- Location: Getafe (Madrid)

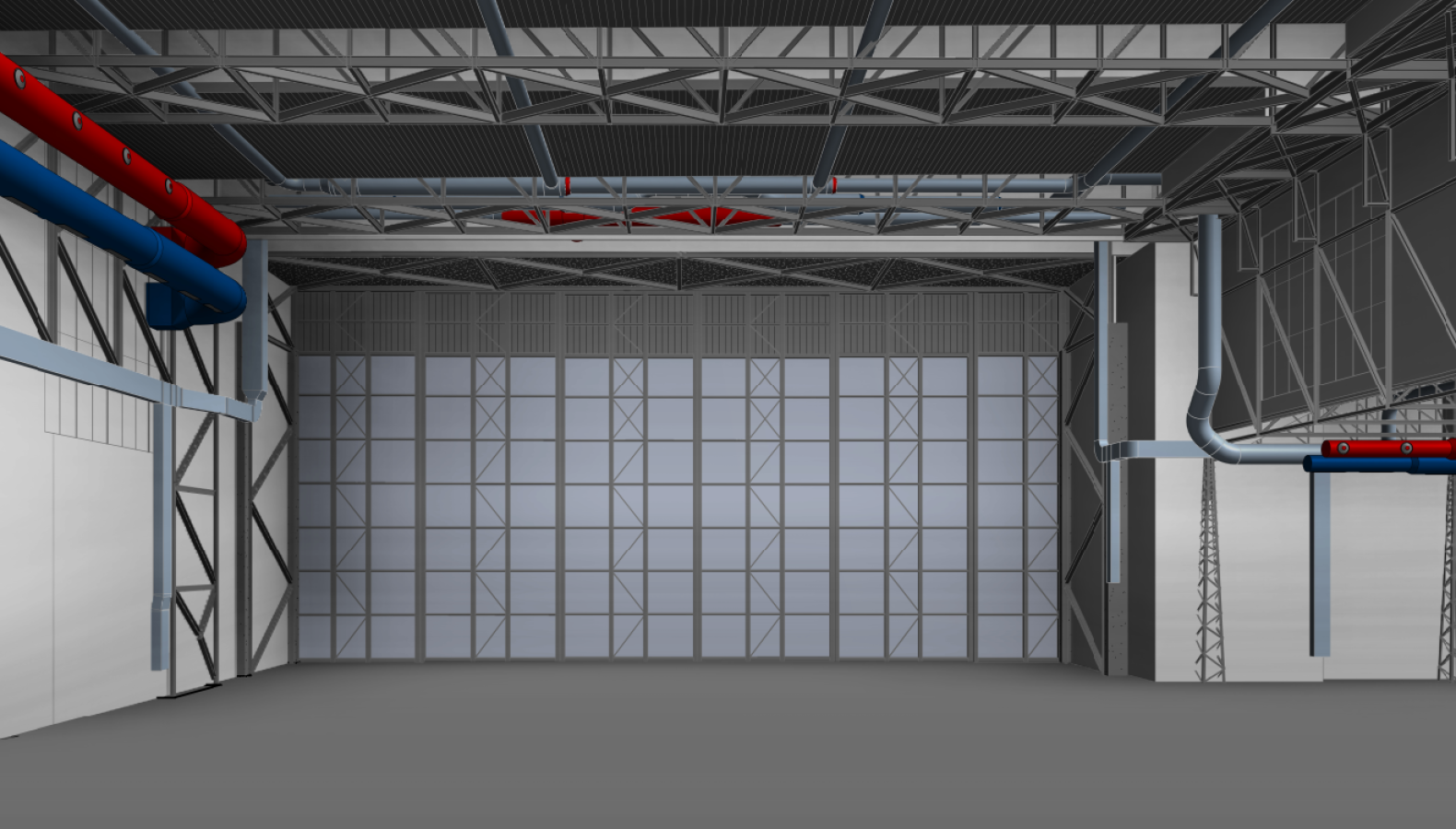

- Main Data: Production building of 11.280 m2, variable height between 10 and 18 m.

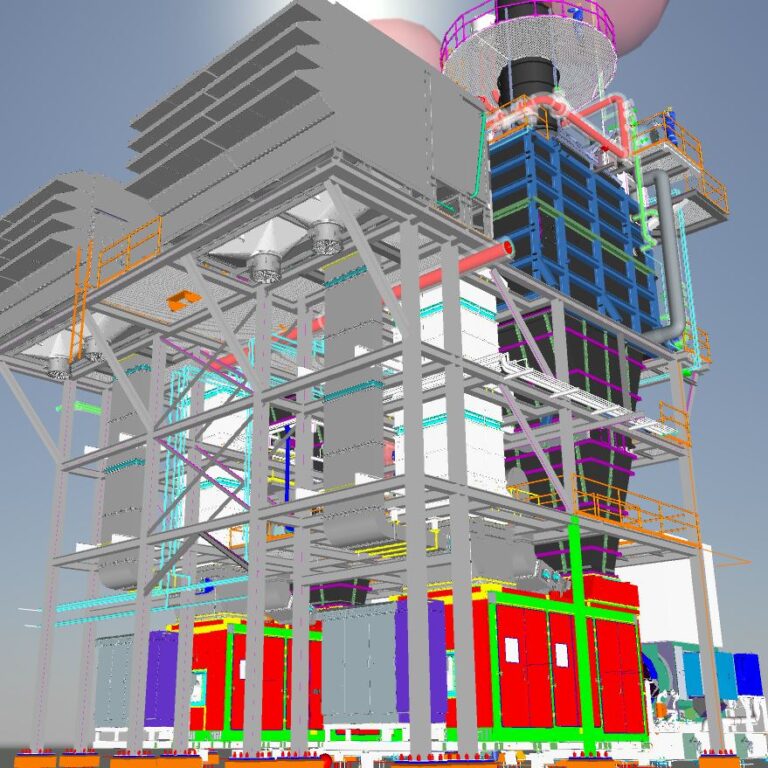

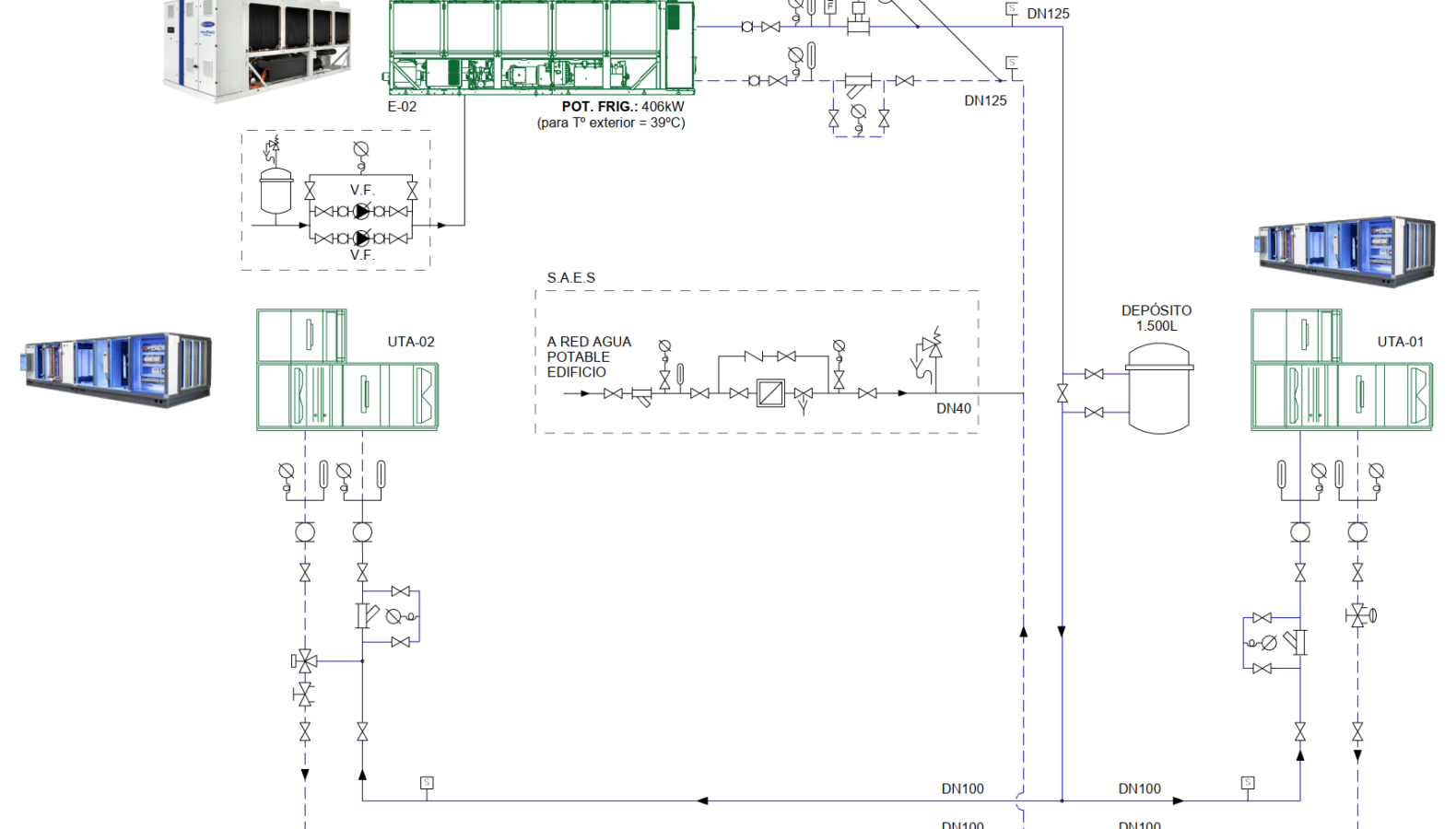

- Technology: Cooling only chiller plants with inverter screw compressors (2 plants x 406 kW + 4 AHUs x 200 kW)

- Customer: AIRBUS

The aim of this project is to update and optimise the air conditioning and ventilation installations in the D04 building at the Airbus factory in Getafe, an action included in the battery of energy improvements in its infrastructures, continuing with the process of decarbonisation of its factories.

The main reason for the refurbishment of the building is that the existing installation has a serious problem of installed thermal power and does not meet the thermal demand of the building, which means that it is not possible to maintain the interior comfort conditions inside the hangar.

The D04 building has a surface area of 11,280m2 and a capacity to house 4 A400M aircraft. After an extensive audit by a multidisciplinary team of Savener specialists, where different alternatives were studied and assessed to meet the needs of the project, ranging from the complete reform of the system to specific solutions that would significantly improve the comfort of the ship, the proposal finally chosen was the latter. Maintaining part of the existing installation, designing a new complementary one.

Currently there are radiant panels on the ceiling which were designed for heating, but which are now also used for cooling, with the disadvantage that they leak due to water condensation caused by the working temperatures, causing serious damage to the aircraft, so that this part of the installation is not suitable for use in the summer months. In addition, the current installation based on AHUs is undersized because they take into account the power of the panels, which cannot be used due to the original bad design, the power of the AHUs is insufficient and cannot handle the entire thermal load of the aircraft.

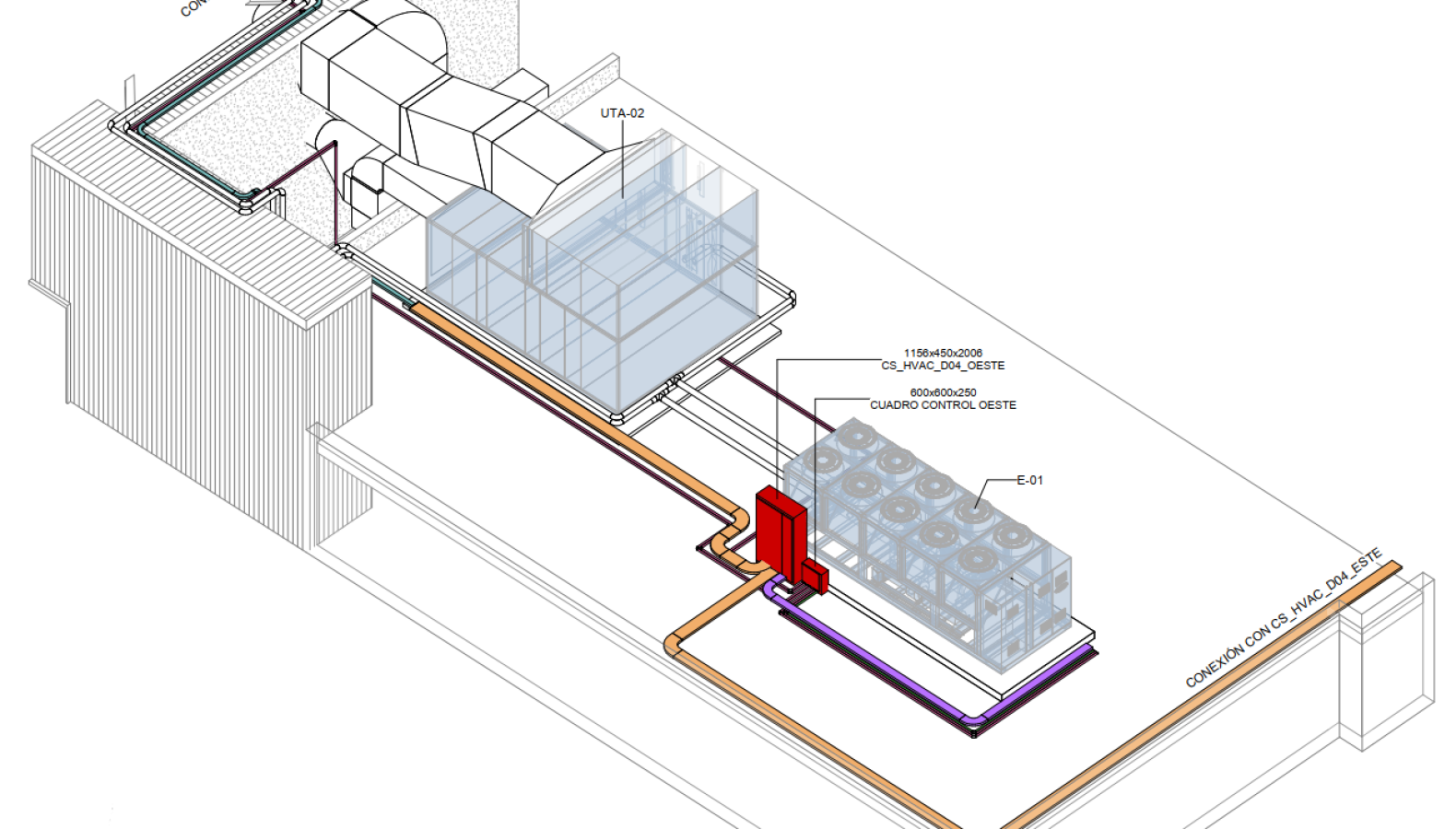

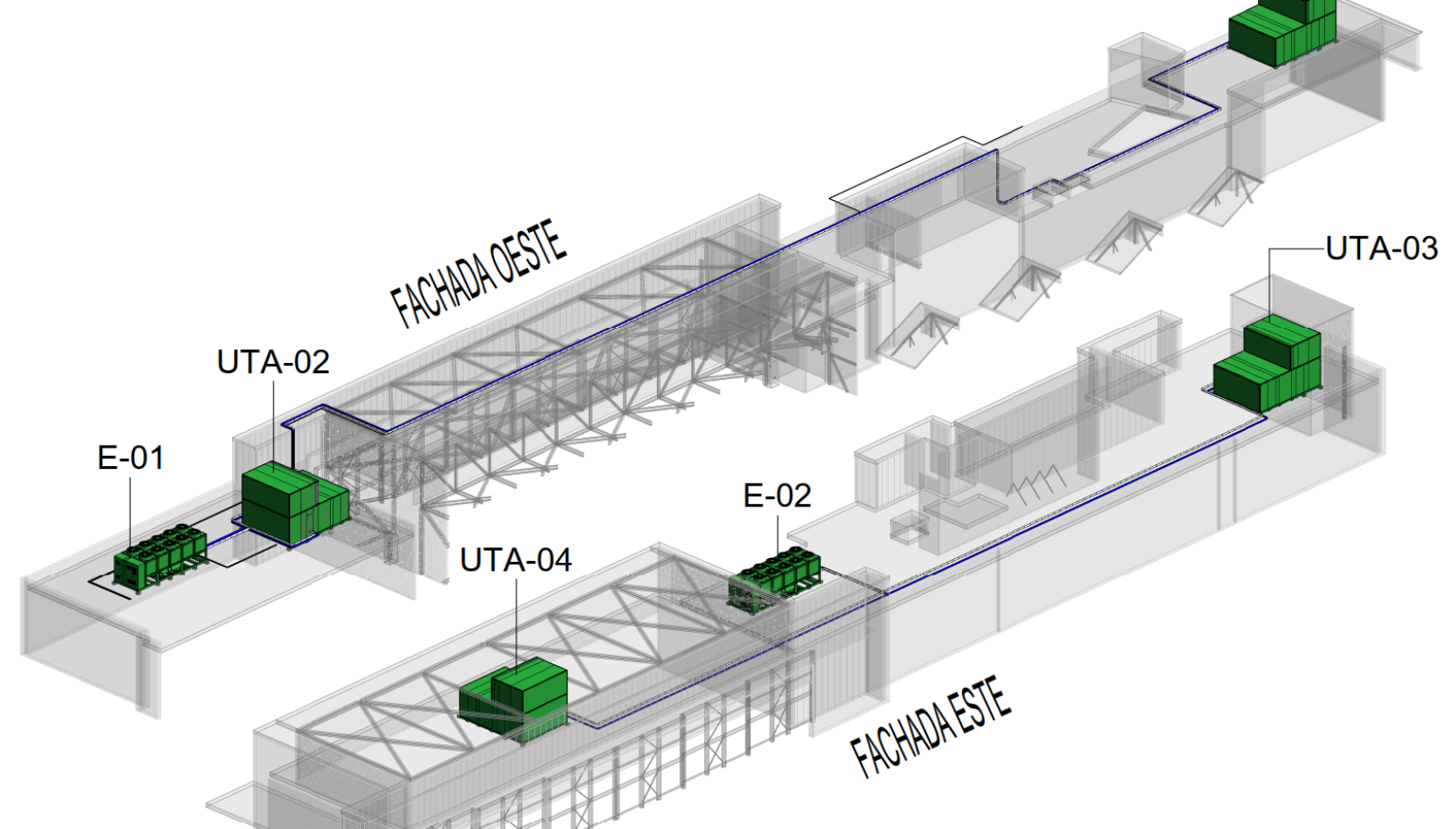

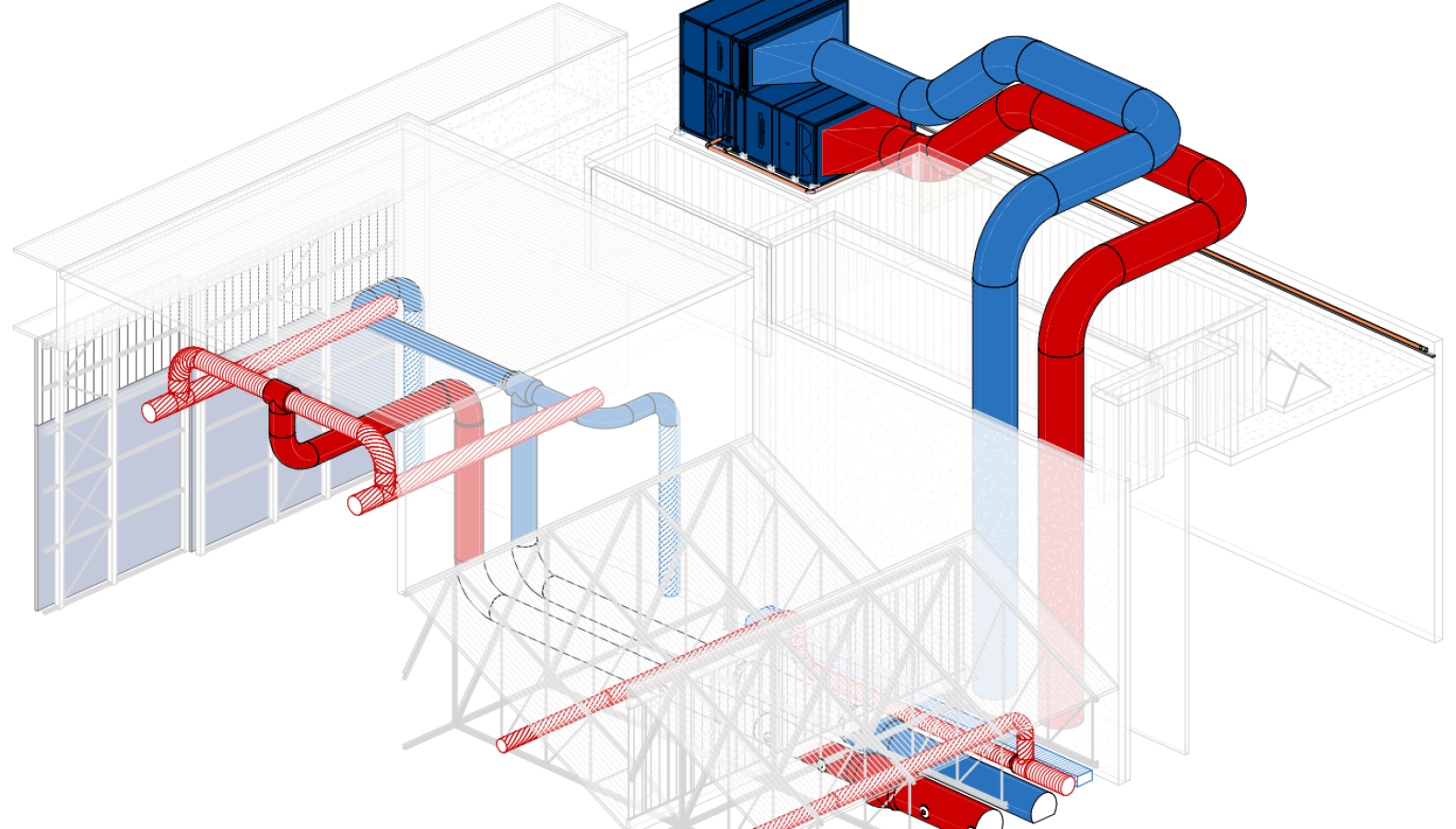

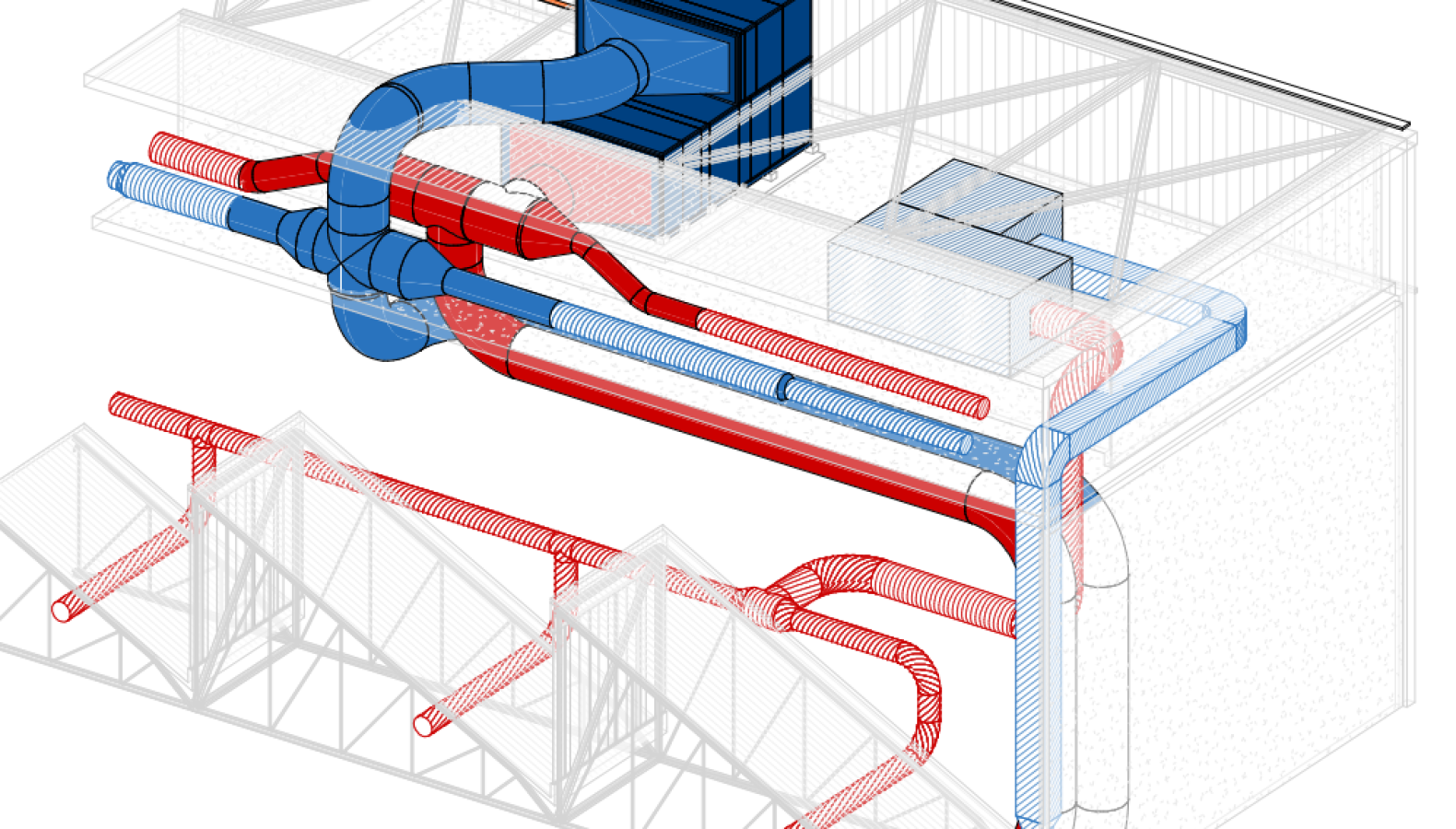

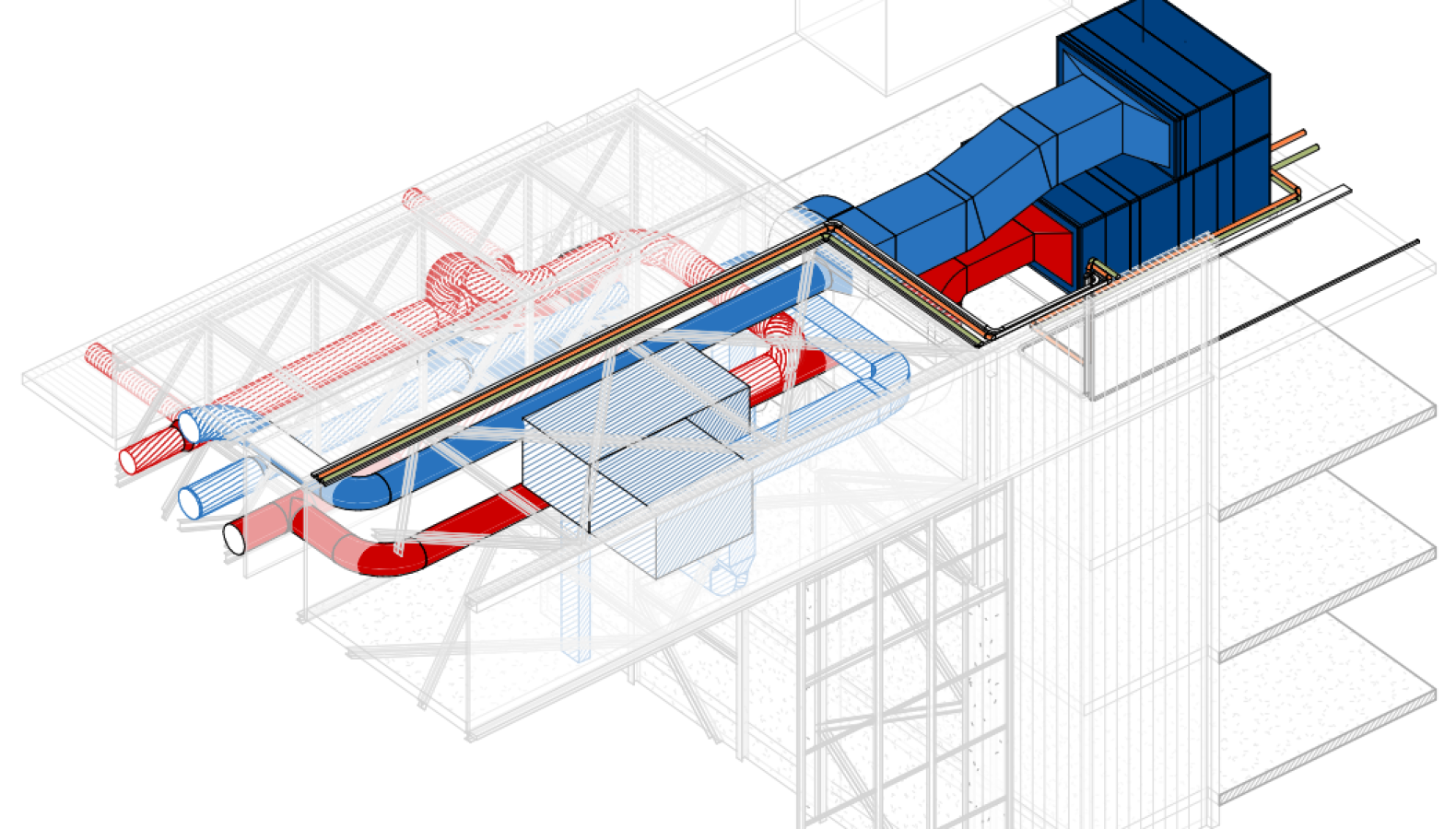

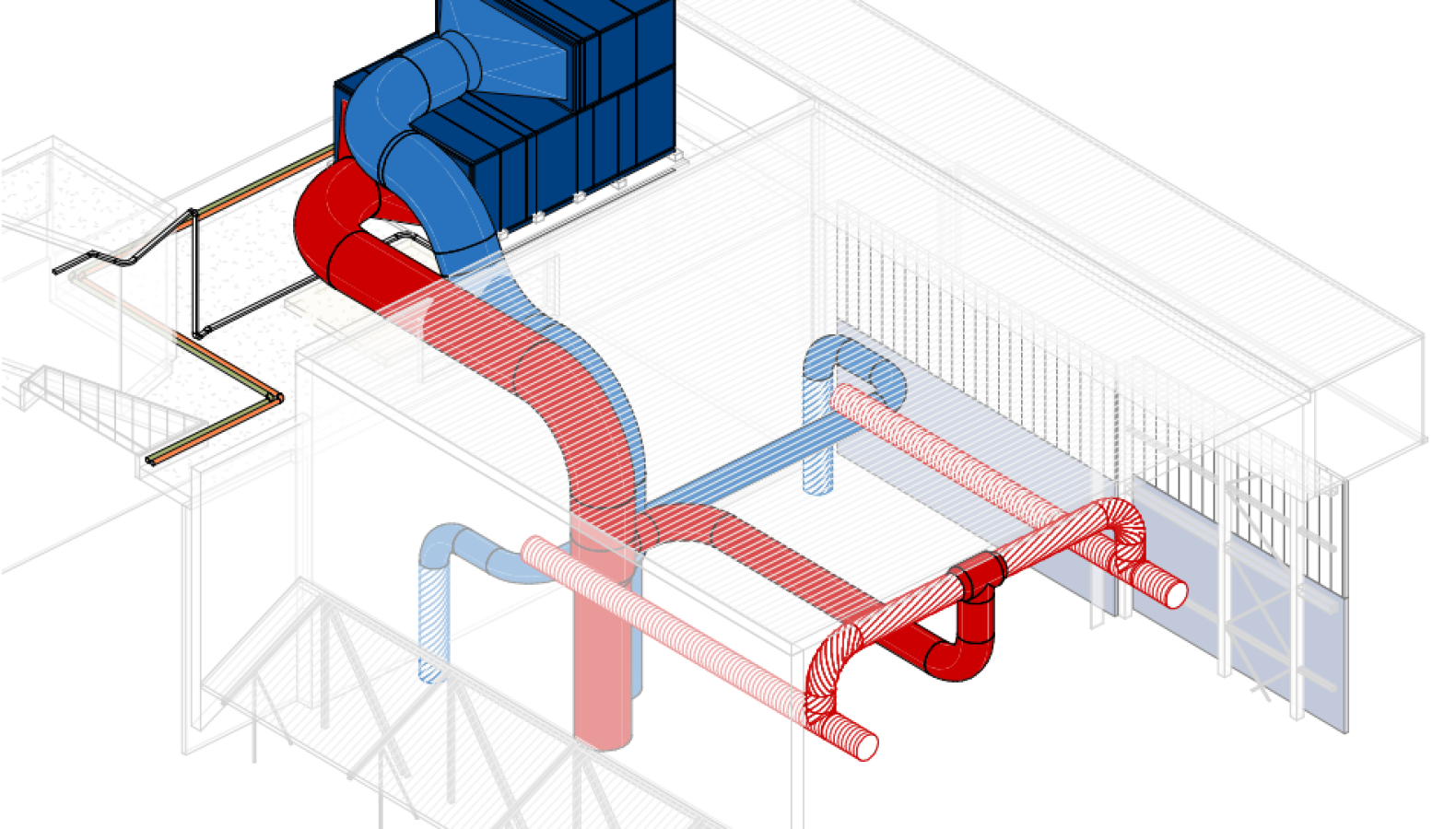

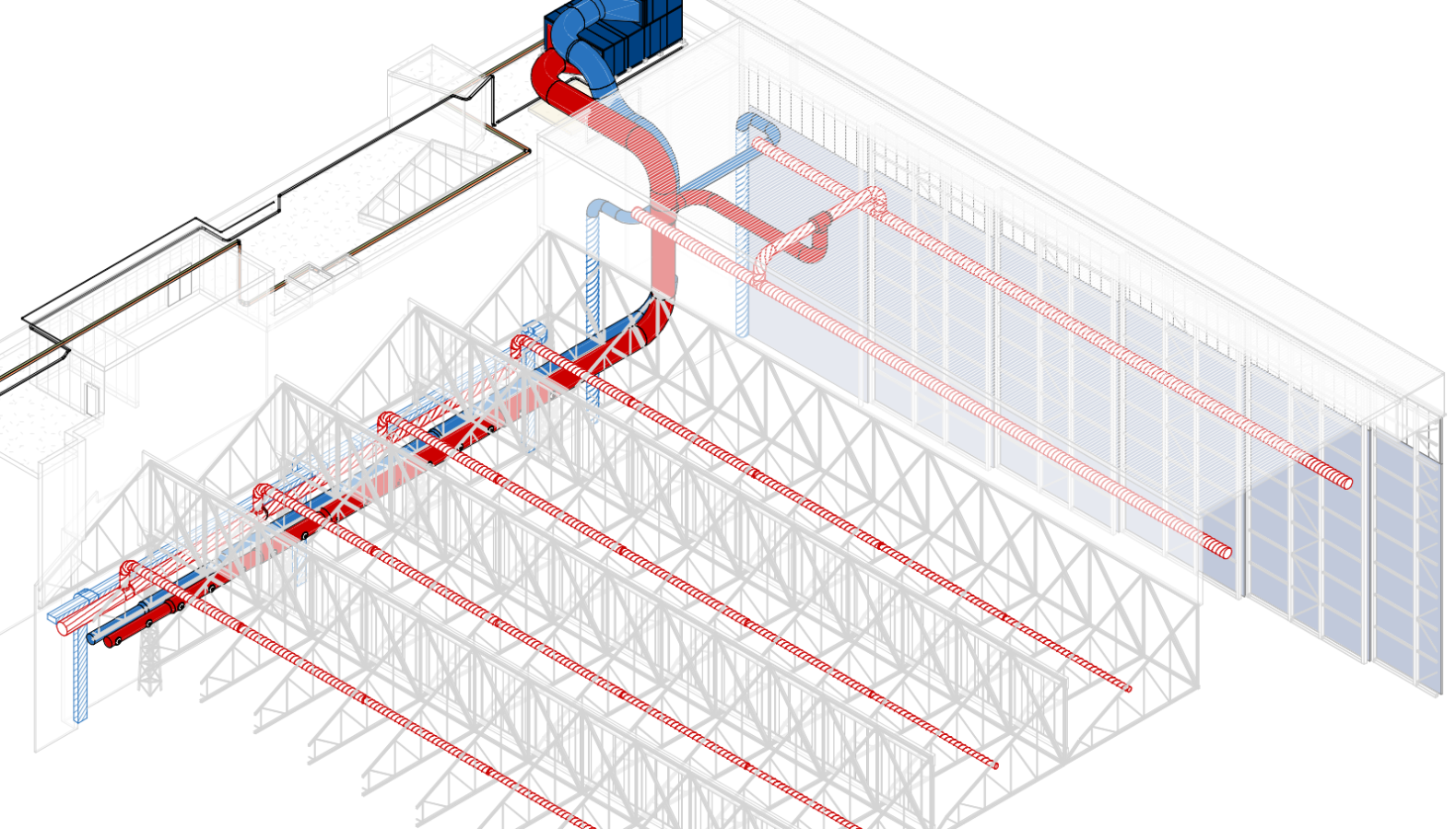

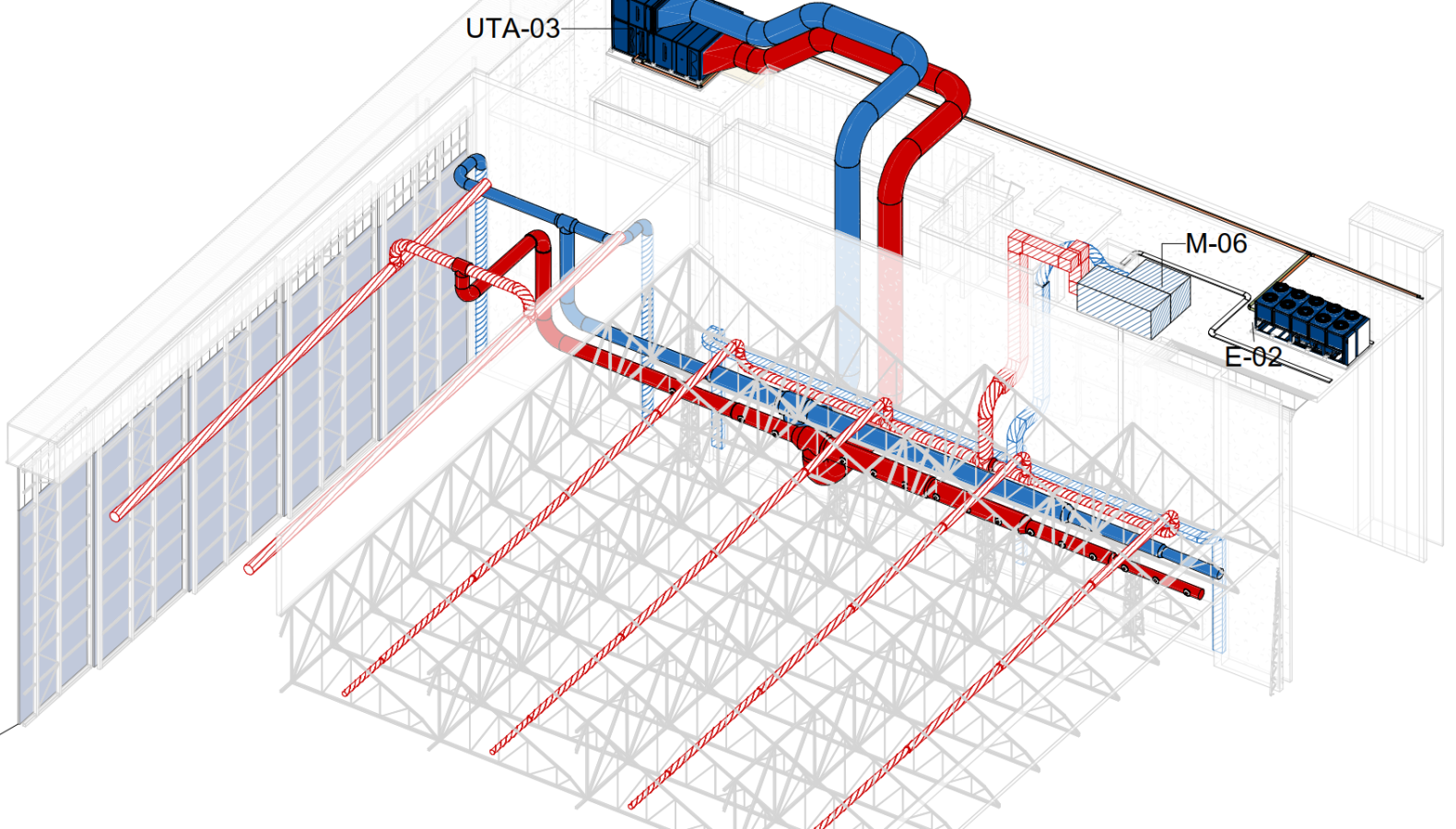

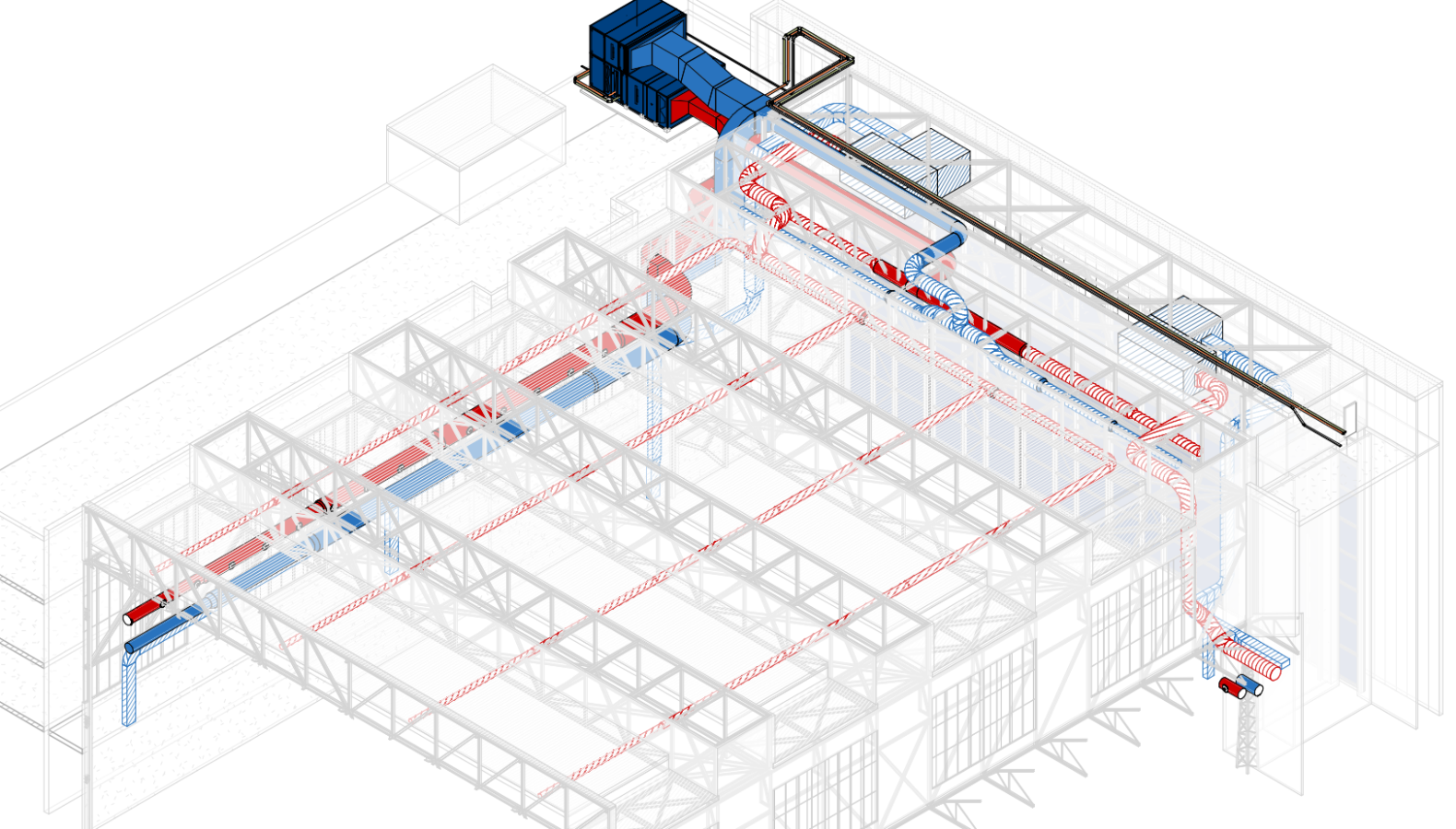

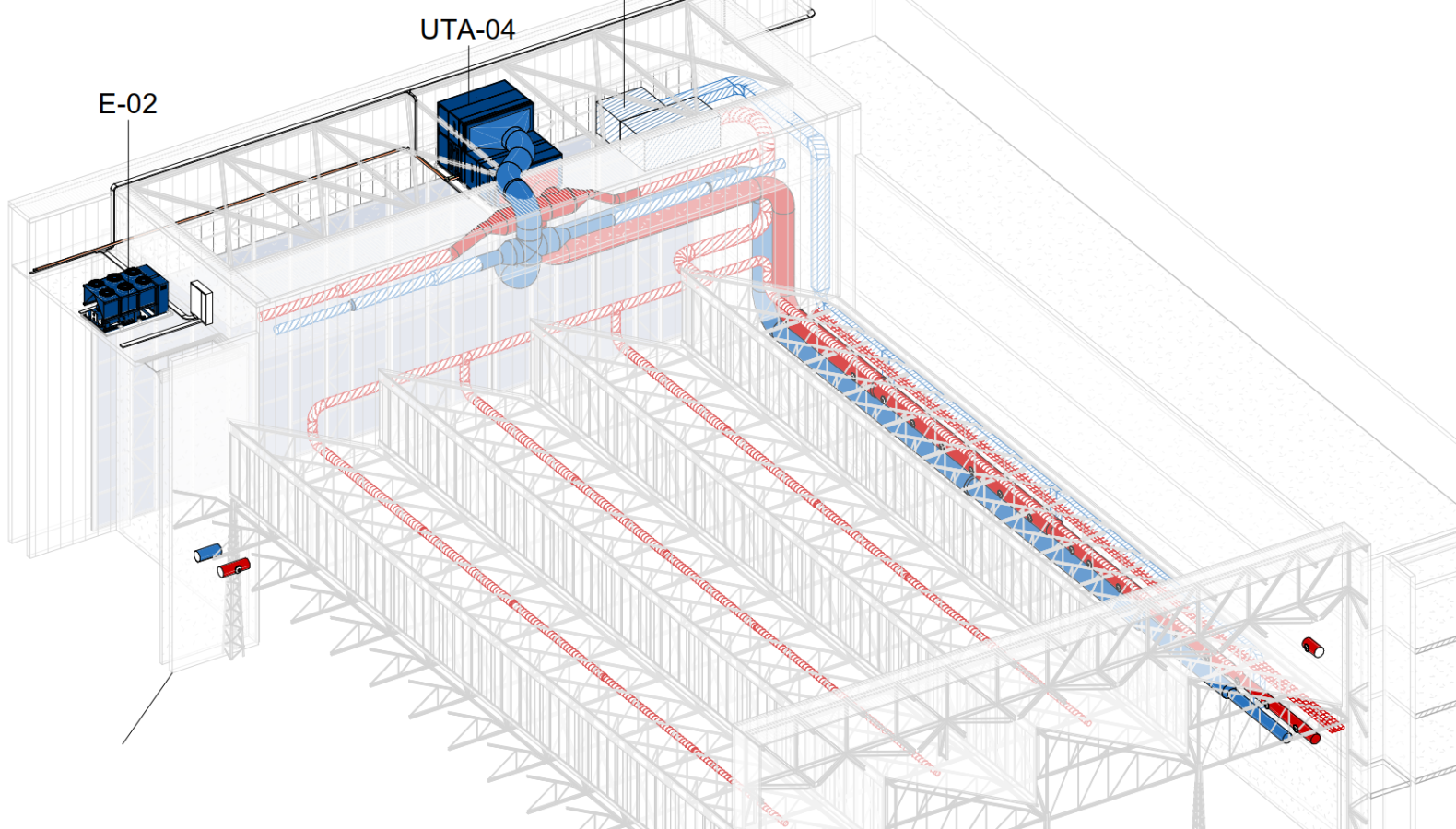

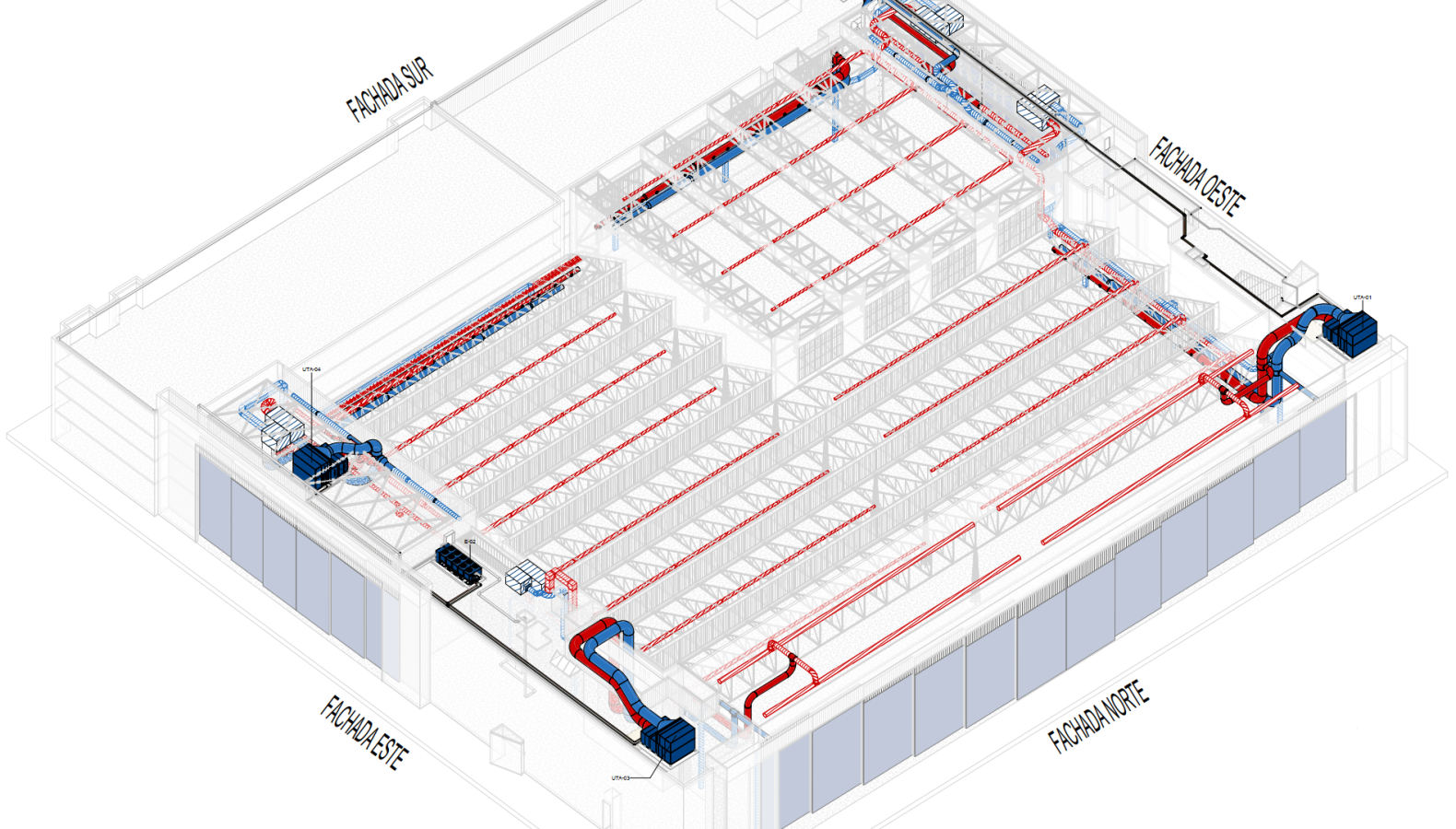

In view of this situation, the following solution is proposed. From the HVAC installation point of view, the D04 hall of the Airbus Getafe Factory is organised in four quadrants: NE, NW, SE, SW with the aim of treating each quadrant independently. Given this power deficit, the solution proposed was to equip each of the quadrants with a TROX AHU, with the premise of invading the production area as little as possible, as one of the essential conditions of the client was that the work could be carried out without stopping production in the building, so perimeter systems were chosen based on AHUs on the roofs of the outbuildings with perimeter ducts in the production area for the treatment of the interior air.

For the production of the cooling that supplies these AHUs, two chiller plants have been planned, one on each façade. These are cooling plants with Carrier inverter screw compressors, due to their excellent performance both in terms of power and efficiency. On the East façade, two AHUs and a chiller plant have been installed to supply cooling to these two machines, and on the West façade, a symmetrical system, two AHUs for the treatment of interior air and a chiller plant which is responsible for producing the cold water for cooling the air in the AHUs.

It is also important to mention that, although the installation is a cooling production system independent from the existing one, the projected installation takes advantage of part of the existing installation, specifically the air distribution networks, where the new ducts are connected to the existing sections to improve the distribution of the treated air and the indoor comfort conditions.

Preliminary design and project were carried out in 2023 and are planned to be executed in different phases over the next 2 to 3 years.

With this solution, Savener aims, in addition to optimising the energy consumption of the HVAC systems, to improve their operation in order to guarantee their correct operation and to meet Airbus’ high standards at all times.