- Location: Dubai, United Arab Emirates

- Capacity: 41,000 m3/day

- Technology: Reverse osmosis seawater desalination

SAVENER was selected by ABENGOA to do a large part of the engineering work for the Desalination Plant in Dubai, in the United Arab Emirates.

This plant is unusual inasmuch as, besides supplying drinking water to the local population, it also provides the water that is needed for an industrial process, with all the attendant responsibilities in terms of water quality, the amount supplied and system safety.

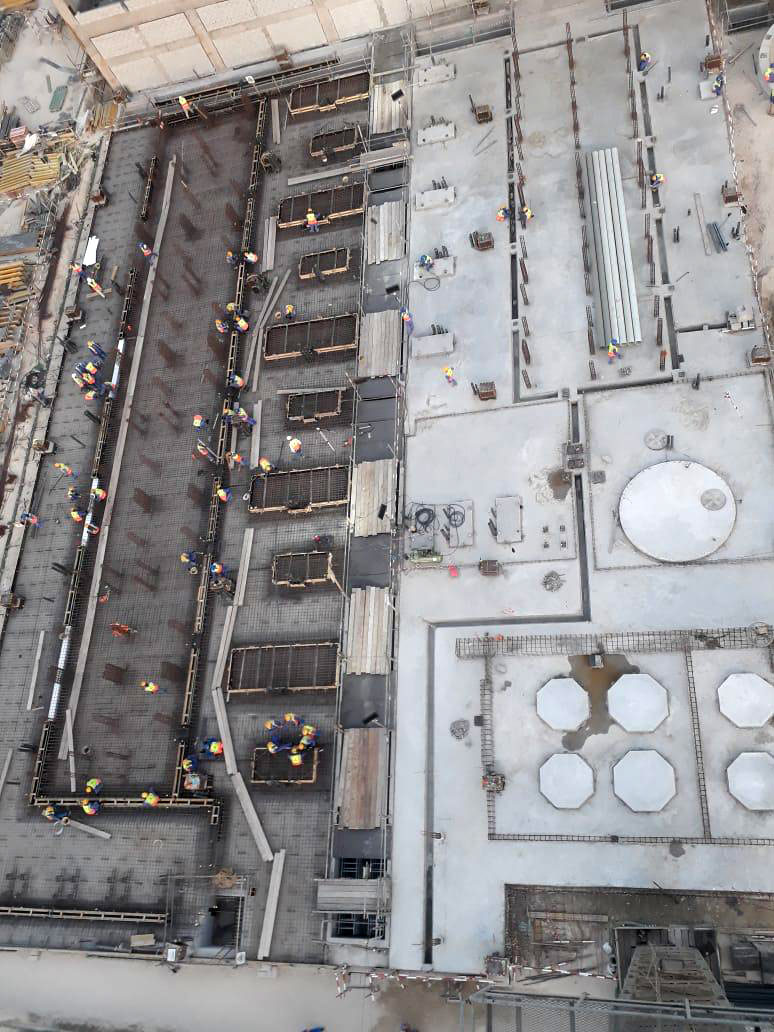

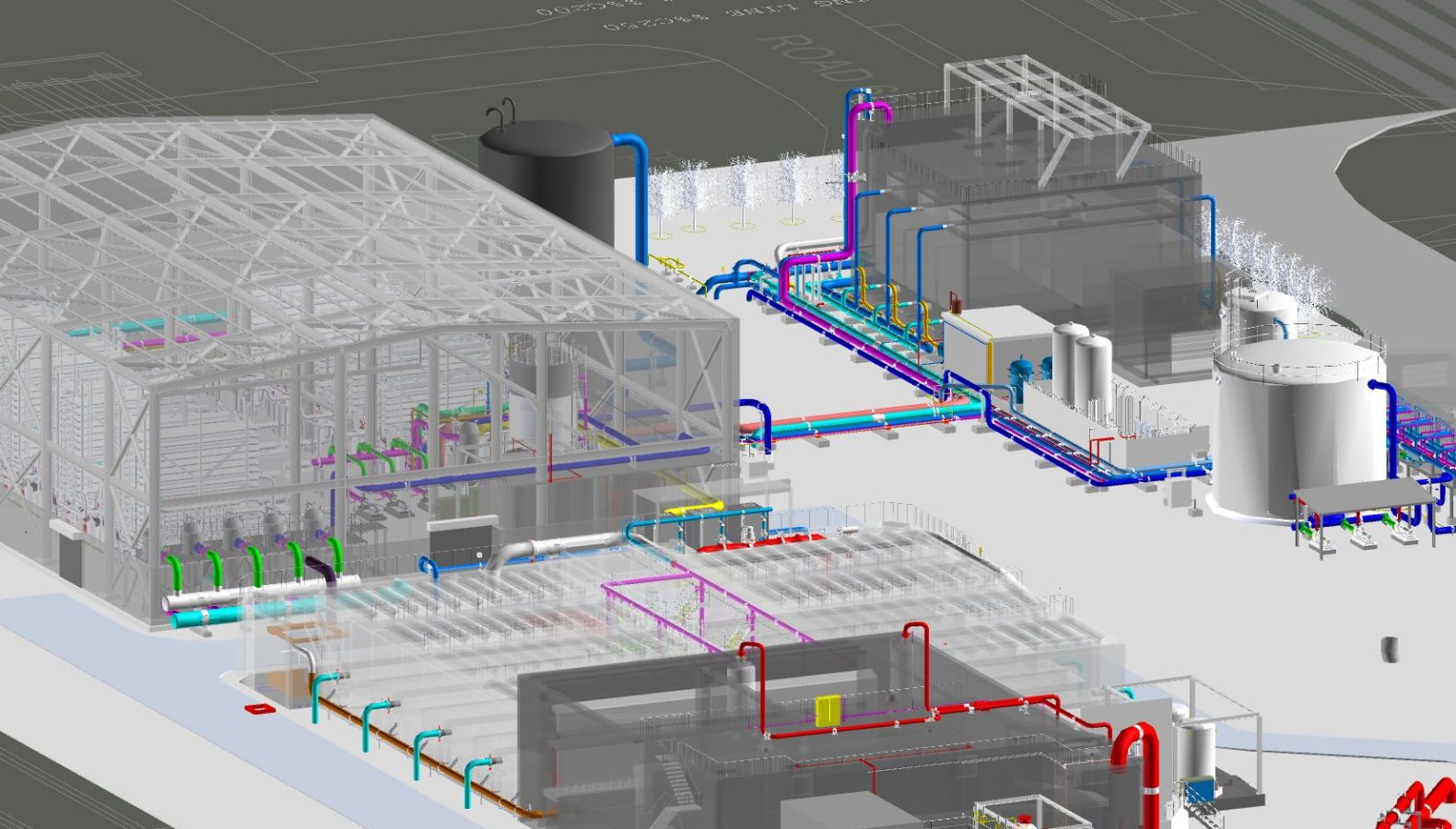

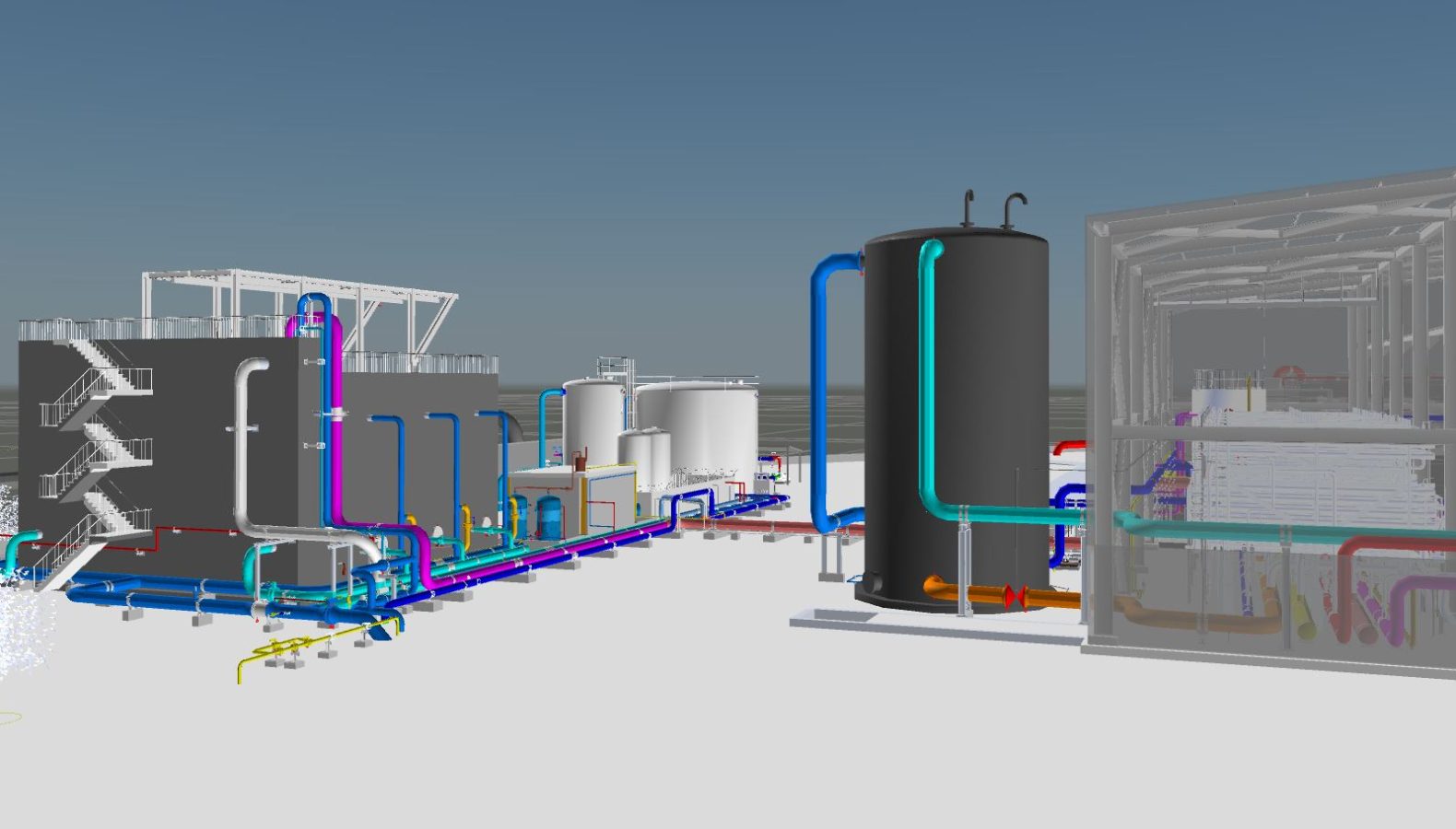

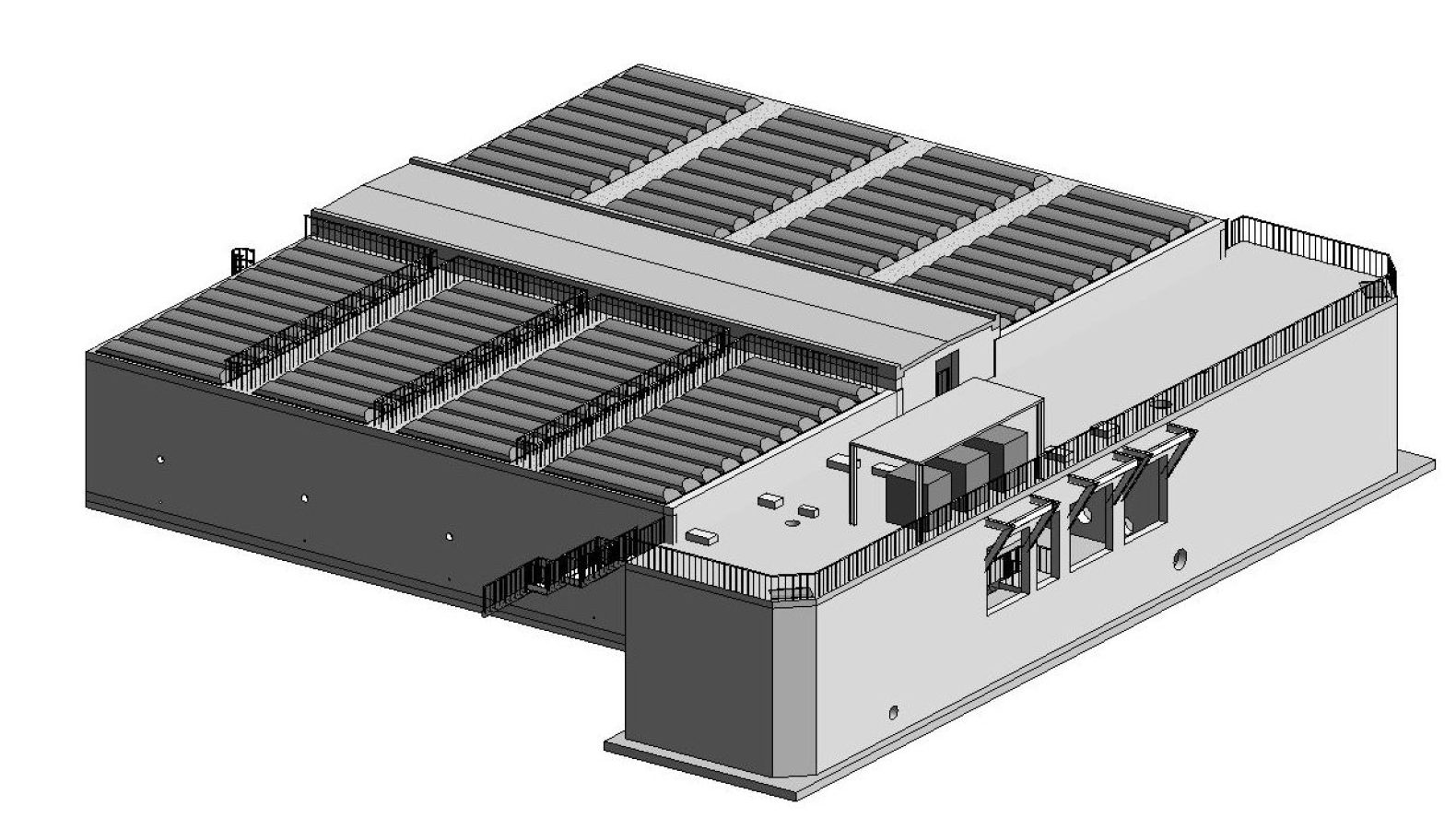

It is a sea water desalination plant that uses reverse osmosis, built within the Industrial complex of the world’s largest producer of Premium Aluminium (Emirates Global Aluminum – EGA). It has a production capacity of more than 41,000 m3/day of drinking water and water for industrial use. It has a production capacity of more than 41,000 m3/day of drinking water and water for industrial use.

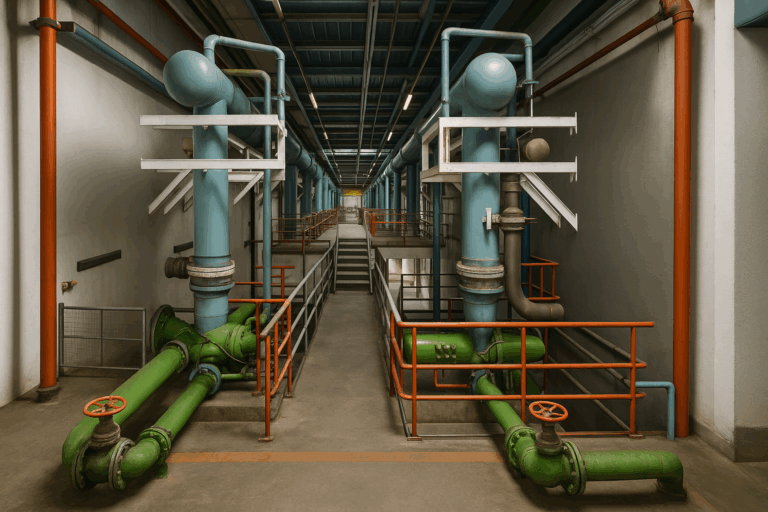

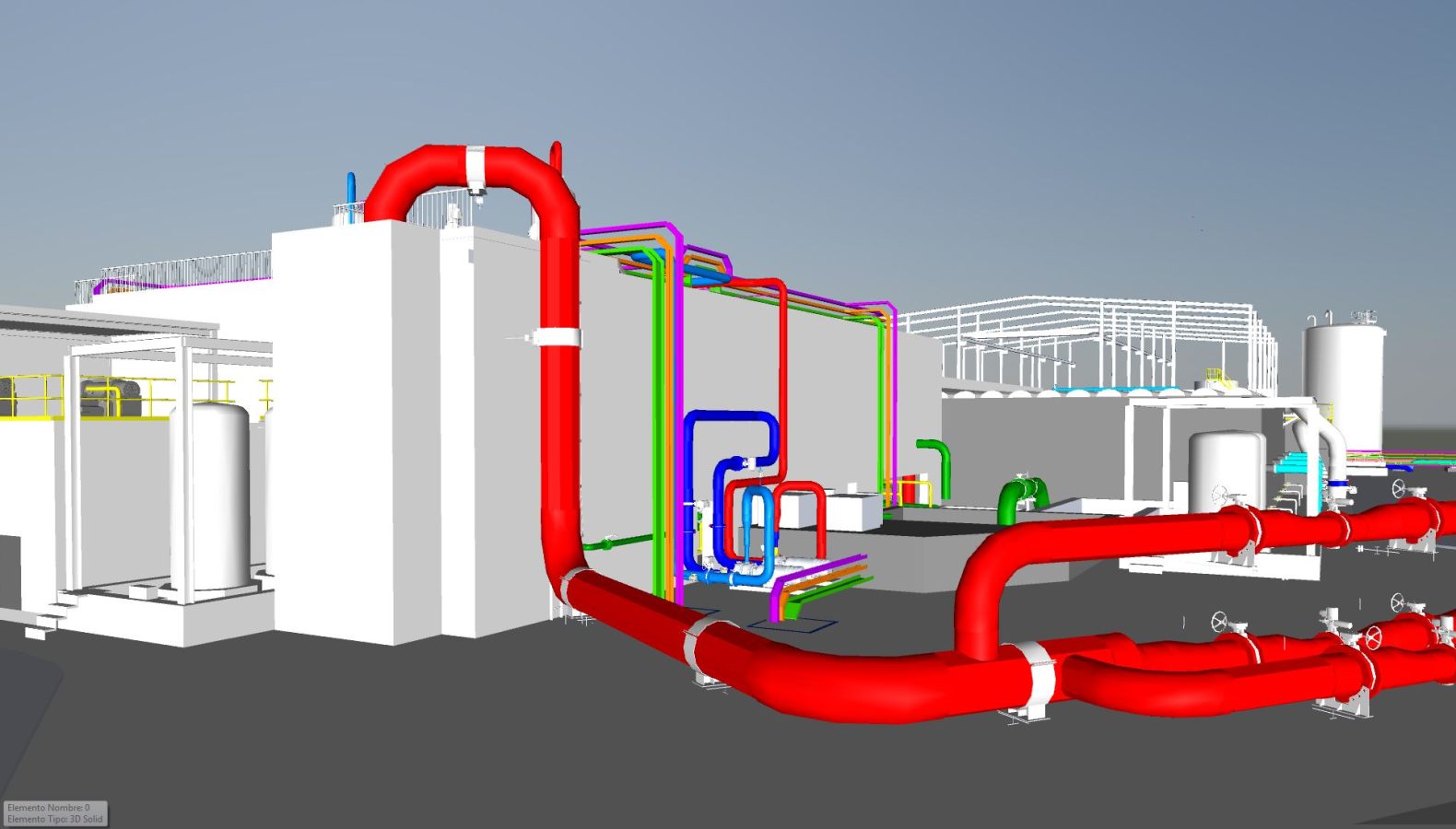

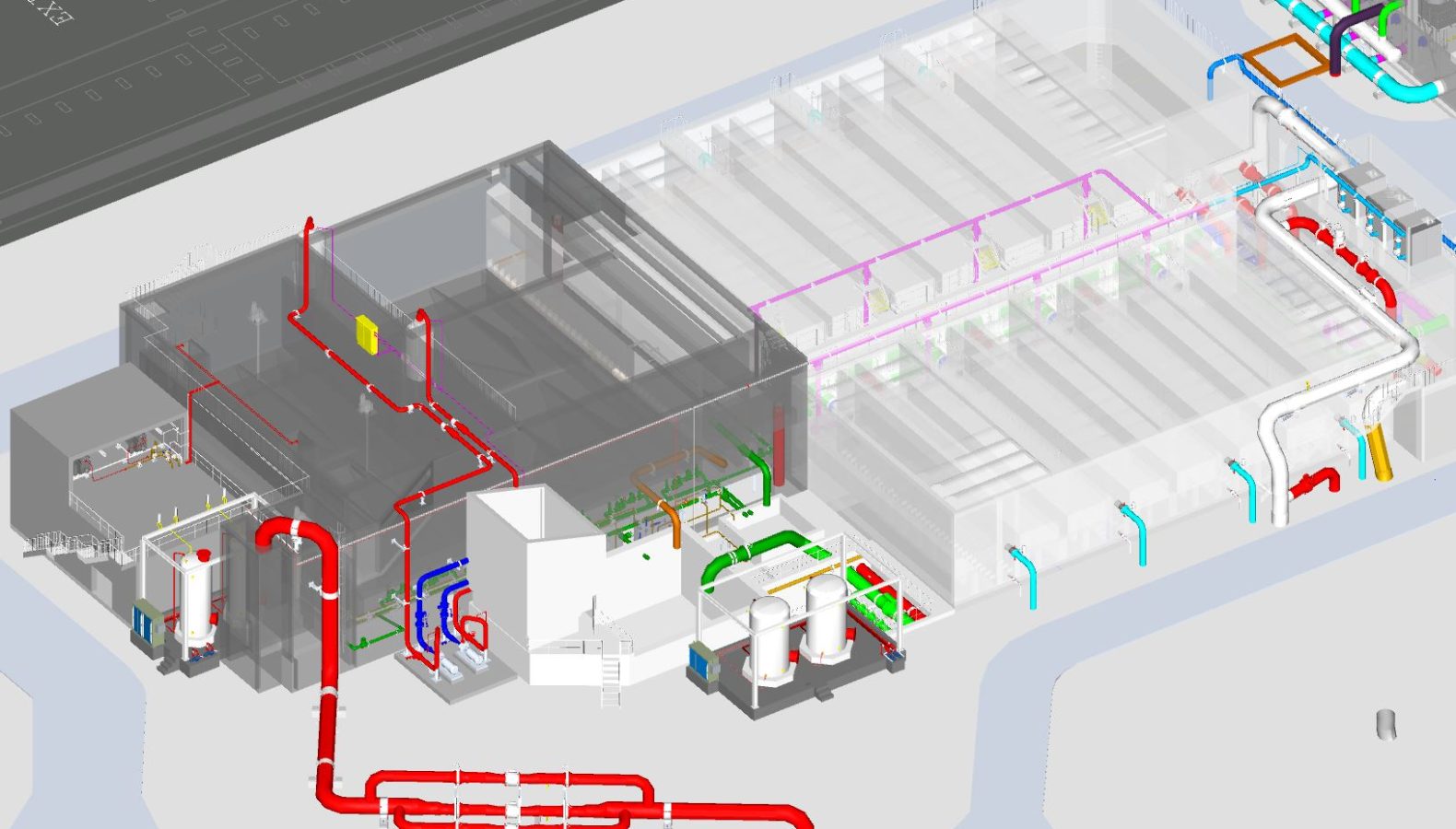

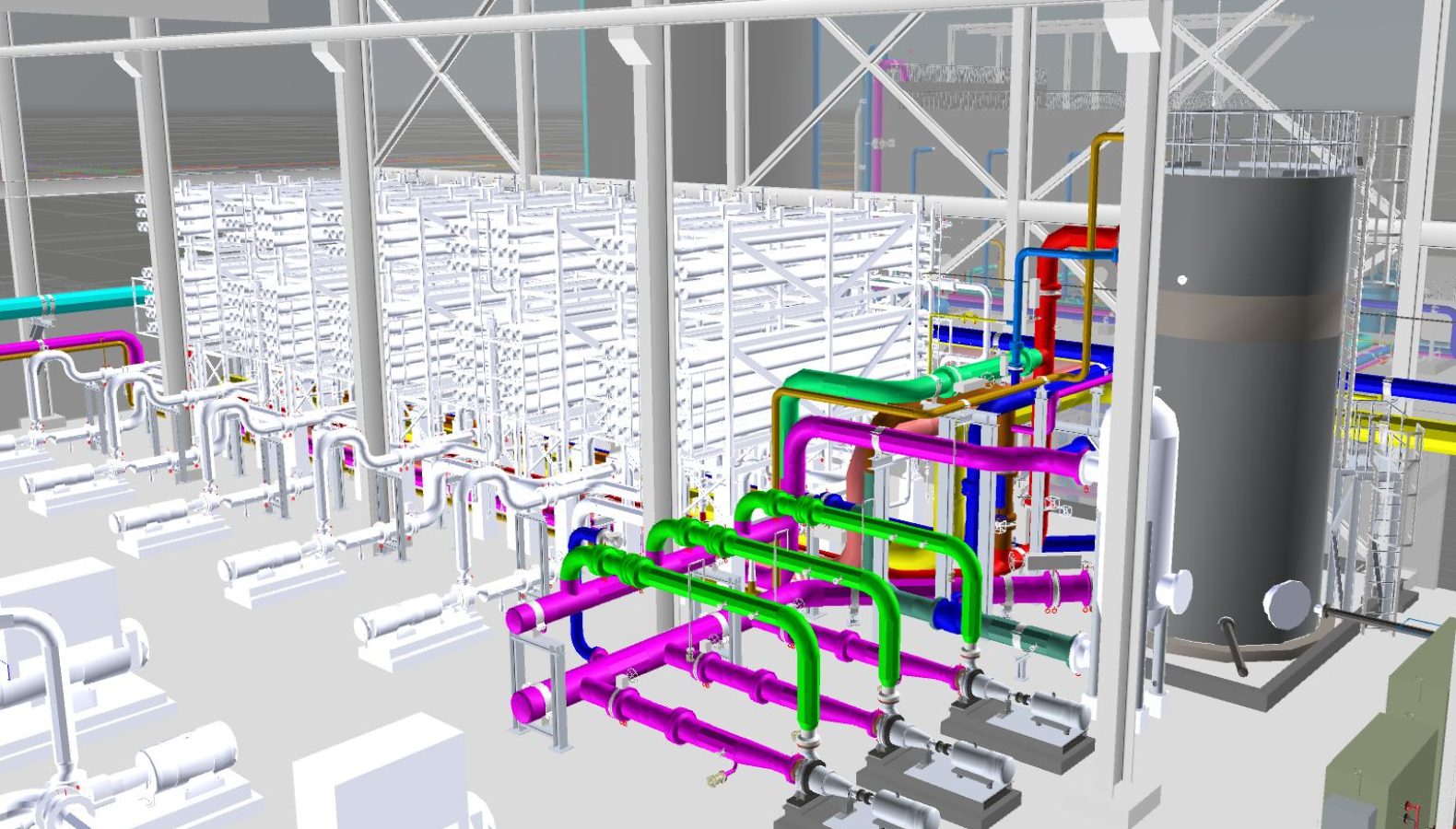

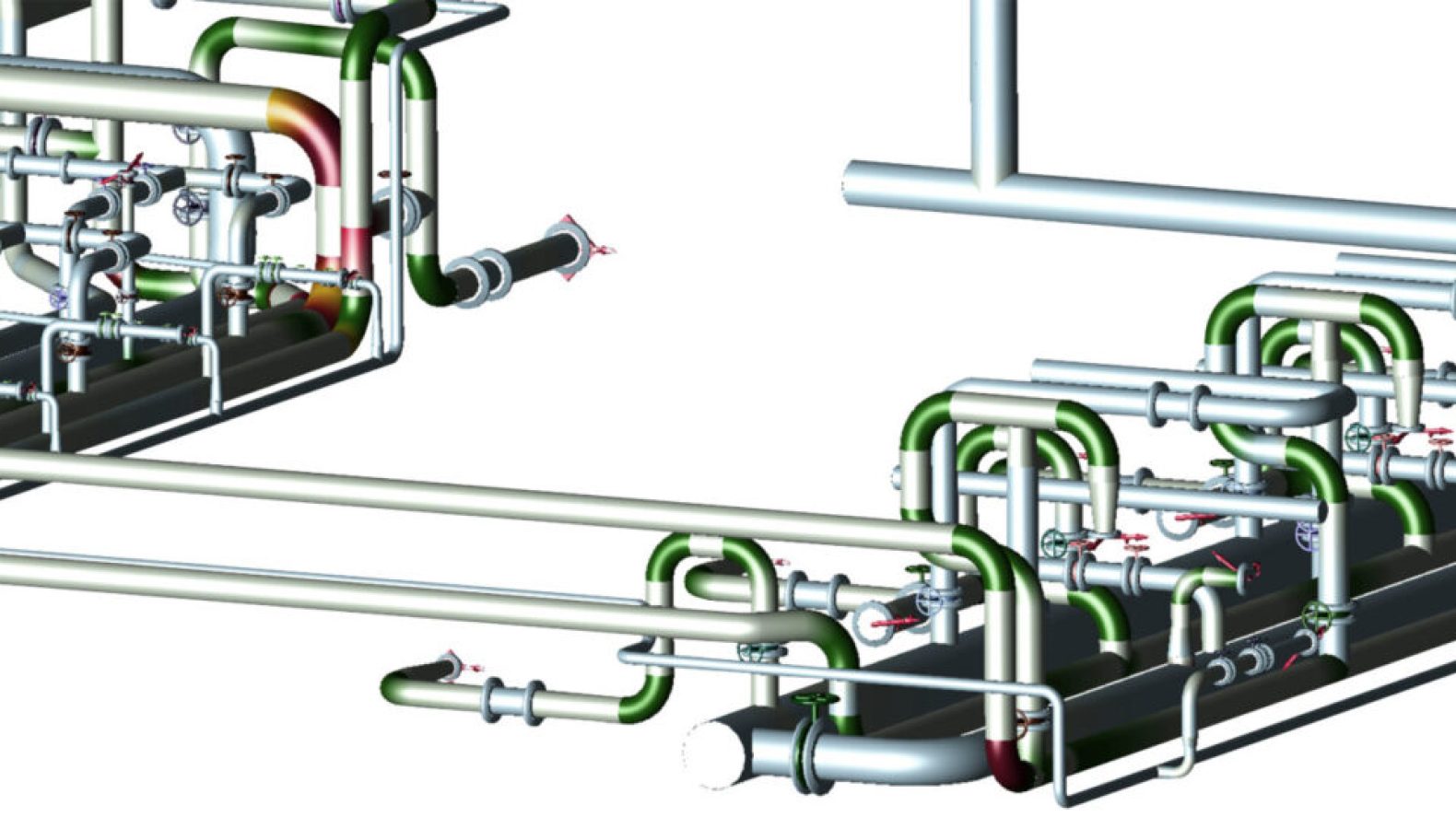

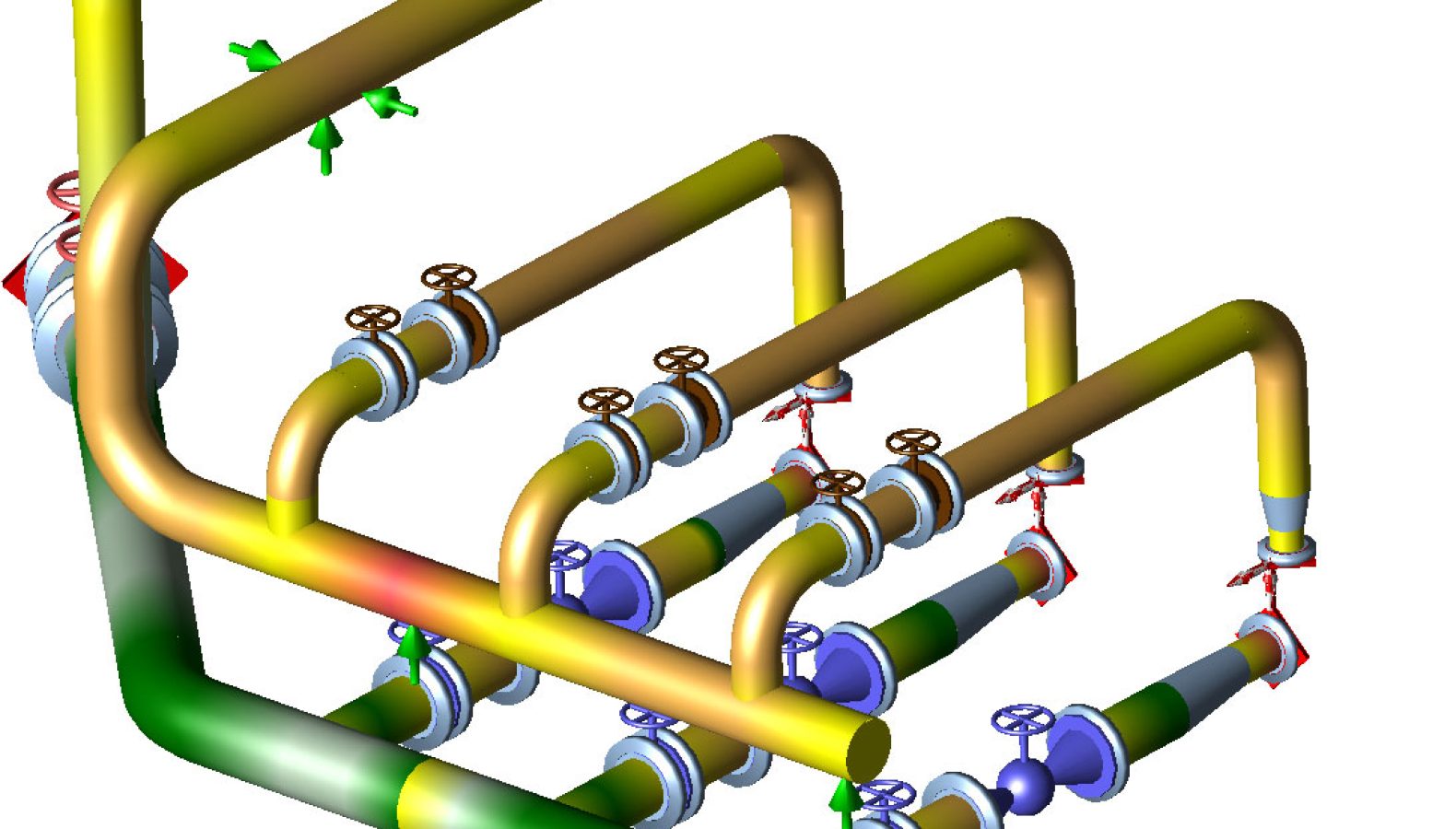

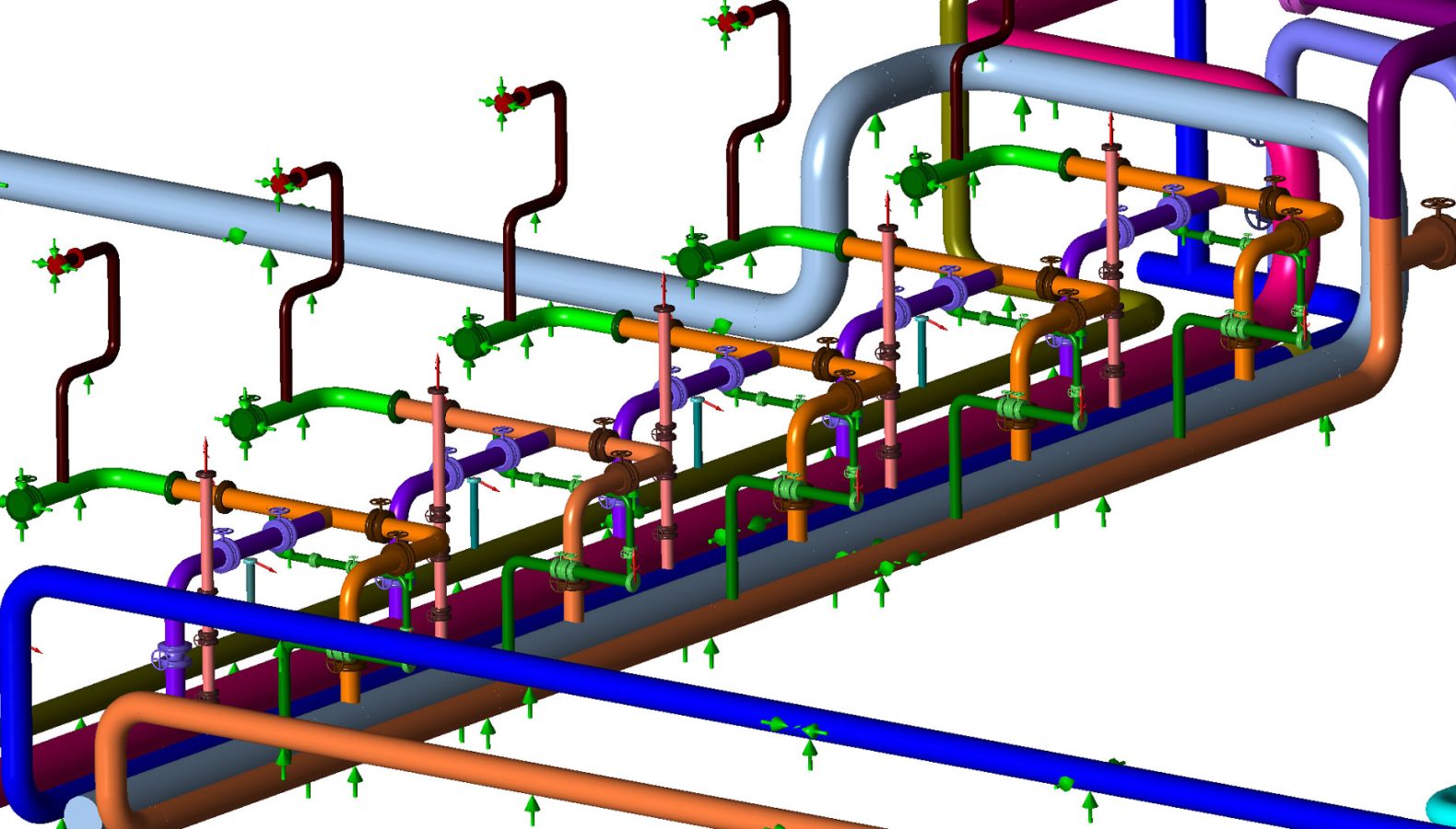

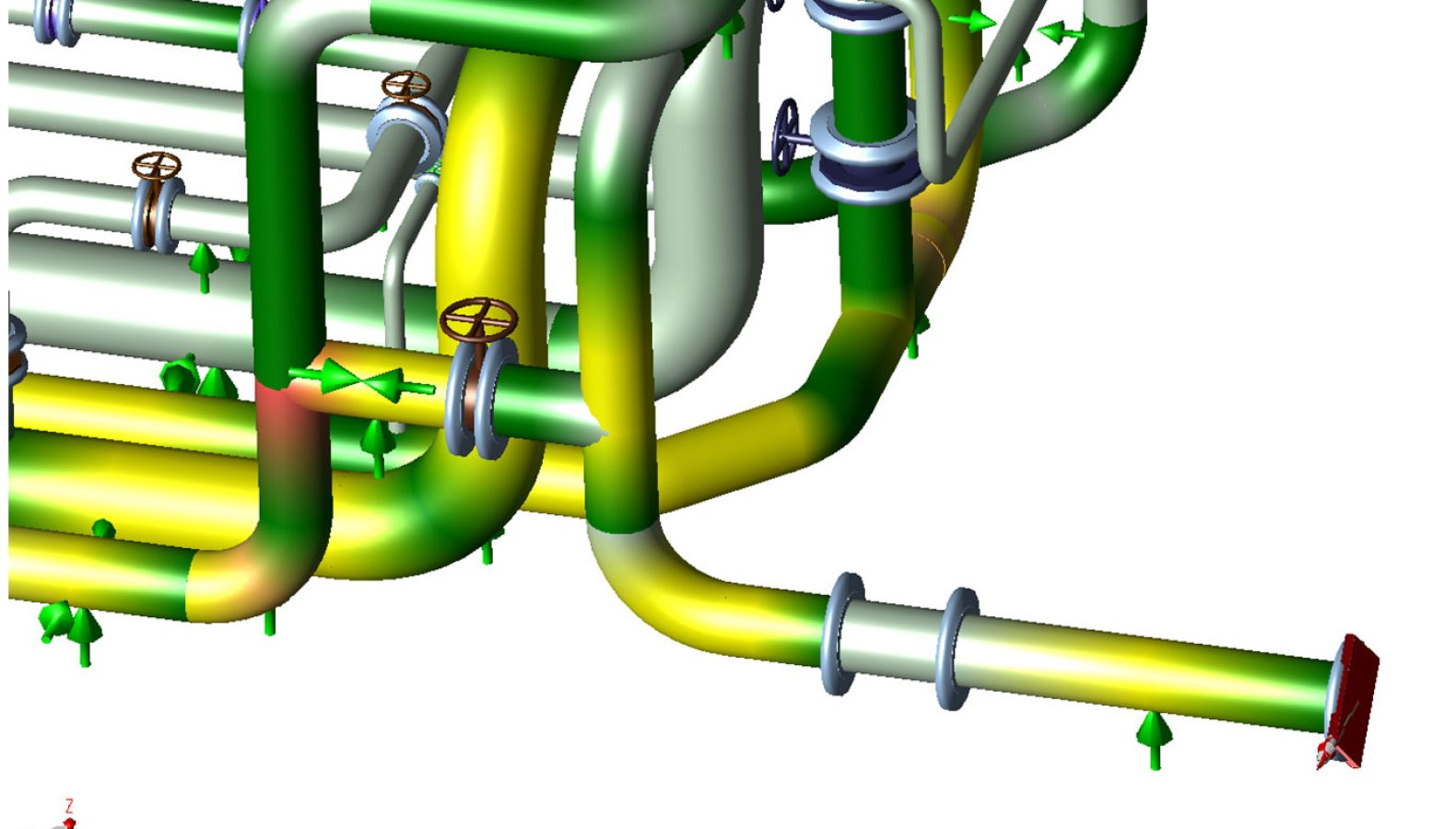

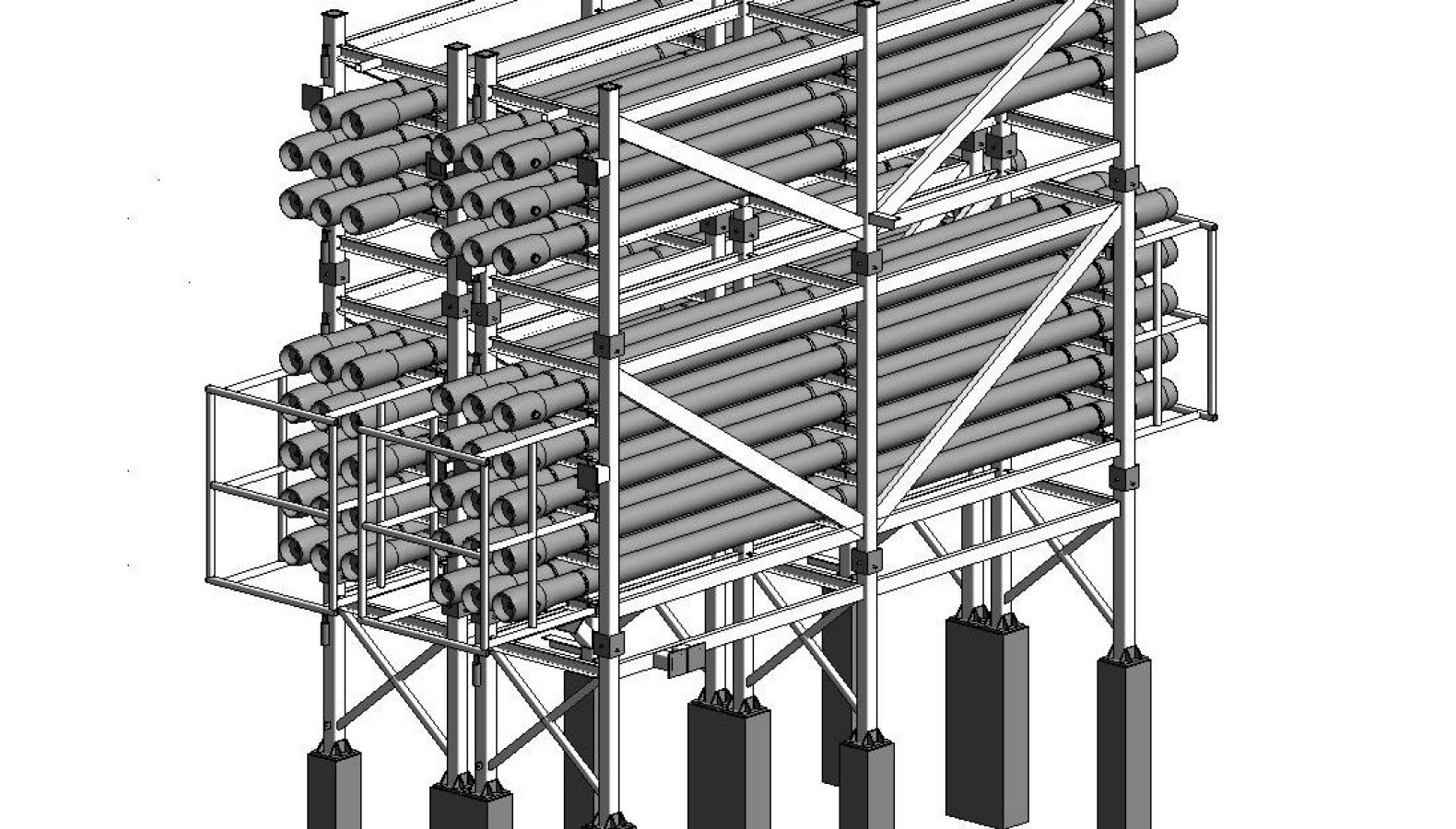

The plant includes pre-treatment through Dissolved Air Flotation (DAF) and gravity filters, a system of reverse osmosis that uses five membranes, post-treatment with calcite and carbon dioxide (CO2) beds and pumps for the water produced. It also has an electrodeionization system (CEDI) for producing pure water.

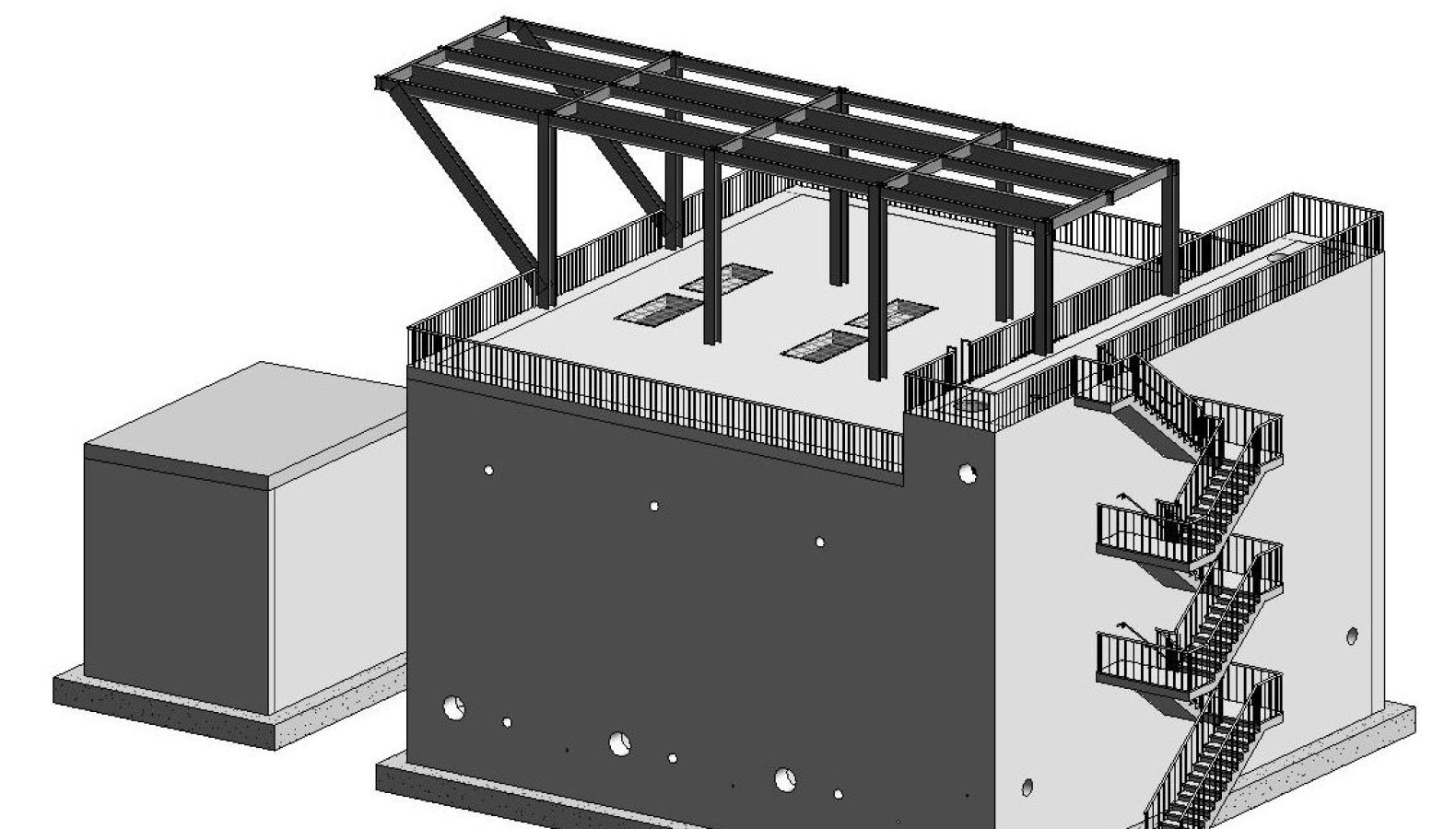

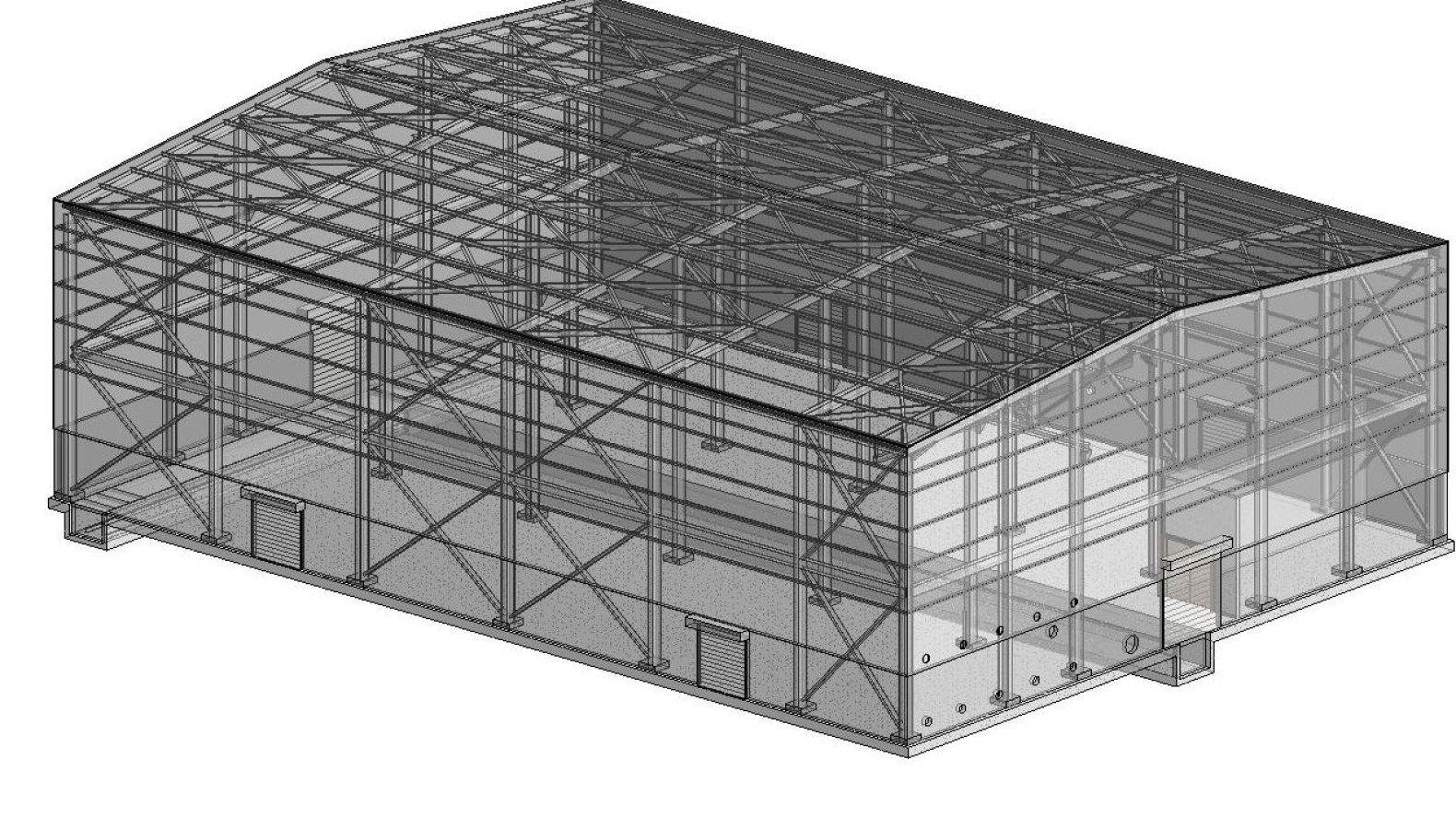

Most of SAVENER’s expertise in Desalination plants has been deployed for this project, with a first-rate team of technicians from different areastaking part, such as Design, Civil Engineering, Piping, Mechanical Engineering, Instrumentation & Control and Project Management.

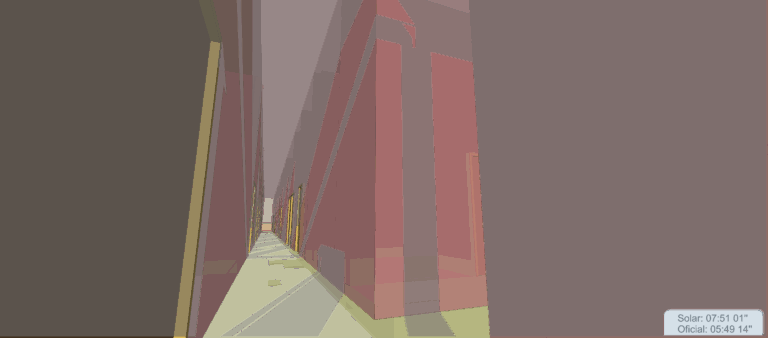

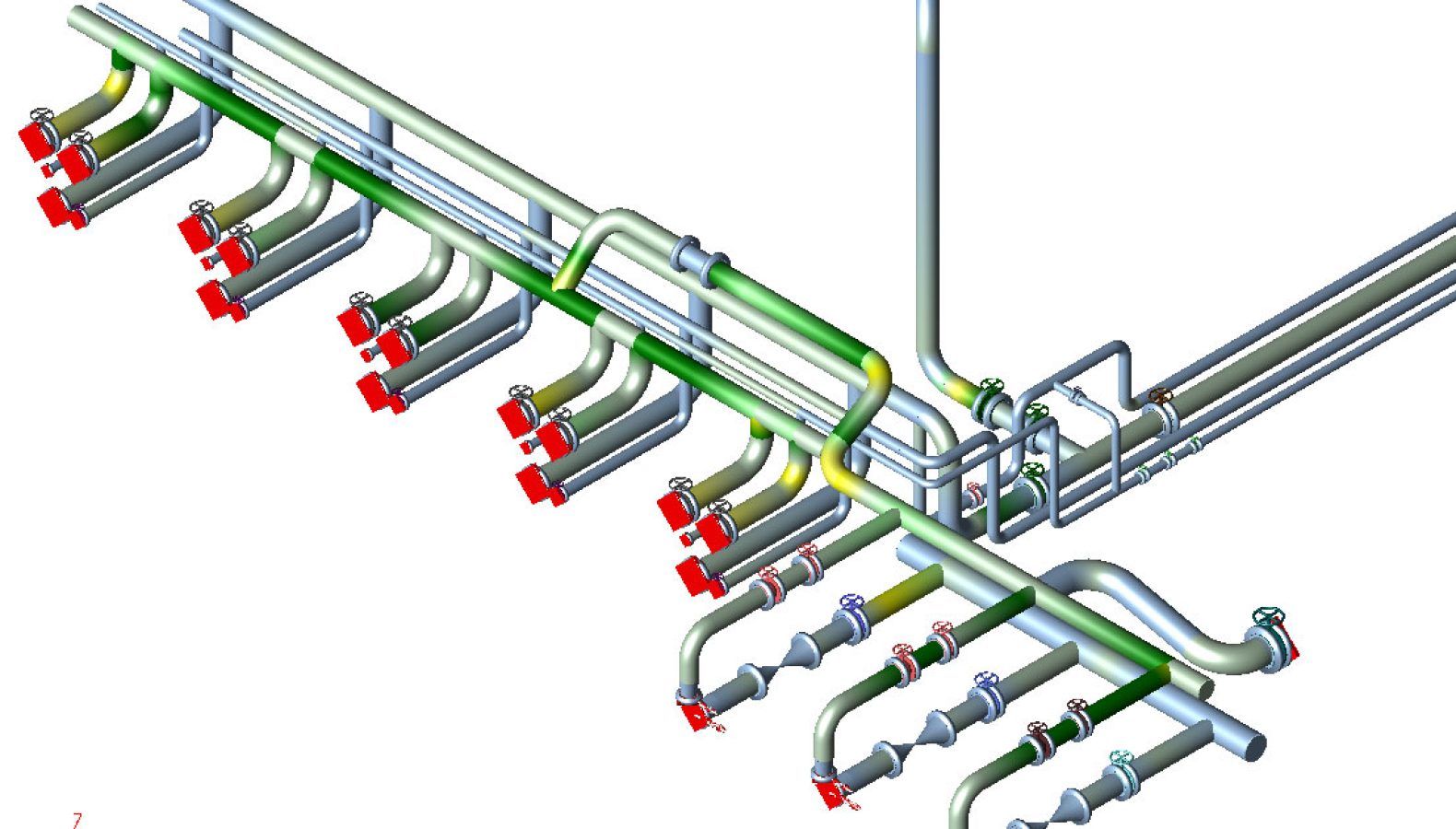

The Piping and Mechanics team did a large part of the engineering work from the calculations to the final details: stress analysis for steel and GRP, calculation and design of supports, calculations for finite elements (static, dynamic and fatigue analysis), technical tabulations, specifications, data sheets, lists of line elements and materials lists, among other duties.

The seamless integration of the SAVENER team into the workflow with technicians from Abengoa and the client has been remarkable, especially in Piping, where SAVENER has shown flexibility and agility in adapting to the necessary variations and adjustments in time and form demanded by the process manager and during implementation.