- Location: Seville (Spain)

- Main data: 3.200 m² (Surface area of works)

- Technology: Hangars, refurbishment

- Client: Airbus Defense & Space

The refurbishment of the ST35A Station was carried out to adapt it to the current needs of the plant, incorporating the pneumatic installation inside the Hangar and extending the offices.

The main objective of the action has been to update the ST35A by modifying the rails and guide plates of mobile platforms for the new performance slipway. The work included the installation of a PIT with compressed air service and electrical outlets inside the station. In addition, the corresponding civil works have been carried out for the execution of trenches on the outside for connection with the existing pneumatic installation. For this purpose, a Horizontal Directional Drilling (PHD) has been carried out under the flight line, which has allowed the runway to remain in service at all times.

The interventions were as follows: civil works, adaptation of the current offices, incorporation of a pneumatic system and installation of lighting and low voltage.

The civil works inside the hangar consisted of the incorporation of the necessary rails for the new platform in the station and the adaptation of the elevator systems with the incorporation of a pit. On the outside, the trenches necessary for the interconnection with the existing services and the replacement of the pavements to their previous state, both on the outside and inside of the Hangar, have been carried out. The Horizontal Directional Drilling has incorporated a PEHD DN250 pipe and two PEHD DN110 pipes for the crossing under the flight line of the pneumatic installation and the electrical installation.

The station’s offices have also been enlarged and a new area has been added for external personnel with the corresponding lighting, power, data and air-conditioning infrastructures, in the case of the enlargement.

In addition, a PIT has been incorporated inside the hangar for the compressed air and electrical supply services for assembly work on the aircraft, in accordance with the company’s demanding standards.

Finally, the station has been equipped with a new electrical connection to adapt it completely to its new needs. Specifically, a new secondary switchboard (P=235 kW) was installed to supply the office switchboards, socket monoliths and pentapod switchboard.

The lighting of the new area and the enlarged office area has also been calculated using calculation programmes with three-dimensional simulation that offer more precise and easily interpretable results.

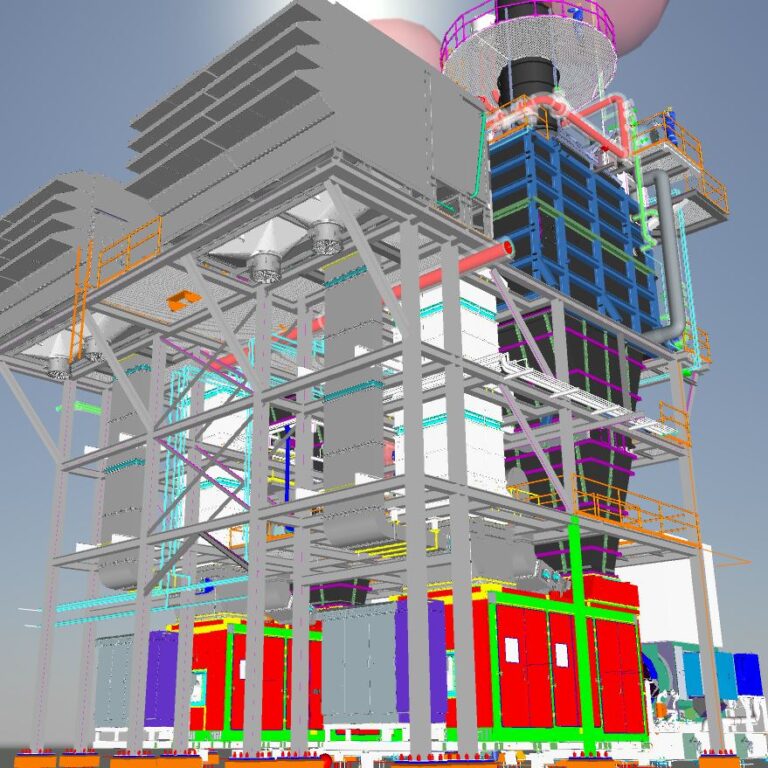

For the development of the engineering, a three-dimensional model of the station has been generated, as in all the works carried out by Savener, thus achieving an optimum level of quality and a result of implementation in the execution faithful to the project.