Savener, a renowned multidisciplinary engineering company, has carried out an ambitious project at the Airbus factory in Getafe to address the challenges of energy loss in Hangar A1, used for the A320 production line.

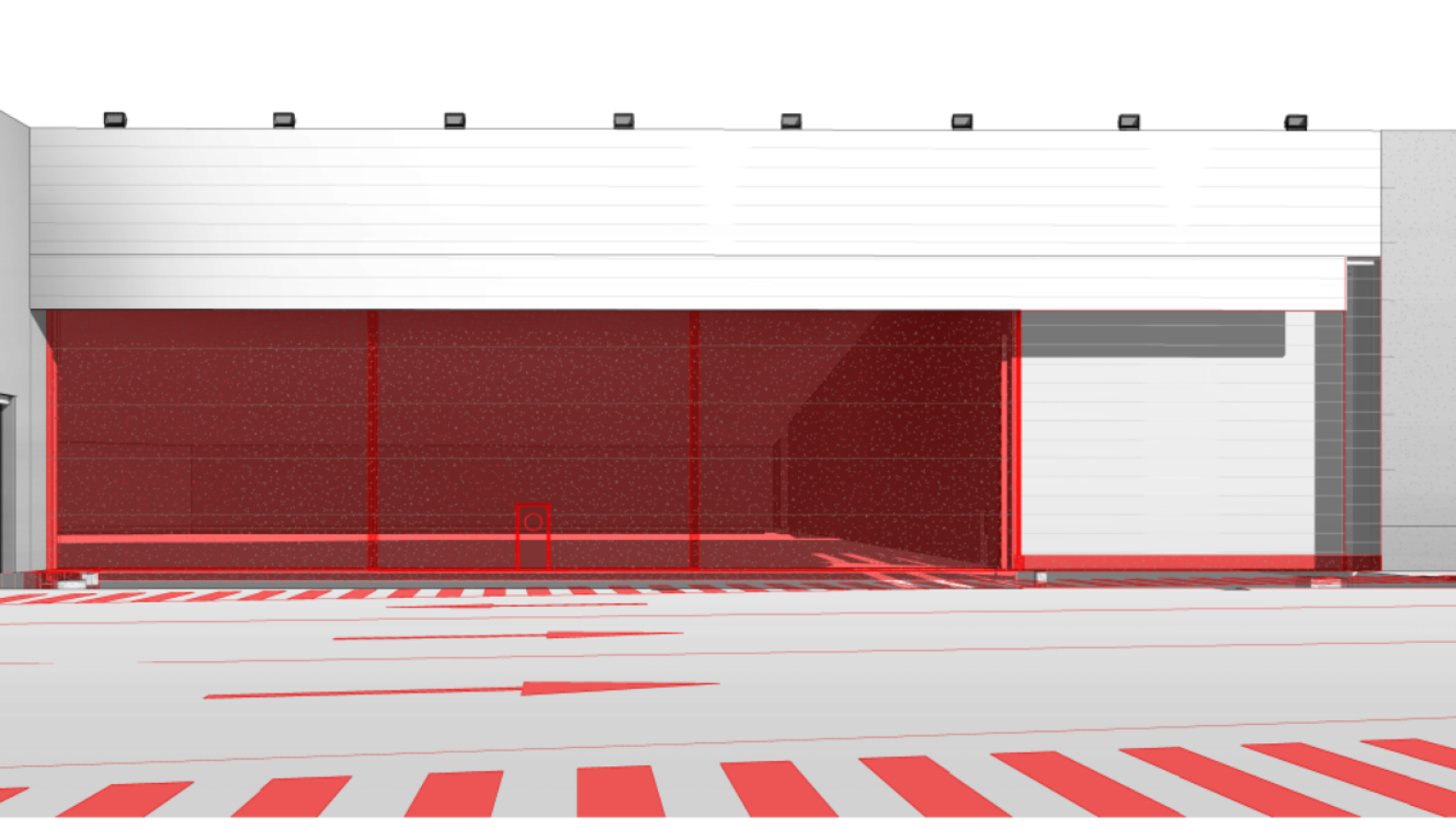

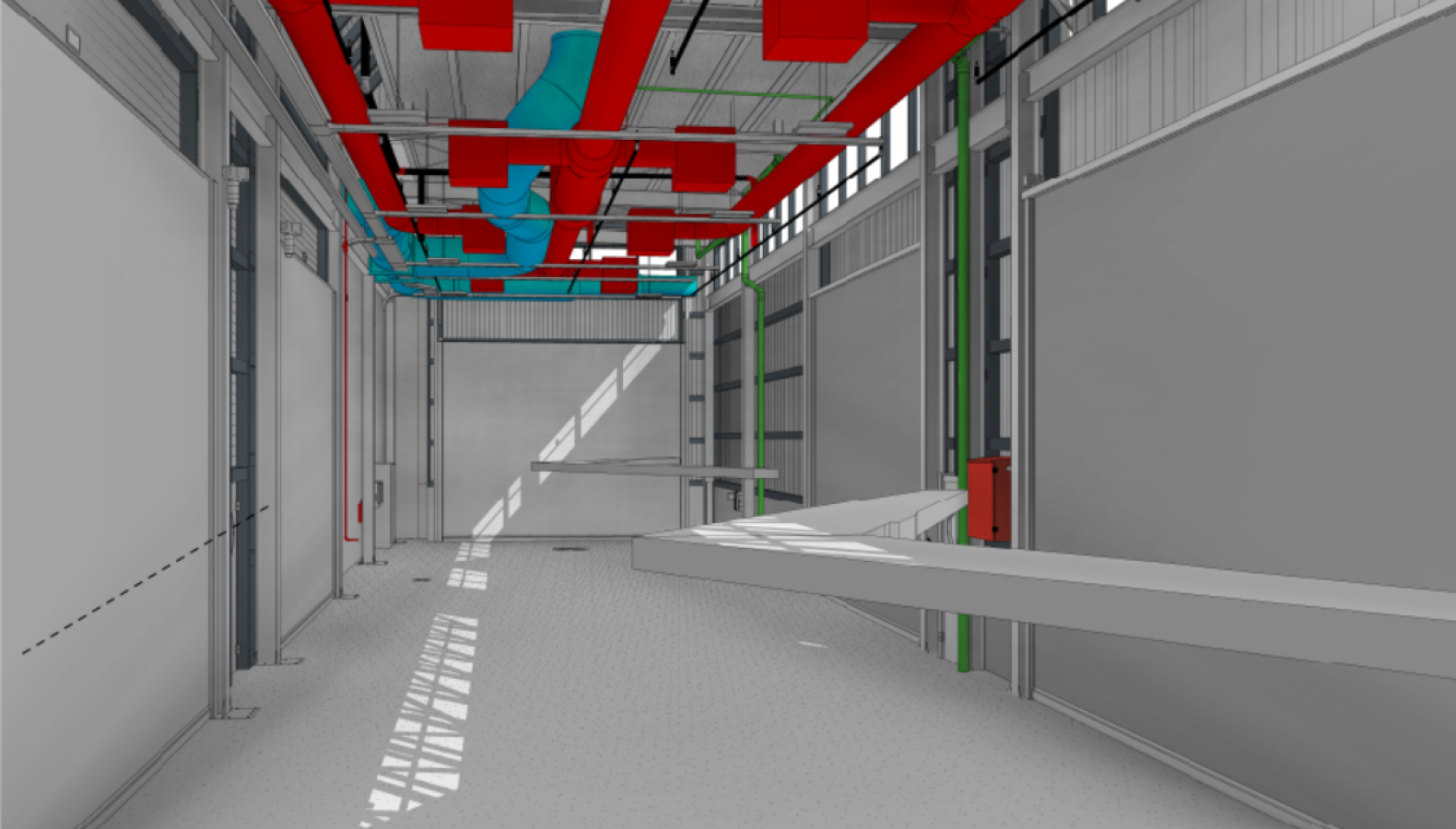

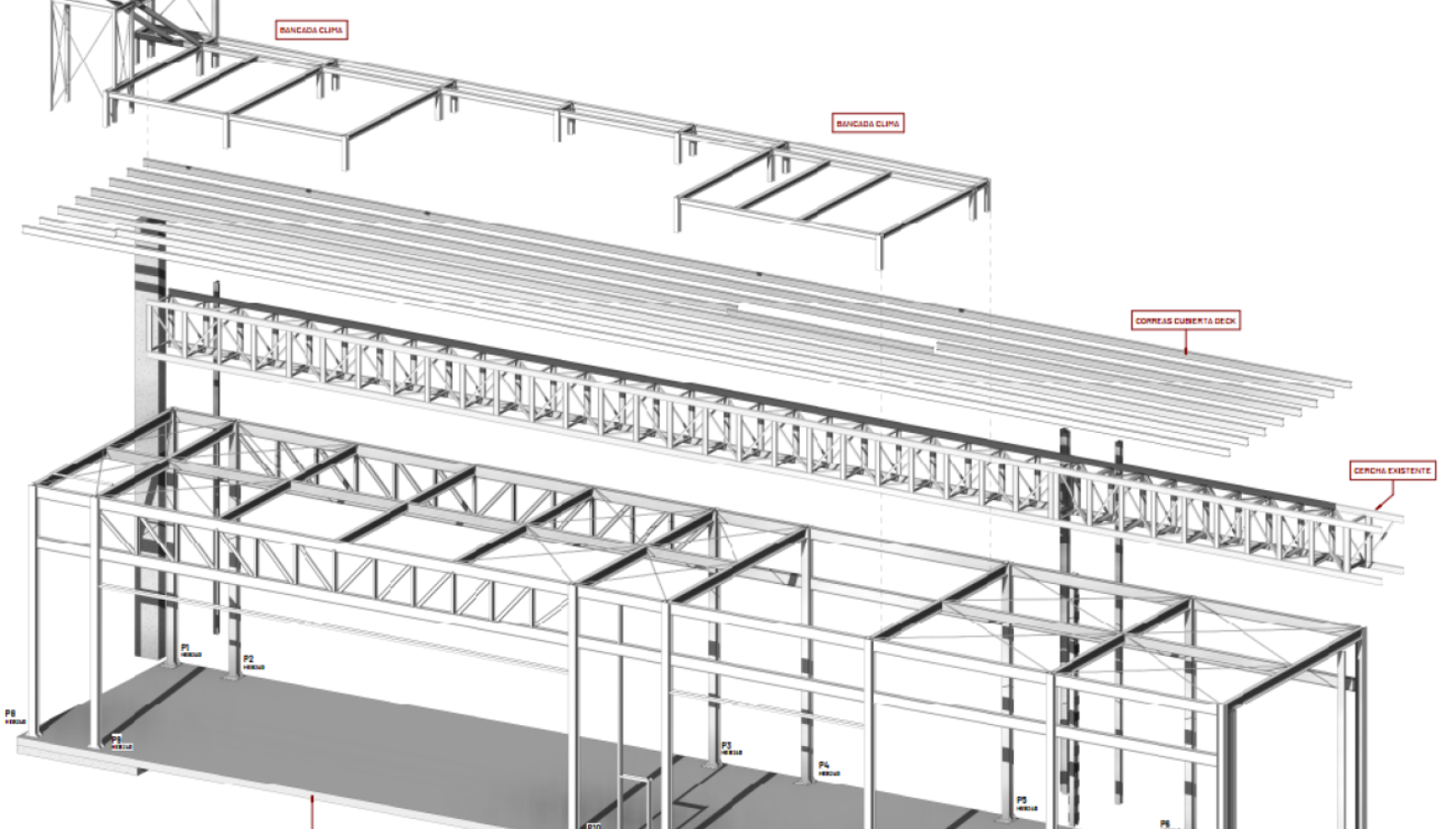

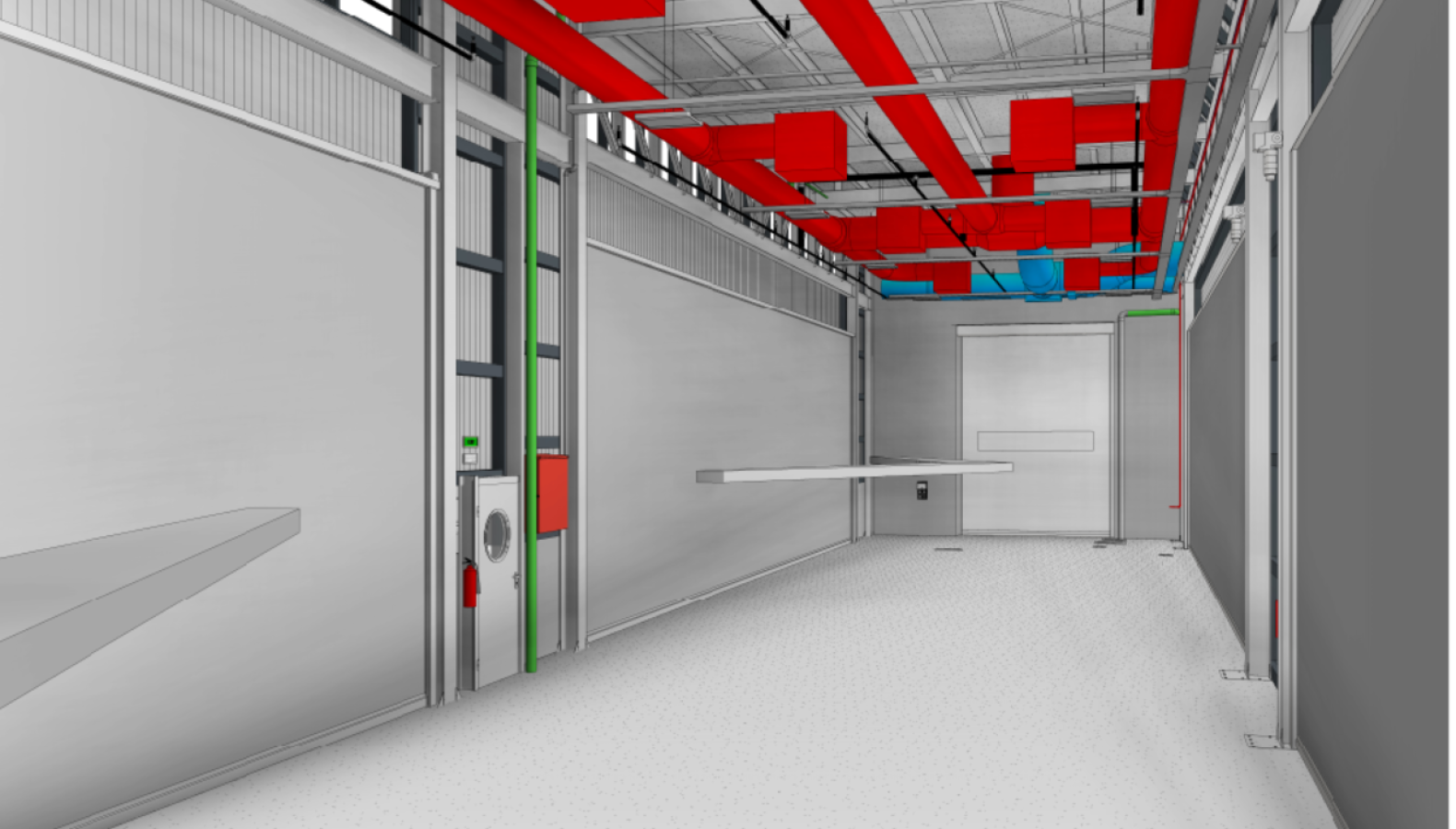

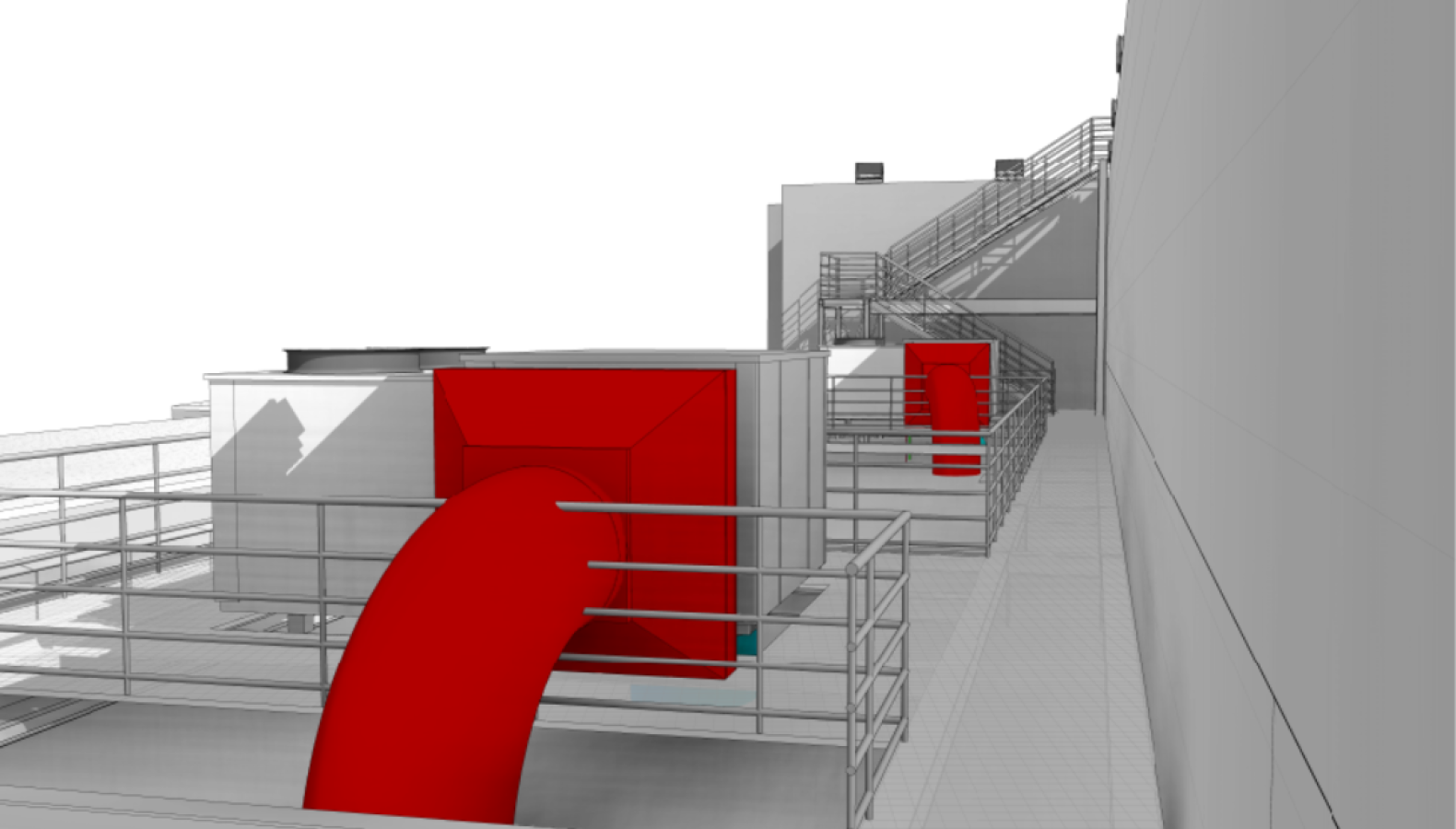

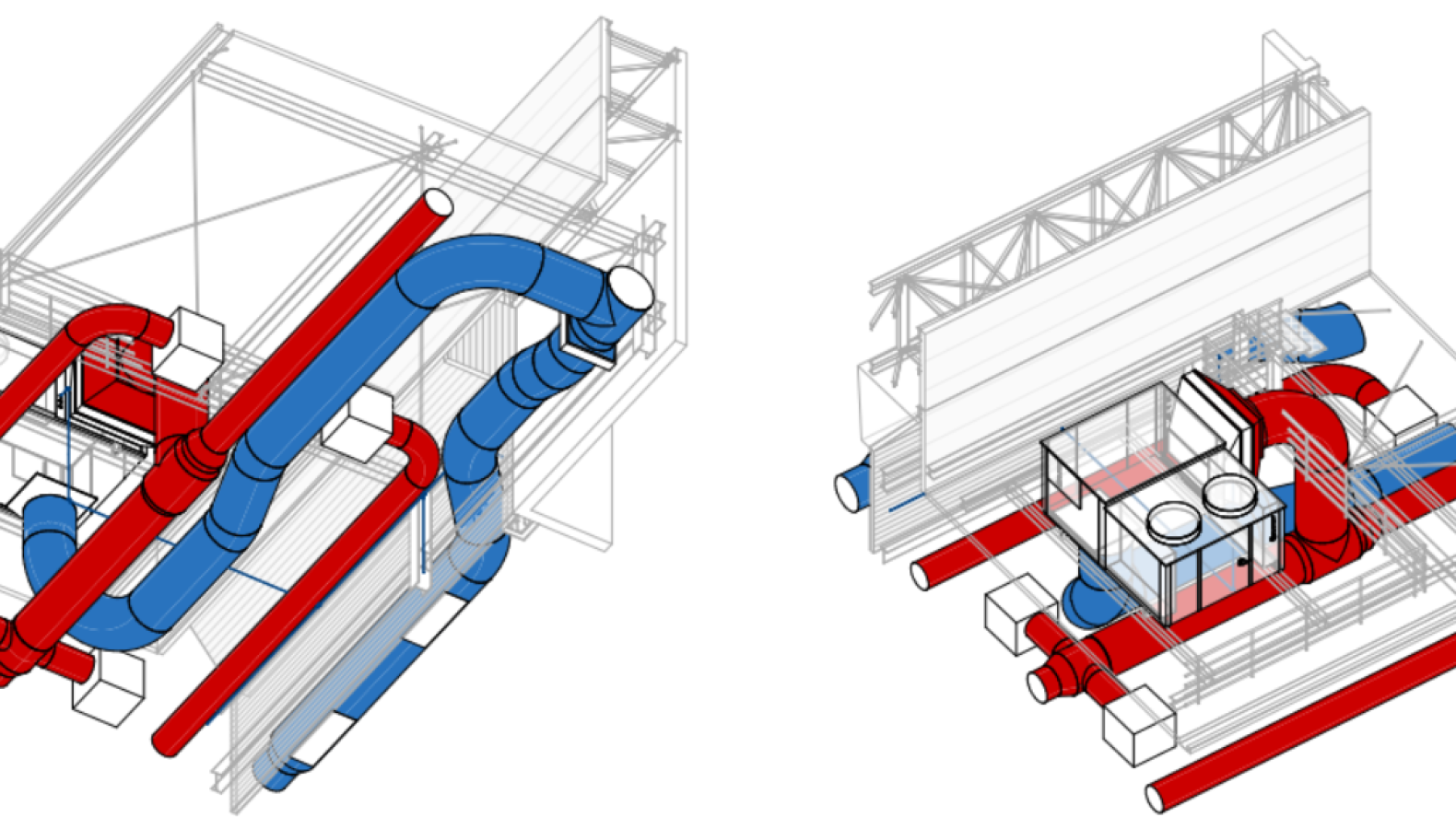

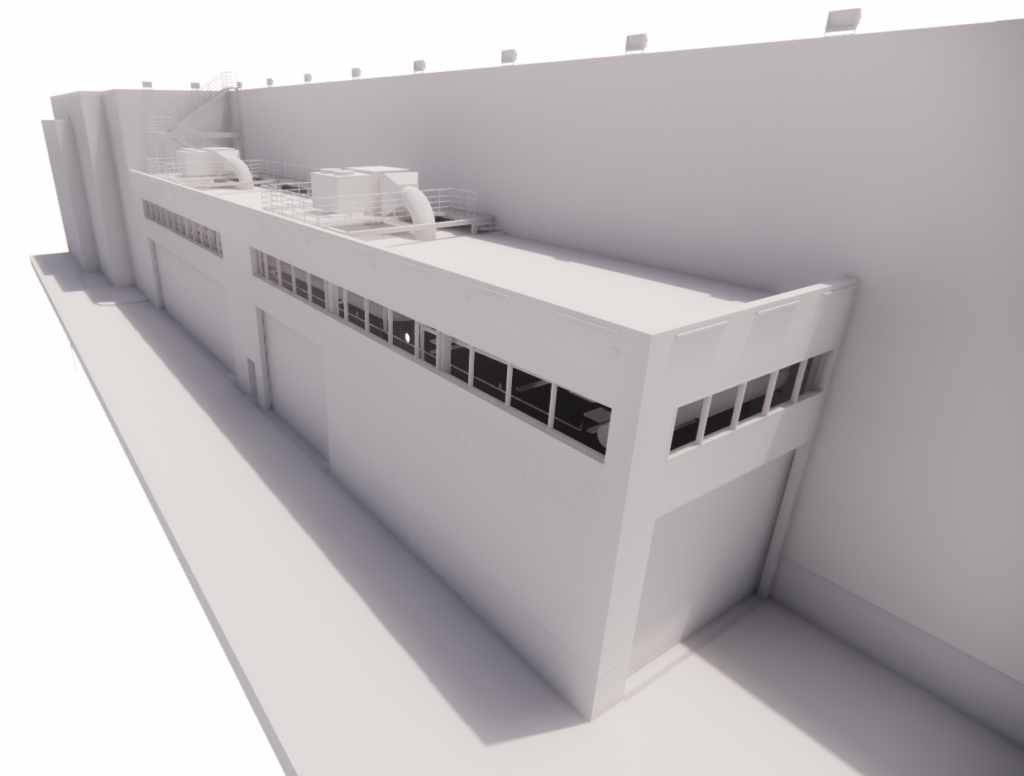

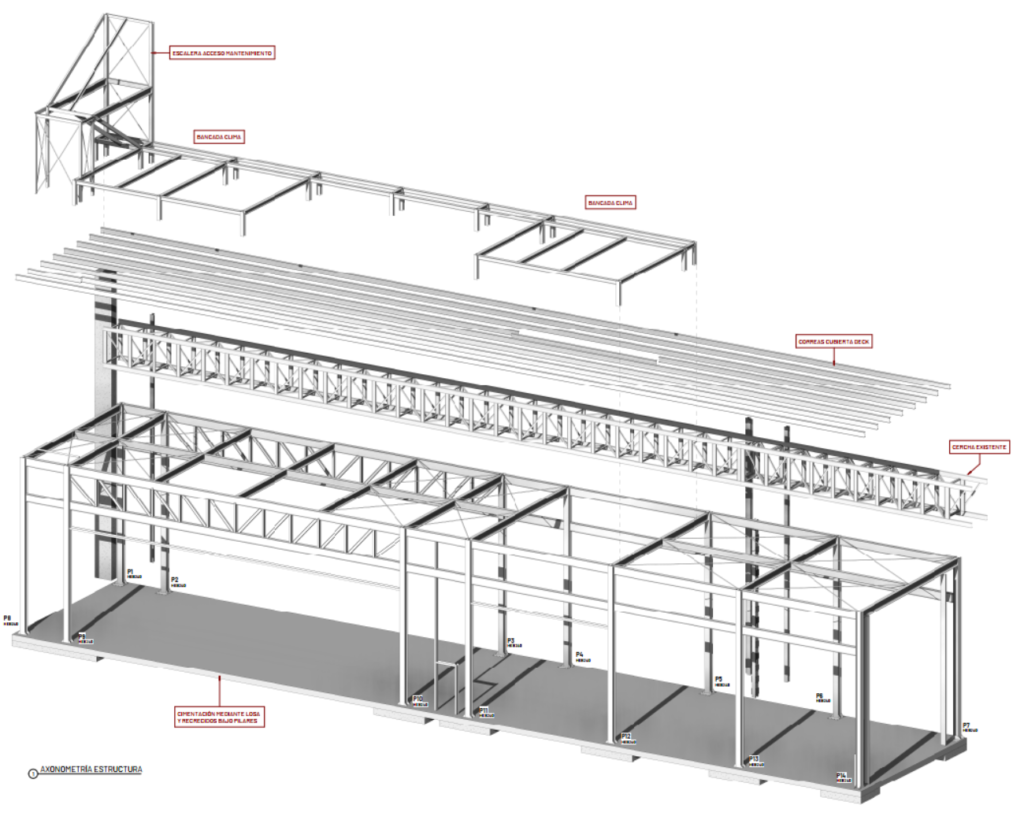

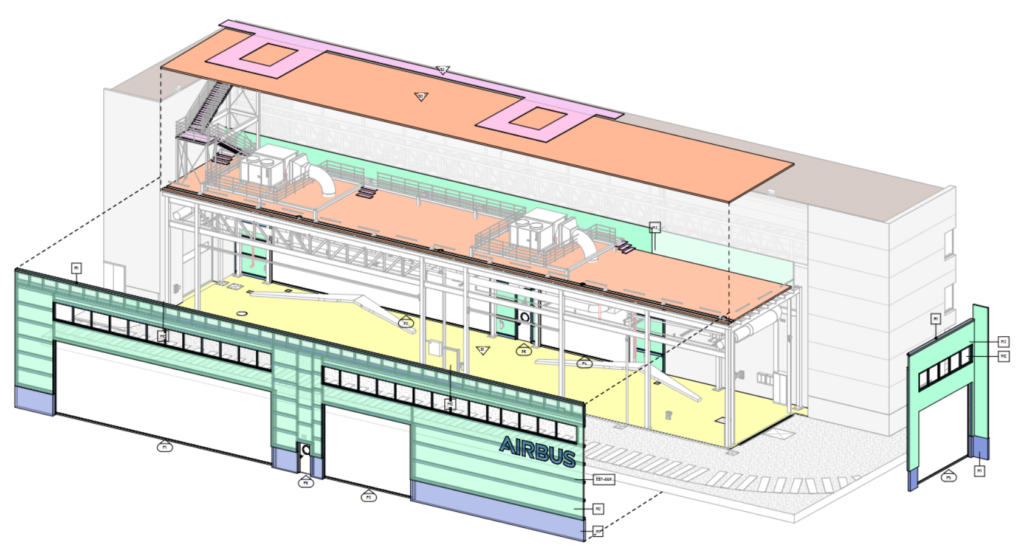

The challenge consisted of introducing large dimension tooling and aeronautical material without compromising the energy efficiency of the facility. The solution proposed by Savener was the development of an additional module designed in the form of an airlock attached to the hall using advanced 3D models.

This intervention not only allows maintaining optimal temperature and humidity conditions inside, crucial for the efficient operation of the production line, but also facilitates the improvement and expansion of circulation flows within the plant. This design not only integrates seamlessly into the existing factory environment, but also extends the infrastructure needed to support and optimise ongoing production.

The implementation of the BIM (Building Information Modelling) methodology, combined with laser scanning and thermal and light simulations, has been fundamental in the design process. These technologies have allowed Savener to increase the accuracy of the virtual model, significantly reducing possible deviations and accurately adjusting the estimated budget. This approach has enabled the development of a high-value project in a reduced timeframe, crucial for Airbus, which faces tight deadlines and cannot afford prolonged slowdowns in its production line.

In addition, the parameterised 3D model generated by Savener offers Airbus the advantage of having a digital twin of the physical model, which opens up future possibilities for integrating it into its maintenance strategies and developing predictive mechanisms. This not only improves the capacity for anticipatory decision-making, but also enhances long-term sustainability and efficiency.

This project stands out for its innovative design, functionality and respectful integration into the factory, demonstrating Savener’s commitment to sustainable solutions and energy efficiency.