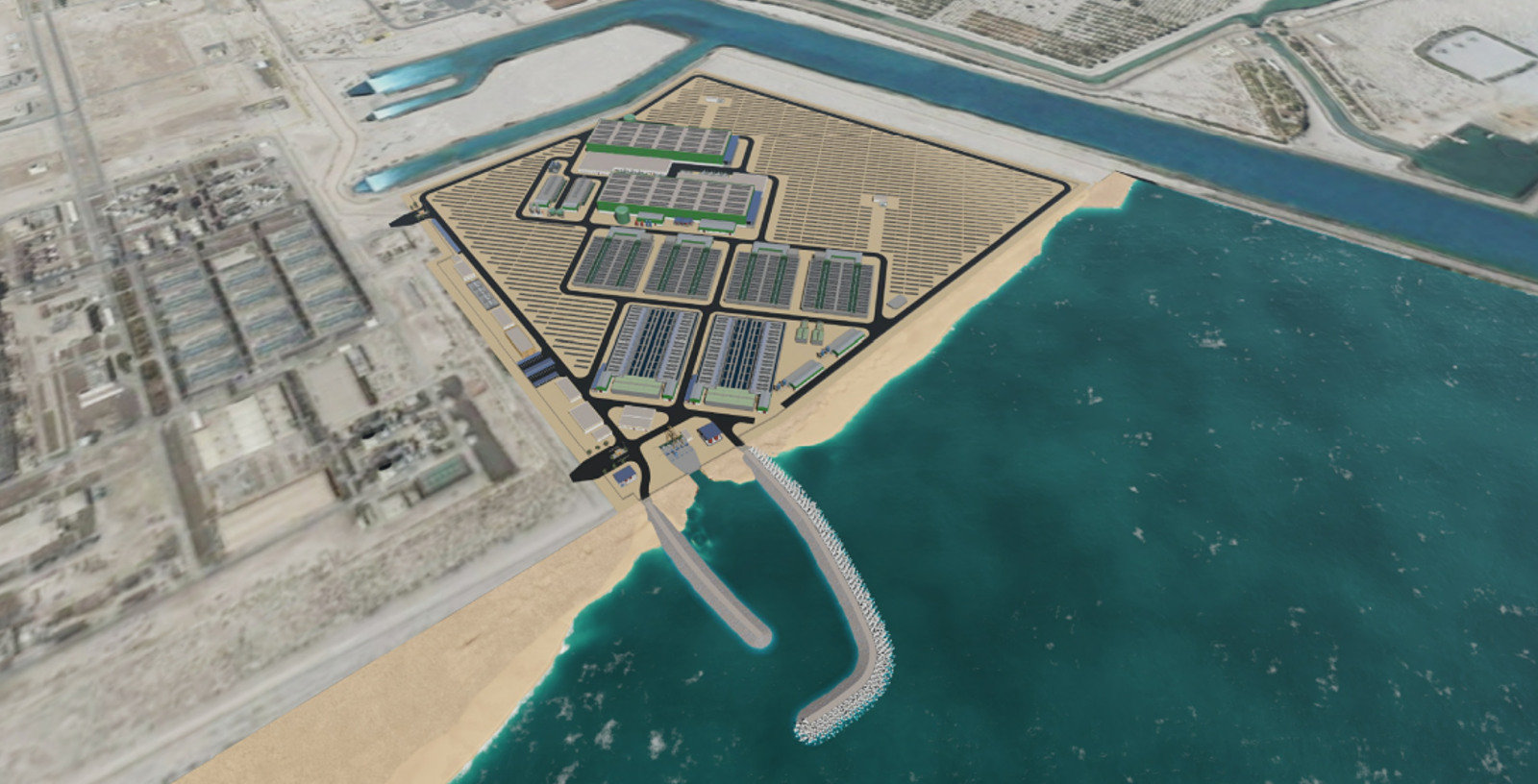

- Location: Abu Dhabi (United Arab Emirates)

- Capacity: 909.000 m2/day

- Technology: Reverse osmosis desalination

- Population served: 4.500.000 people

This project is a landmark in the sector and without doubt the most important engineering project for this type of infrastructure. And SAVENER has contributed its expertise and skills in the jobs and areas where it has been requested by the international consortium that leads the design of this landmark in desalination plants.

It is the largest reverse osmosis desalination plant in the world, and it is located in the energy and water generation complex at Taweelah.

With a production capacity of 909,000 m3/day, the Taweelah desalination plant can guarantee the water supply for the city of Abu Dhabi for one year and is the first large-scale desalination plant in the country to combine the production of drinking water with the generation of clean energy, thanks to the installation of a photovoltaic solar array to produce 40 MWp of power.

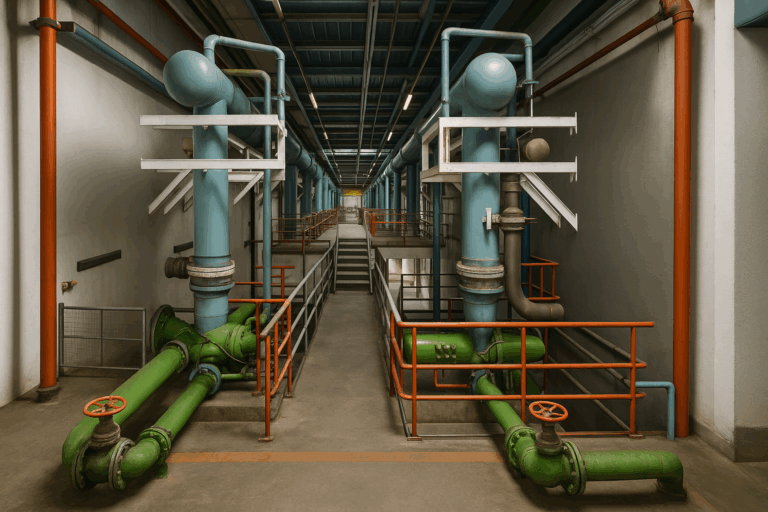

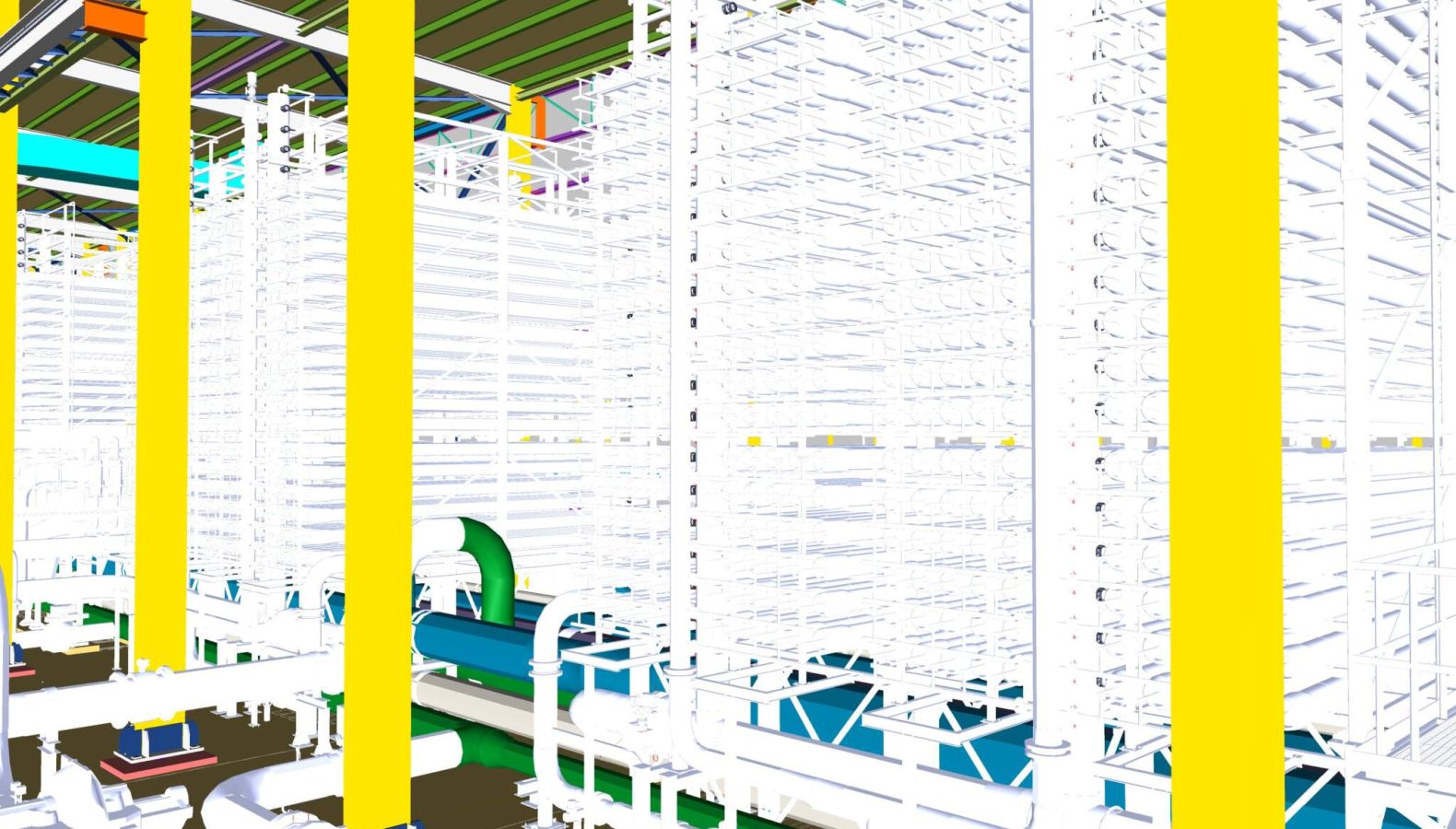

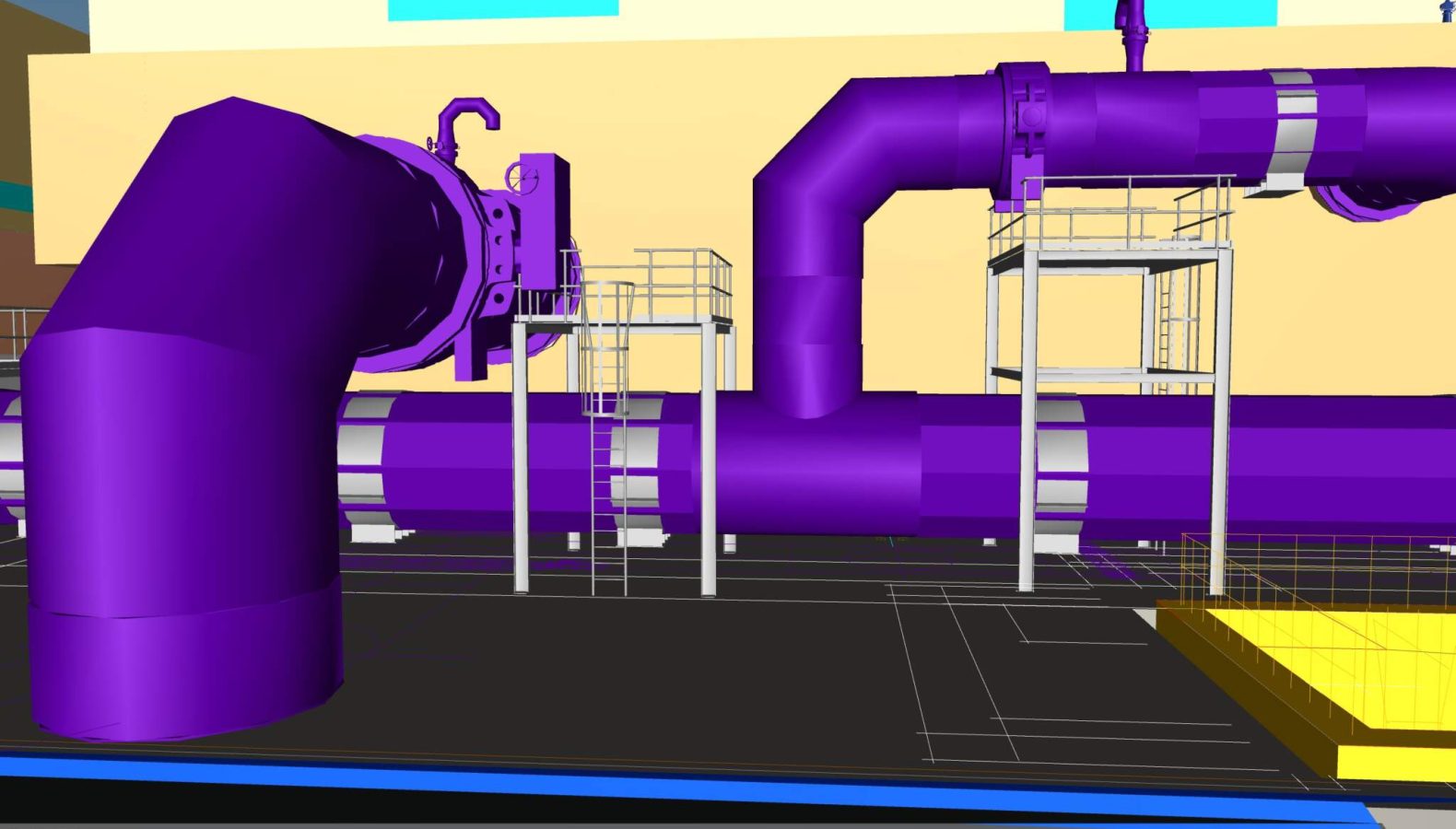

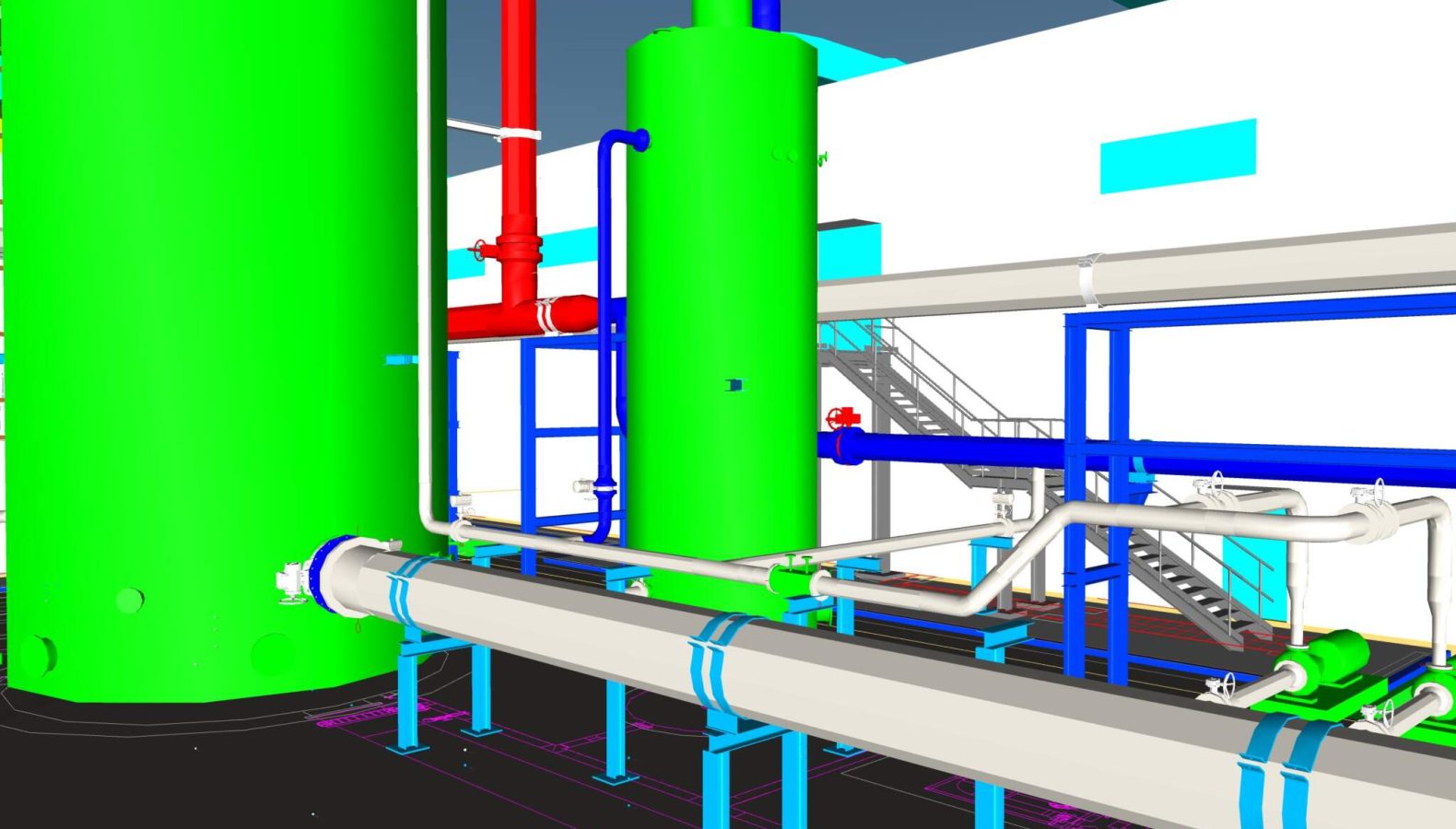

The Design (3D Modelling), Electricity and Instrumentation and Control Departments have taken part in the development, design and modelling of different parts of the complex. For example, the I&C Department designed, calculated, modelled and implemented different elements and jobs ranging from the lists of field elements to the development of Technical Specifications, including the creation of data sheets, measurements (BoQ) and the layout of elements such as signals, solenoid valves, pneumatic consumers, junction boxes, switches, etc.

After many years working on this type of project, often in collaboration with teams from other companies, SAVENER’s technicians are skilled at integrating into any development team and any area to create an effective and efficient working team.

Savener’s expertise in this type of project, its flexibility in adapting to the company’s EPC processes and harmonization with the rest of the technical crew, meant that these works could be carried out smoothly, with high quality in the results and optimizing the expansion of the project with speed and precision.