Savener, after having already developed in 2019 the Strategic Plan of Energy and Emissions Reduction Measures for Airbus factories in Spain, framed within the Energy Performance Vision 2030 Airbus Operations Project, has developed this year 2021 the design of some of the measures set out in this plan for its execution.

Airbus, whose environmental commitment objective is to reduce 30% in Energy and 65% in CO2 emissions, taking 2015 as a starting point and the year 2030 as a horizon, in its Operations Factories (AIO), has counted on Savener’s extensive experience in Energy Saving as a firm ally.

The three projects designed, which are described below, will achieve important results in the fight against Climate Change. With them, Savener and its specialised technical team will contribute to the achievement of the objectives set by Airbus, once they come into operation in the different Factories that the company has in Spain.

Refurbishment of the HVAC system in Hall A of the Tablada Factory, Seville.

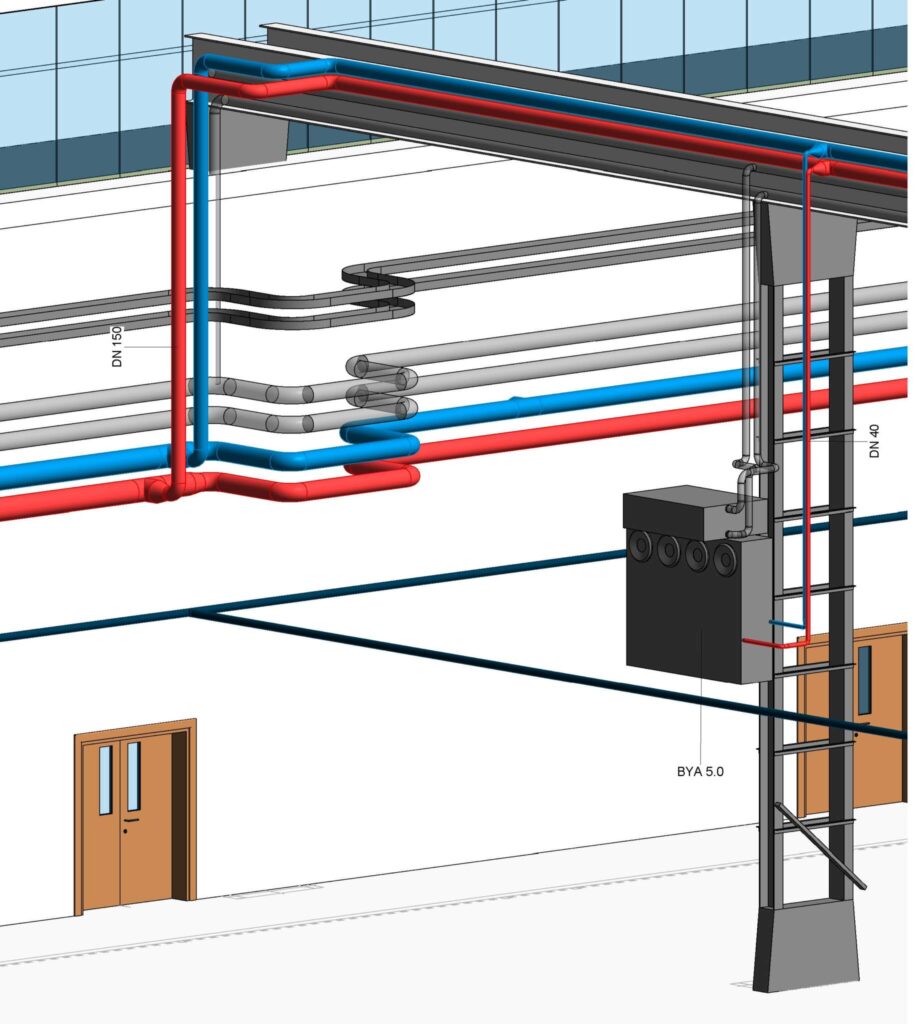

In this project, the hydraulic network of interior water air-conditioning in Tablada’s Building A and the 90 existing fan-coil air-conditioning units are replaced by new, more efficient ones that entail lower electricity consumption and incorporate a variable air flow system. In addition to these units, there is the incorporation of flow regulation valves, more advanced control of the HVAC system, which is integrated into the plant’s BMS, and the new insulated network that prevents energy losses.

At the same time, and with a goal not only focused on energy efficiency, but also on the well-being of people, a new more efficient forced ventilation system is planned, the main objective of which is to improve the quality of the air inside the building, in accordance with current regulations. For this purpose, 2 Air Treatment Units with variable flow, freecooling capacity and integrated heat recovery are planned.

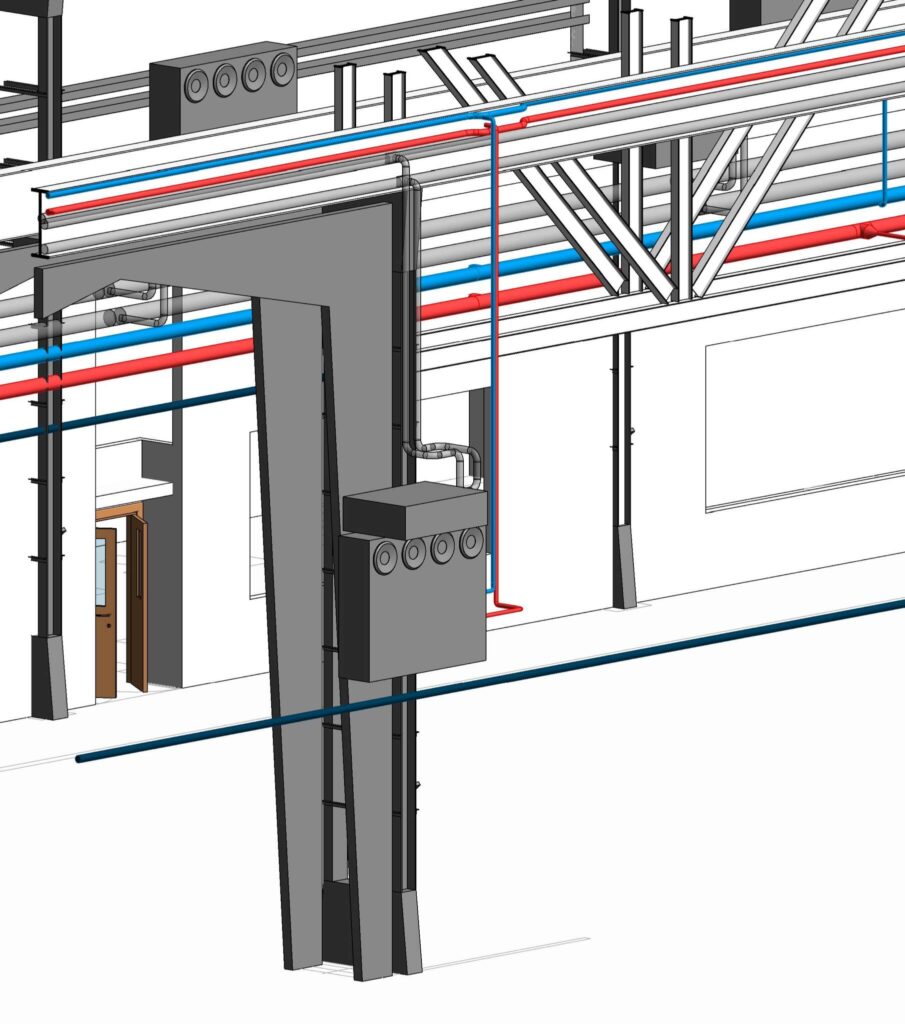

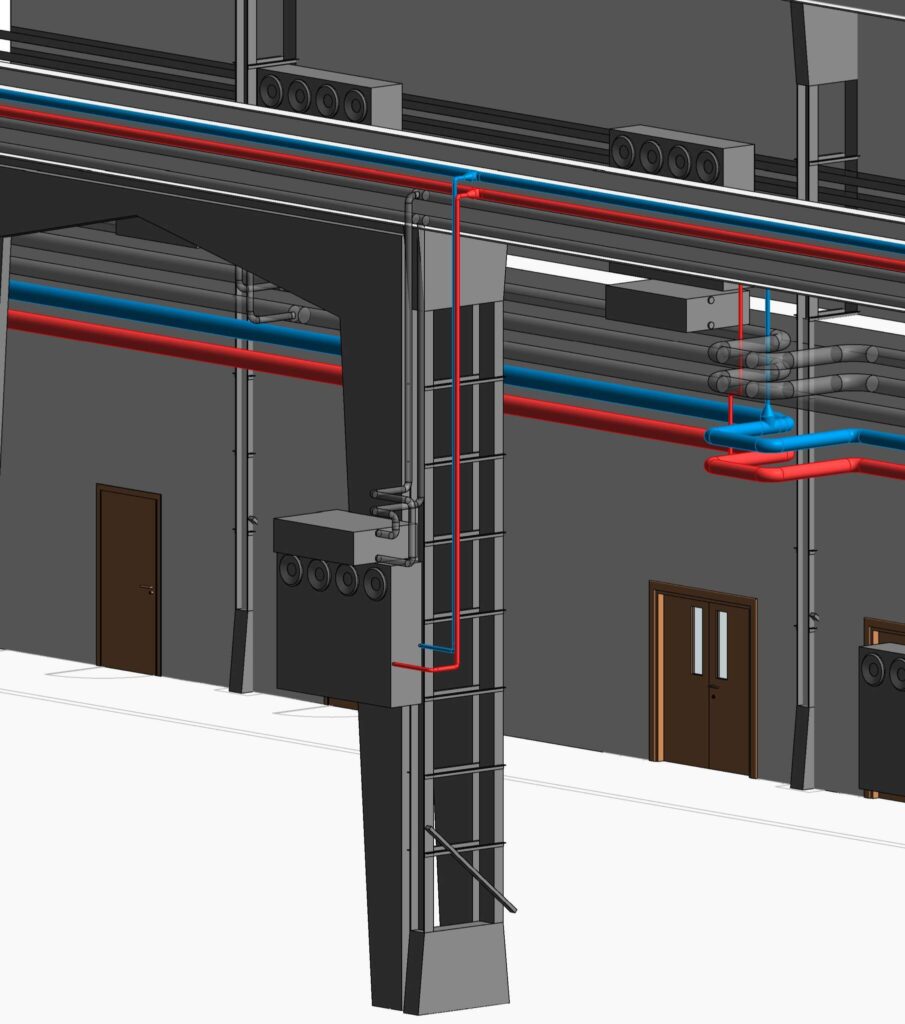

This project has been developed using the most advanced techniques in 3D Modelling, such as 3D Laser Scanning, which has allowed us to model the existing air conditioning network in detail. Having such a realistic model allows us to design a solution that foresees possible interferences with the existing installation, thus simplifying the implementation of the new system, without the need to stop the operation of the current one.

Reform of the HVAC Control System of Hangars H1.1, H1.2 and H2 of the San Pablo Sur Factory, Seville.

The Air Treatment Units for air conditioning in Hangars H1.1, H1.2 and H2 of the Airbus San Pablo Sur Factory, although they are in use and their replacement is not yet prescribed, currently present deficient operation and management.

As energy improvement measures for these units, it is planned to equip the fan motors with variable speed drives and improve their operation in free-cooling mode. In addition, a complete update of the existing control architecture and most of the field elements of the Air Treatment Units has been planned in order to integrate the new control system in the current BMS of the San Pablo Sur Factory, which will allow better programmed management of the equipment and therefore, in combination with the possibility of operating at variable flow, thanks to the incorporation of the variable speed drives, obtain a reduction in electricity consumption in the fans of these units.

New Biomass Steam Generation Plant at the Airbus Illescas Factory, Toledo.

The Airbus Illescas factory has numerous air handling units (AHUs) that require a steam supply to maintain the thermo-hygrometric conditions of the spaces within the set values throughout the year. At present, steam is generated by autonomous “Hygromatik” type electrical equipment attached to each AHU. These elements have a high electricity consumption and require constant maintenance.

The project is a major step towards achieving Airbus’ goals. The strategy of efficient units and the use of Biomass as pillars of the final solution will provide a 96% reduction in CO2 emissions and 20% reduction in energy consumption, compared to the emissions and consumption of the existing system.

With the completion of these three projects, designed by Savener and its team of highly specialized professionals, our company continues to consolidate its position as a benchmark in Highly Efficient Solutions for a sustainable and more humane development of the Planet.