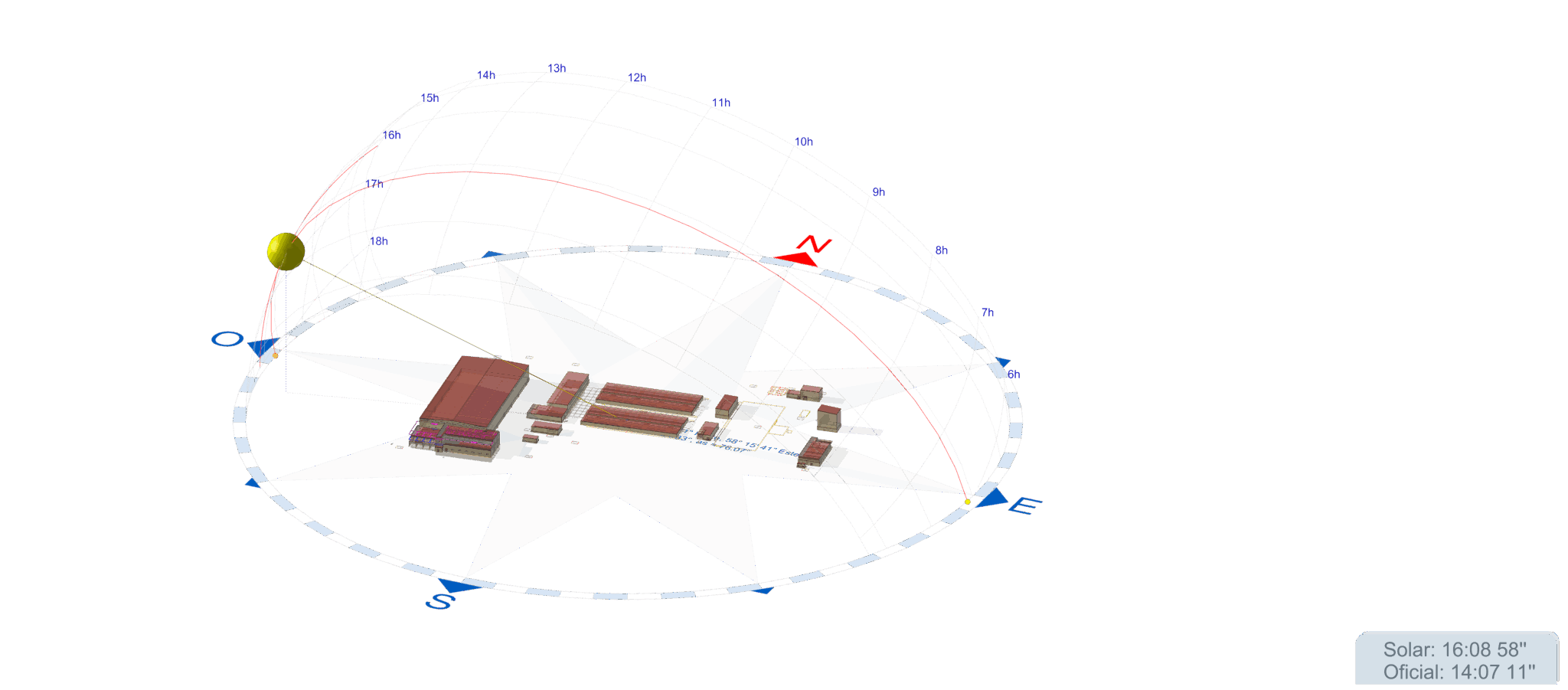

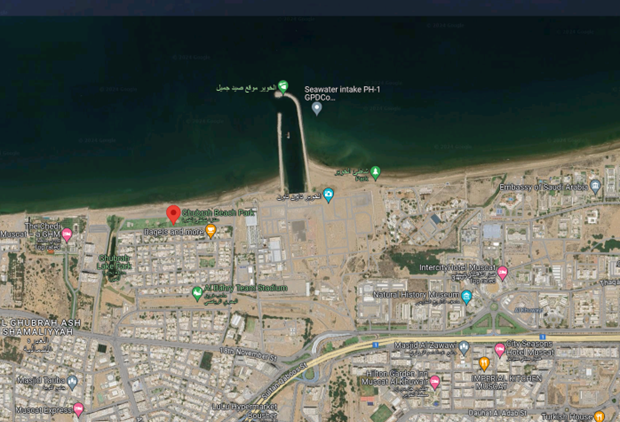

- Location: Muscat, Oman

- Key Data: Desalination capacity: 300,000 m3/day; Installed thermal power district cooling: 2 + 1 chillers of 828 kW each

- Technology: Water-cooled water chiller with inverter screw compressor

- Client: Inima

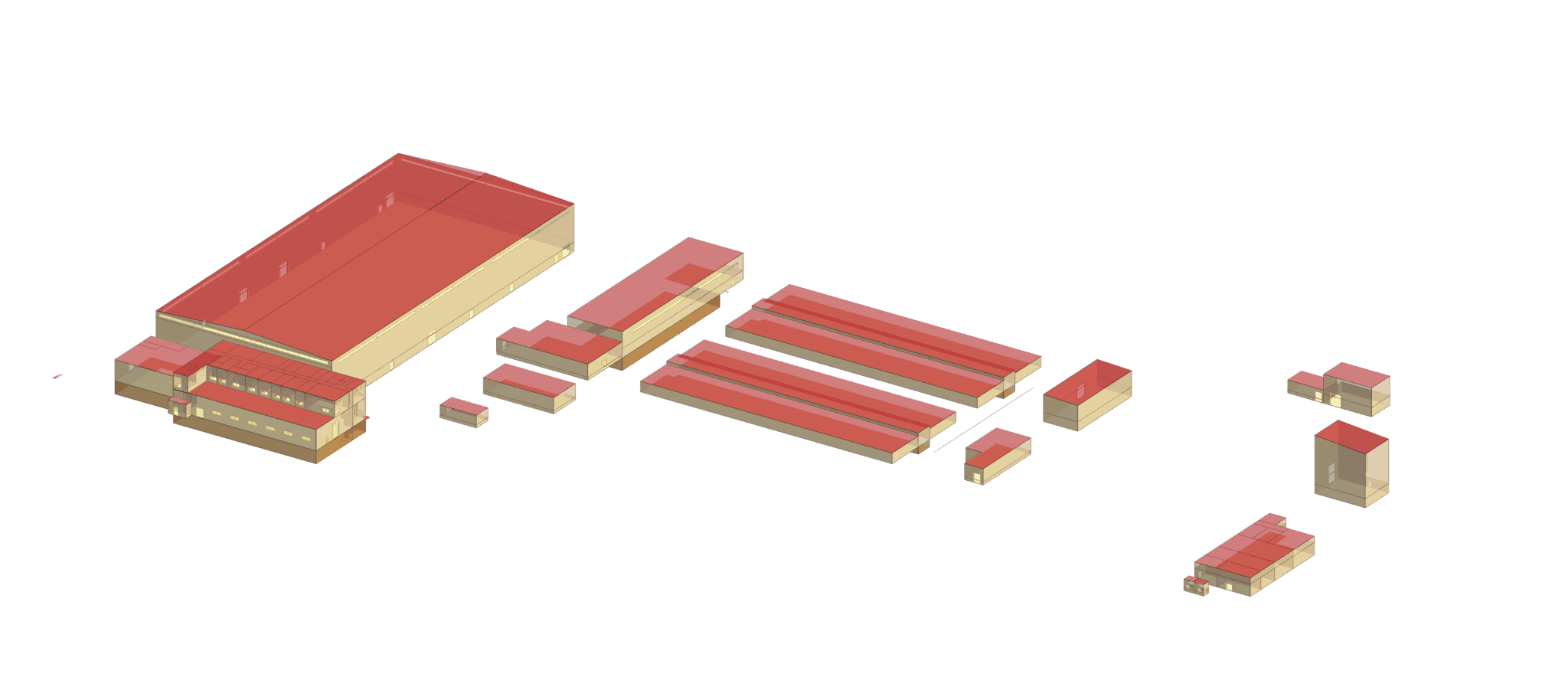

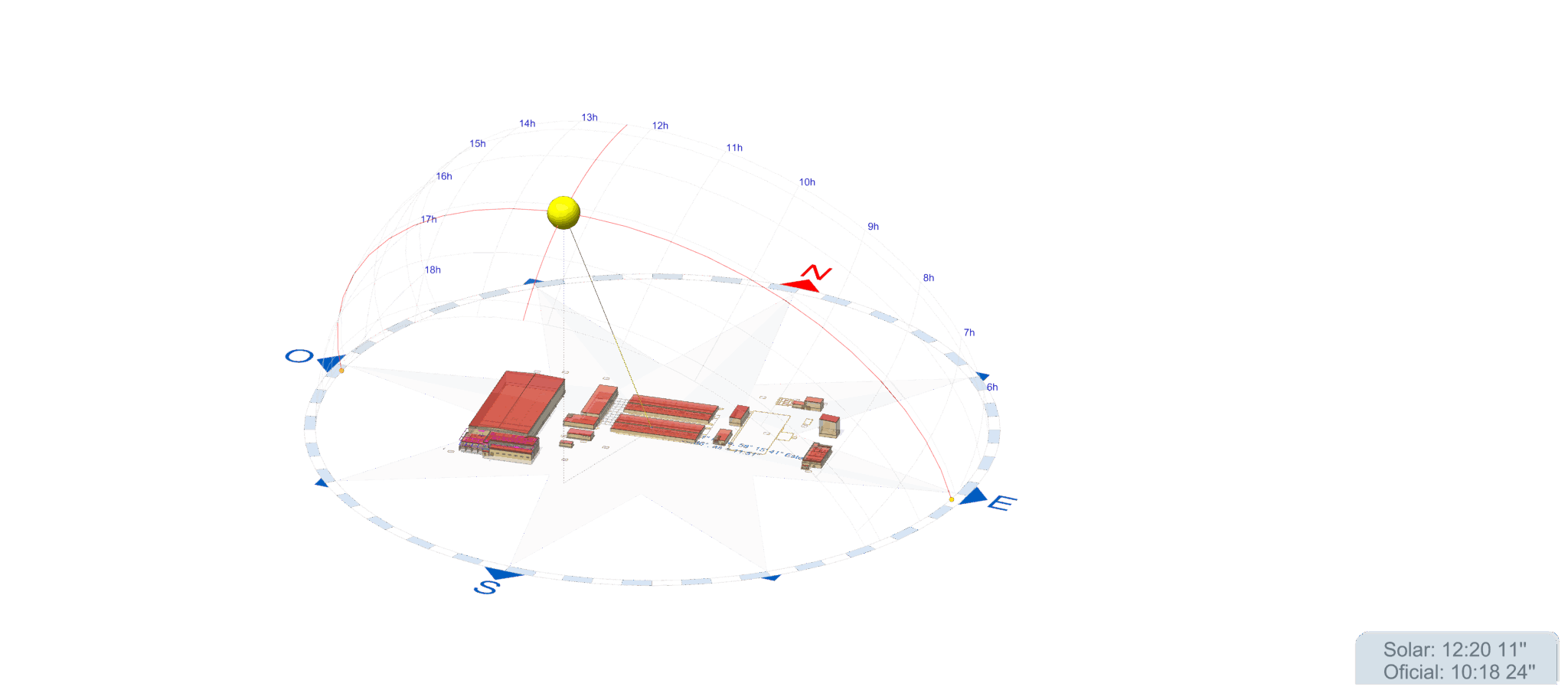

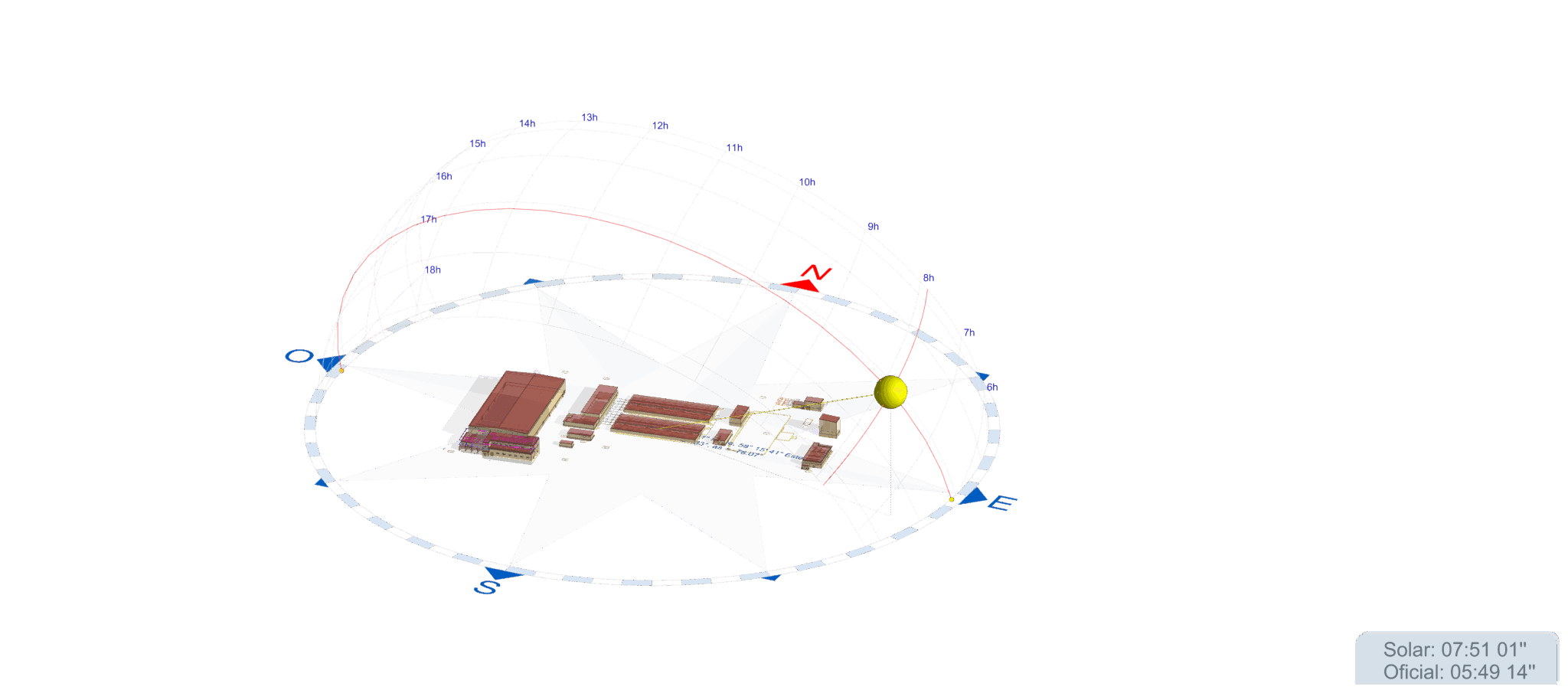

Savener has completed the design of the HVAC Project for the Ghubrah III IWP reverse osmosis desalination plant in Muscat, Oman. This industrial complex, of great strategic importance for the region, will have a highly efficient integral HVAC system, adapted to the severe climatic conditions of the environment and designed under the strictest international standards.

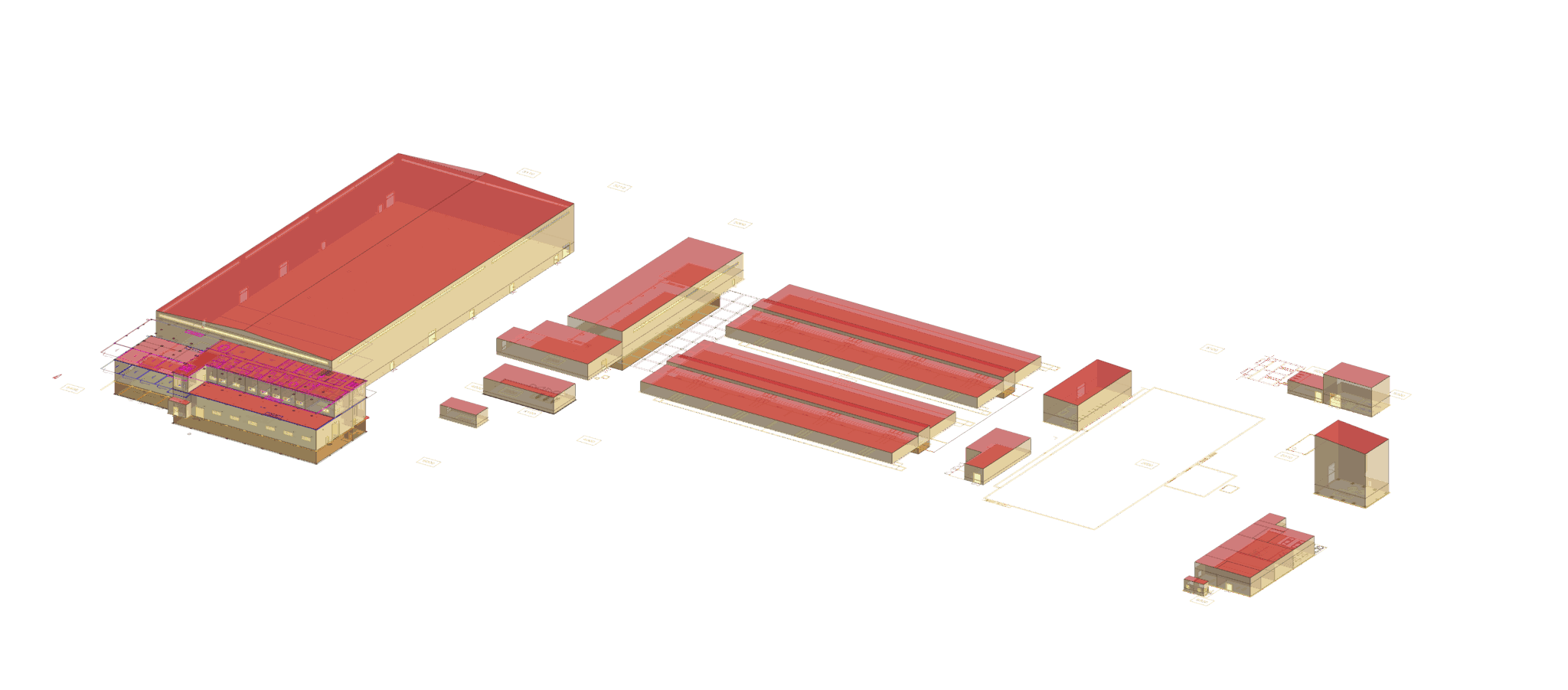

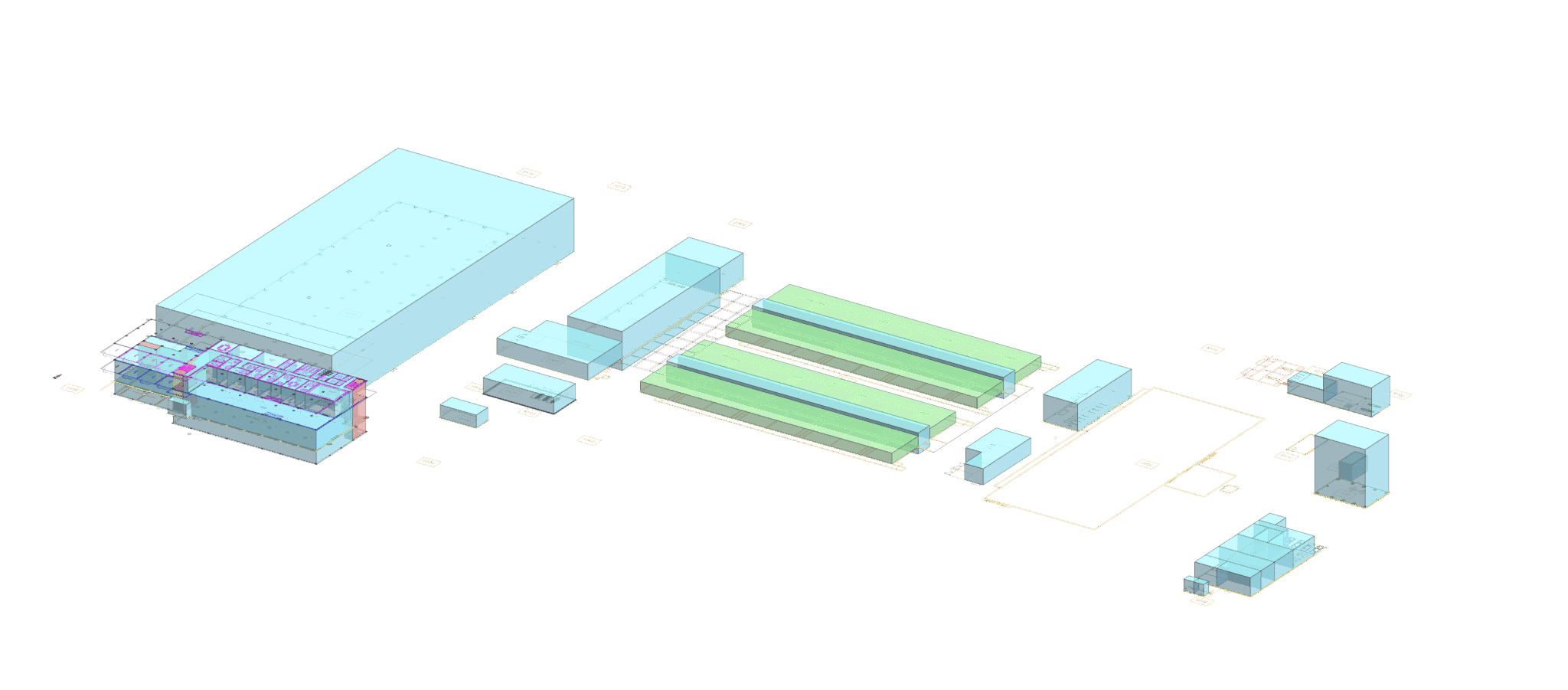

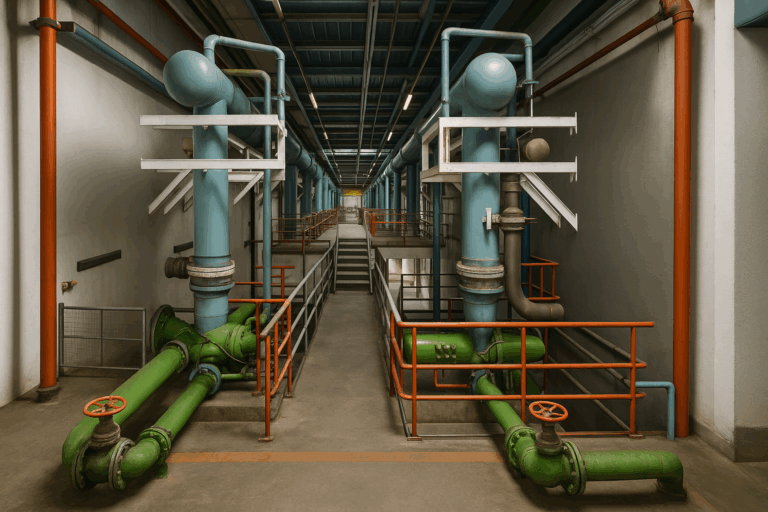

The core of the air-conditioning system designed by Savener revolves around a centralised chilled water solution, specifically configured to guarantee maximum efficiency and reliability in adverse environmental conditions. This system is made up of Water Cooled Water Chillers, which operate in a closed circuit with water cooled to 7/12ºC. The extracted thermal energy is distributed through a hydraulic network that feeds air handling units (AHUs and FAHUs) and fan coils strategically located in the most sensitive buildings, such as the Main Electrical Building, the Administration and Control Building, and other critical areas with continuous presence of personnel and electronic equipment.

The chillers are supported by a closed condensing water system, also using conditioned potable water, and a tertiary system based on filtered seawater, which allows for high thermal performance in a coastal environment. The entire package has been designed with redundancy, automated control, modulating capability and simplified maintenance in mind, including plate heat exchangers, variable speed pumps, pressurisation units, integral thermal insulation and control and monitoring systems fully integrated with the plant’s automation architecture.

In addition, individual air conditioning and ventilation systems have been designed, carefully selected according to the occupancy and thermal requirements of each area. These solutions range from variable refrigerant volume systems (VRF) and split-type units to adiabatic ventilation systems for industrial processes, guaranteeing energy efficiency and thermal comfort in each functional area of the complex.

The design also includes a wide range of auxiliary equipment and components – such as humidifiers, self-cleaning inertial filters, centrifugal and axial fans, and air-to-air energy recovery systems – all specified with criteria of maximum durability, ease of maintenance and compliance with local and international standards (ASHRAE, NFPA, IEC, GSO, among others).

With this project, Savener reinforces its international presence and consolidates its experience in the development of highly complex HVAC systems for large industrial infrastructures in demanding climatic environments, reaffirming its commitment to cutting-edge engineering, sustainability and technical excellence.