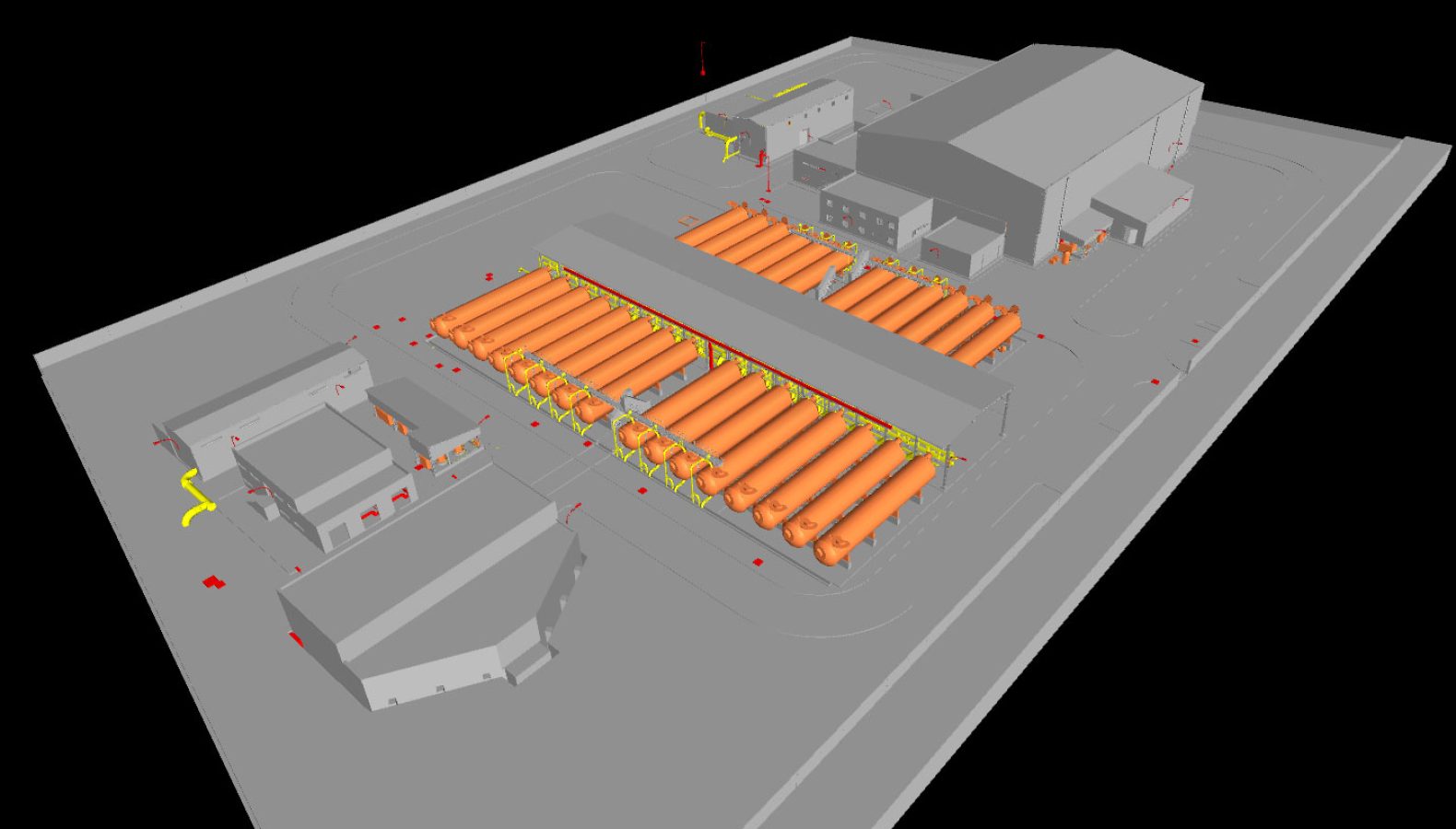

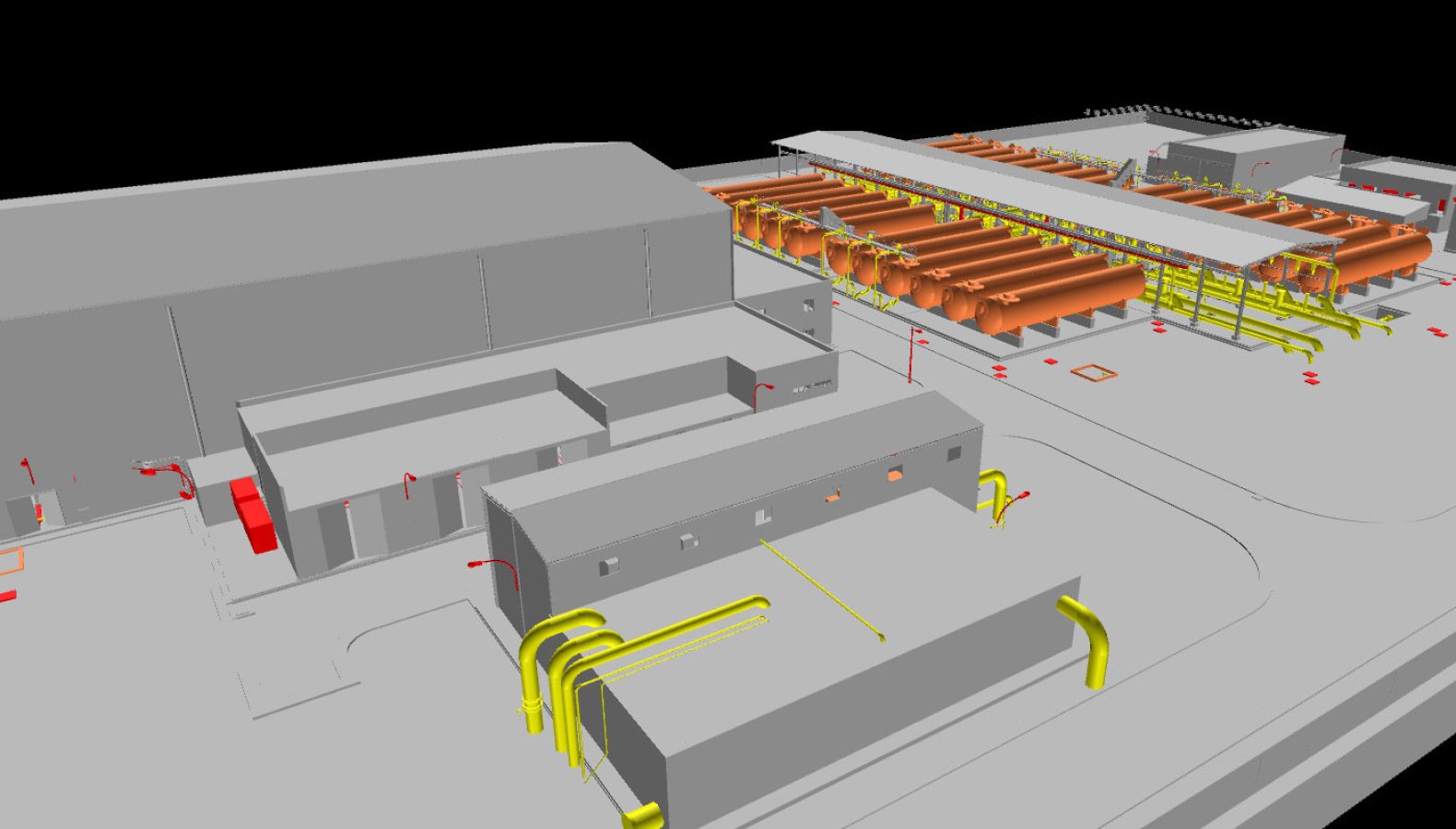

- Location: Sousse (Tunisia)

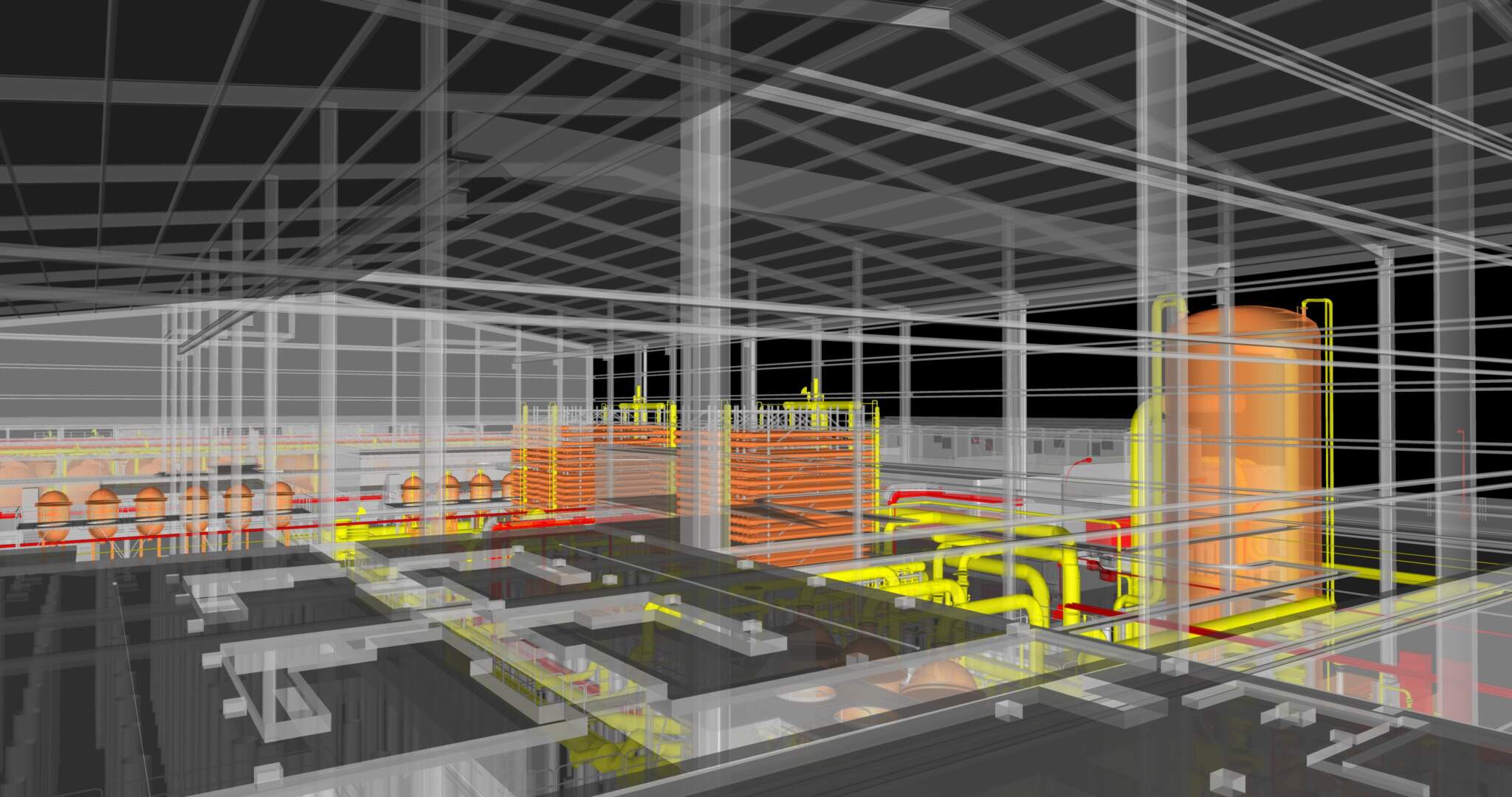

- Capacity: 50,000 m3/day being the civil works prepared for a future expansion to 100,000 m3day

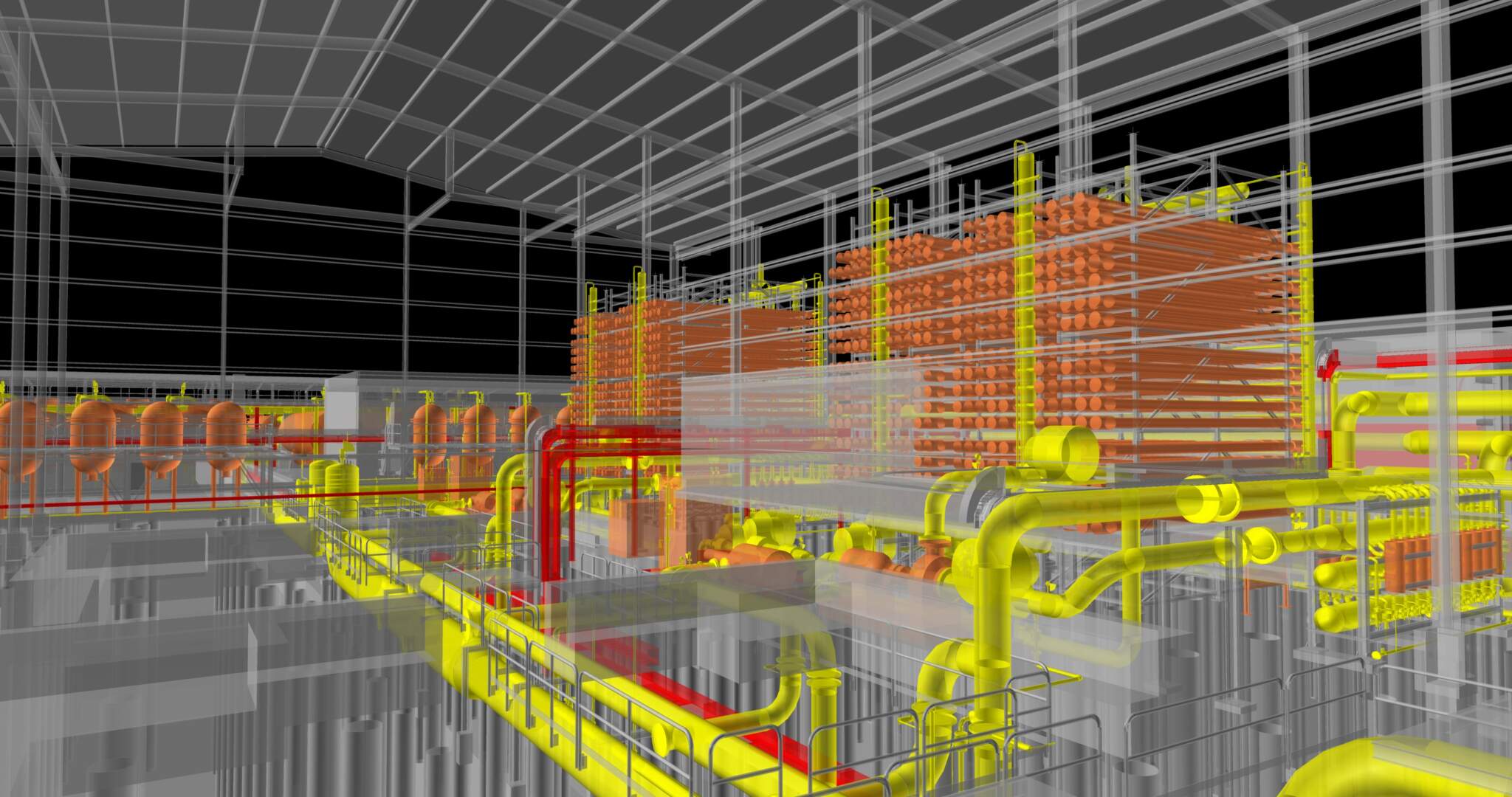

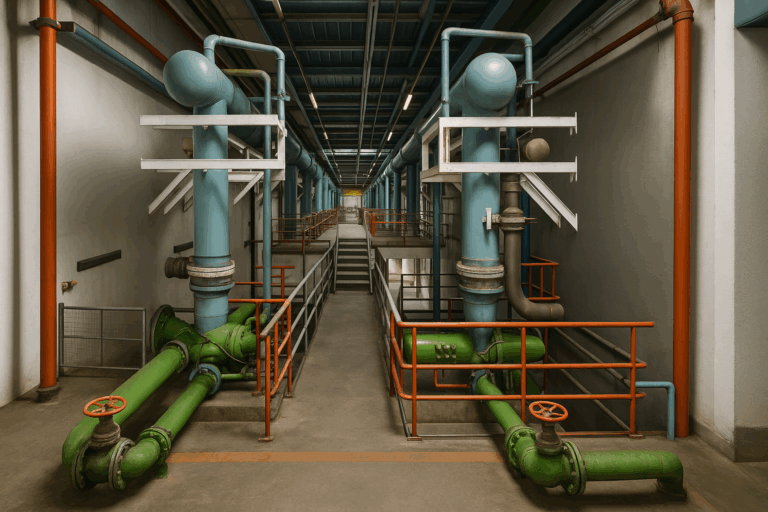

- Technology: Reverse osmosis

- Client: National Water Management and Distribution Company (Sonede)

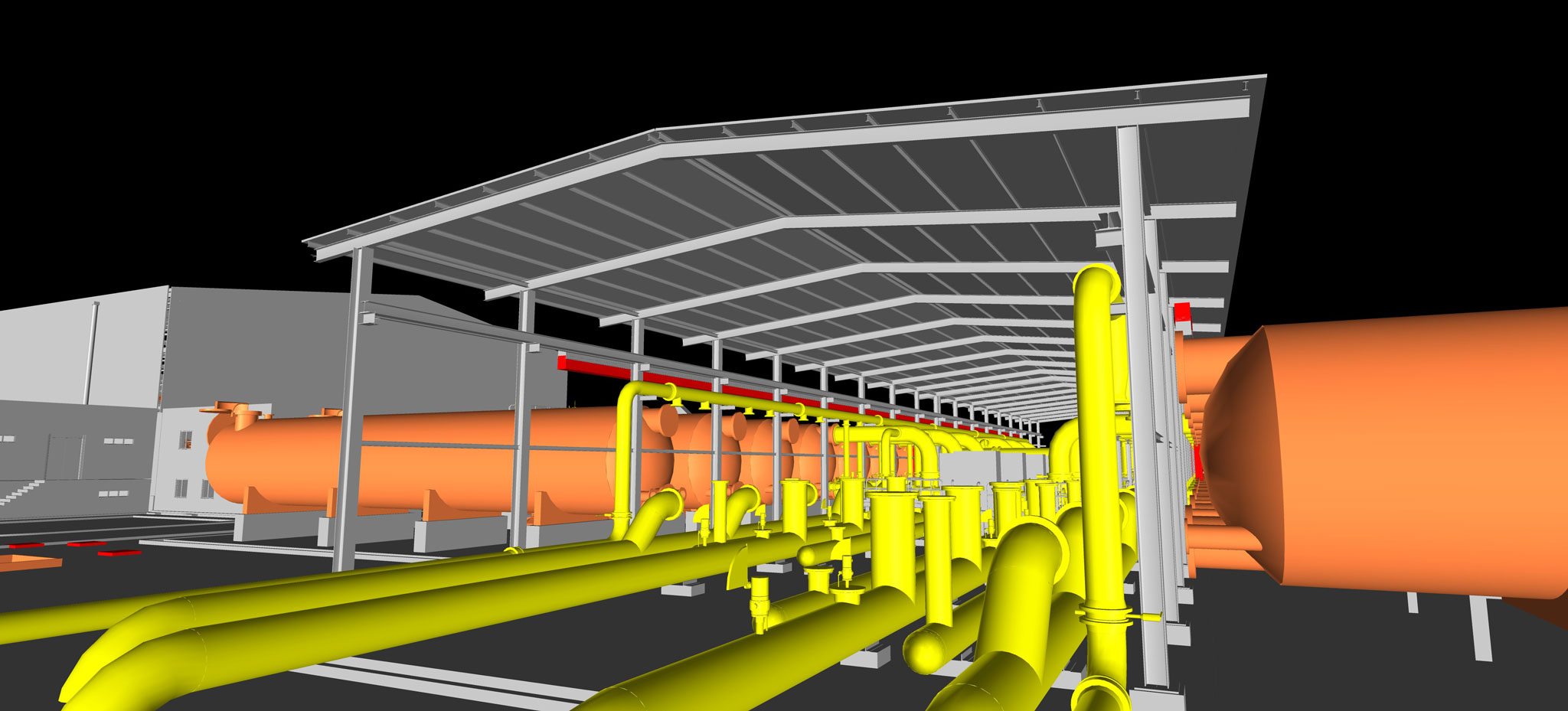

The purpose of this project is to produce drinking water from sea water taken from the canal of cooling water for the Sidi Abdelhamid power station in Sousse, owned by the Tunisian Company of Oil and Gas (STEG). This desalination plant will be able to produce 50,000 m3/day. The water is subjected to a process of pre-treatment with two filter stages and two reverse osmosis units, each producing 25,000 m3 per day

The project forms part of the package of actions implemented by the Tunisian government to promote and develop non-conventional water resources, such as desalination. Its objective is to solve the problem of water scarcity and improve water quality, and to supply the growing demand from the main tourist destinations.

SAVENER was selected to prepare the different engineering packages that involve Design and Electricity. Abengoa, the company that carried out the design, construction and running of the plant in a JV with EPPM, turned once again to the expertise of SAVENER to deal with various issues, some of which can be defined as advanced studies.

The work carried out by the Electrical Department, which was in charge of most of the work requested for this Plant, deserves a special mention These ranged from the basic design of the low and high voltage installations, purchasing management and a review of the basic engineering of the low and high voltage electrical equipment, such as 11 kV transformers, 30 and 11 kV cabinets, CCM, LVS, Switchboards, Frequency Variators, UPS, etc.

In an initial phase of the project, Savener was also hired to carry out different electricity studies, such as short-circuits, current flow, selectivity and factor correction for power and lighting.

Savener’s expertise in this type of project, its flexibility in adapting to the company’s EPC processes and harmonization with the rest of the technical crew, meant that these works could be carried out smoothly, with high quality in the results and optimizing the expansion of the project with speed and precision.