- Location: Villalonquejar, Burgos

- Main data: 3.000 kg/h of steam

- Technology: Biomass boiler

- Client: Eiffage

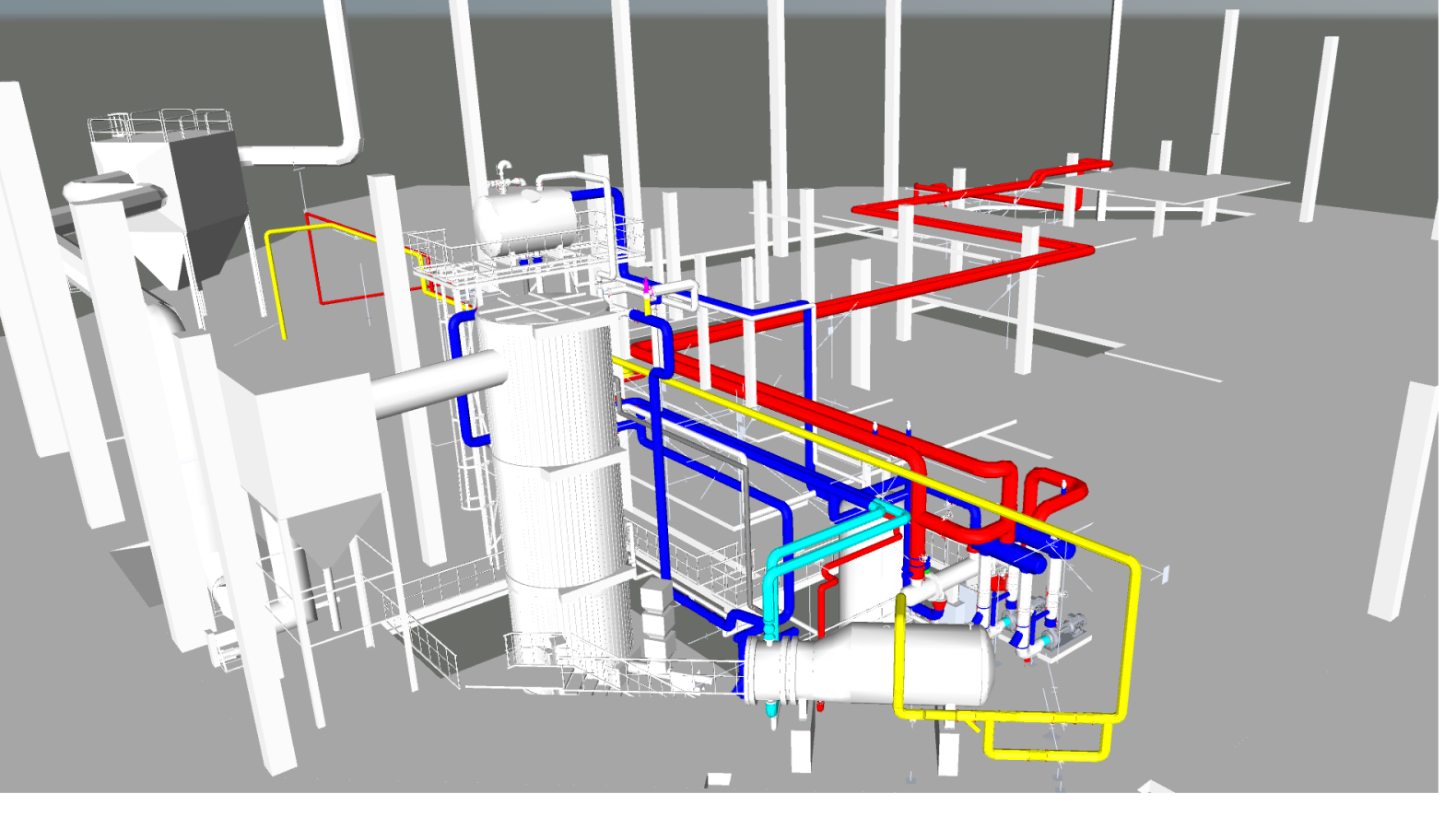

Savener has developed the IFC (Issue for Construction) documentation for the assembly of the piping discipline of a biomass boiler in the industrial estate of Villalonquejar, Burgos.

Eiffage, a benchmark company in the renewable energy sector, has commissioned Savener to generate the detailed engineering documentation necessary for its construction, thus minimising the margin of error in this important phase of the project and with it the costs that could arise.

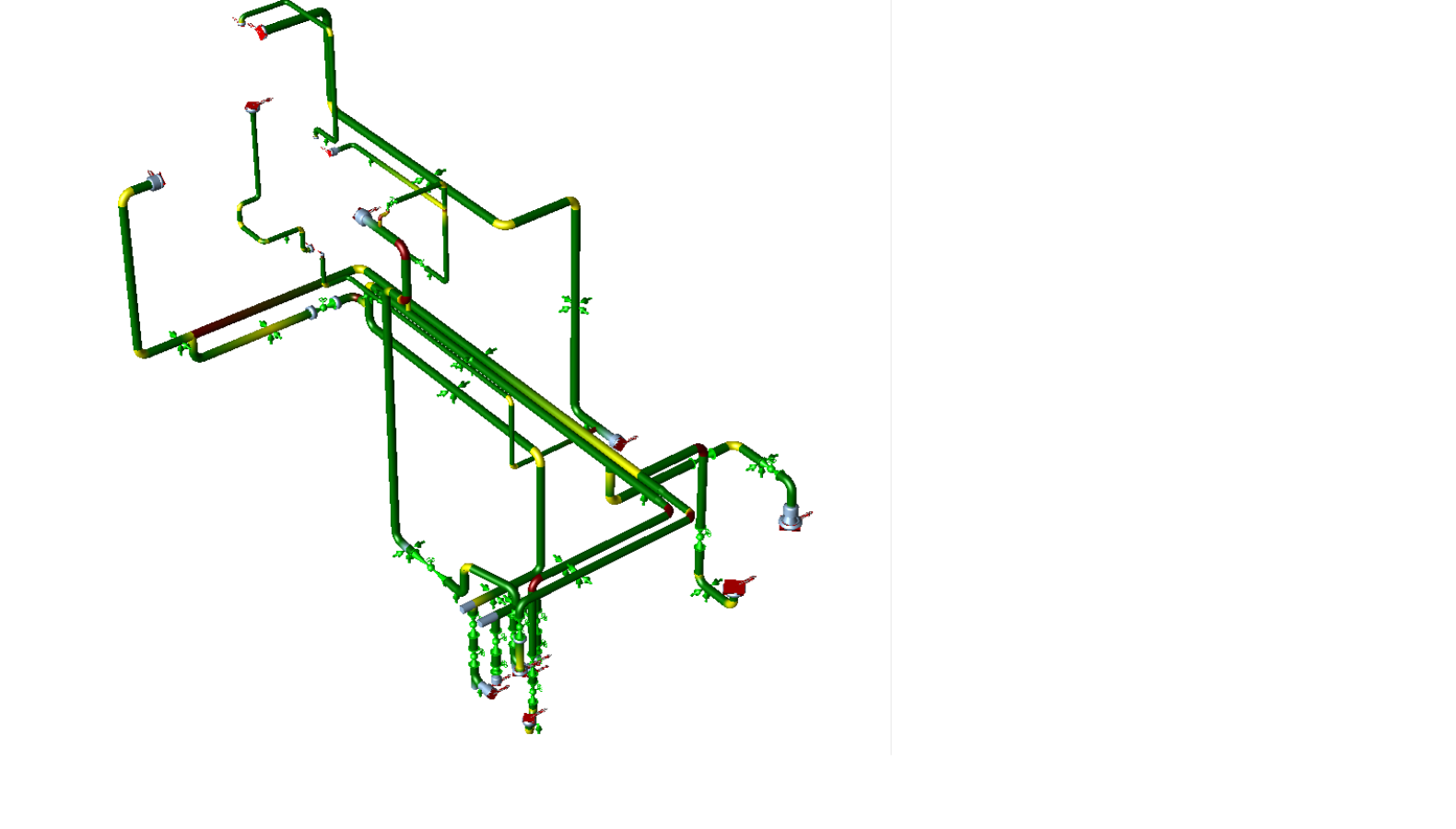

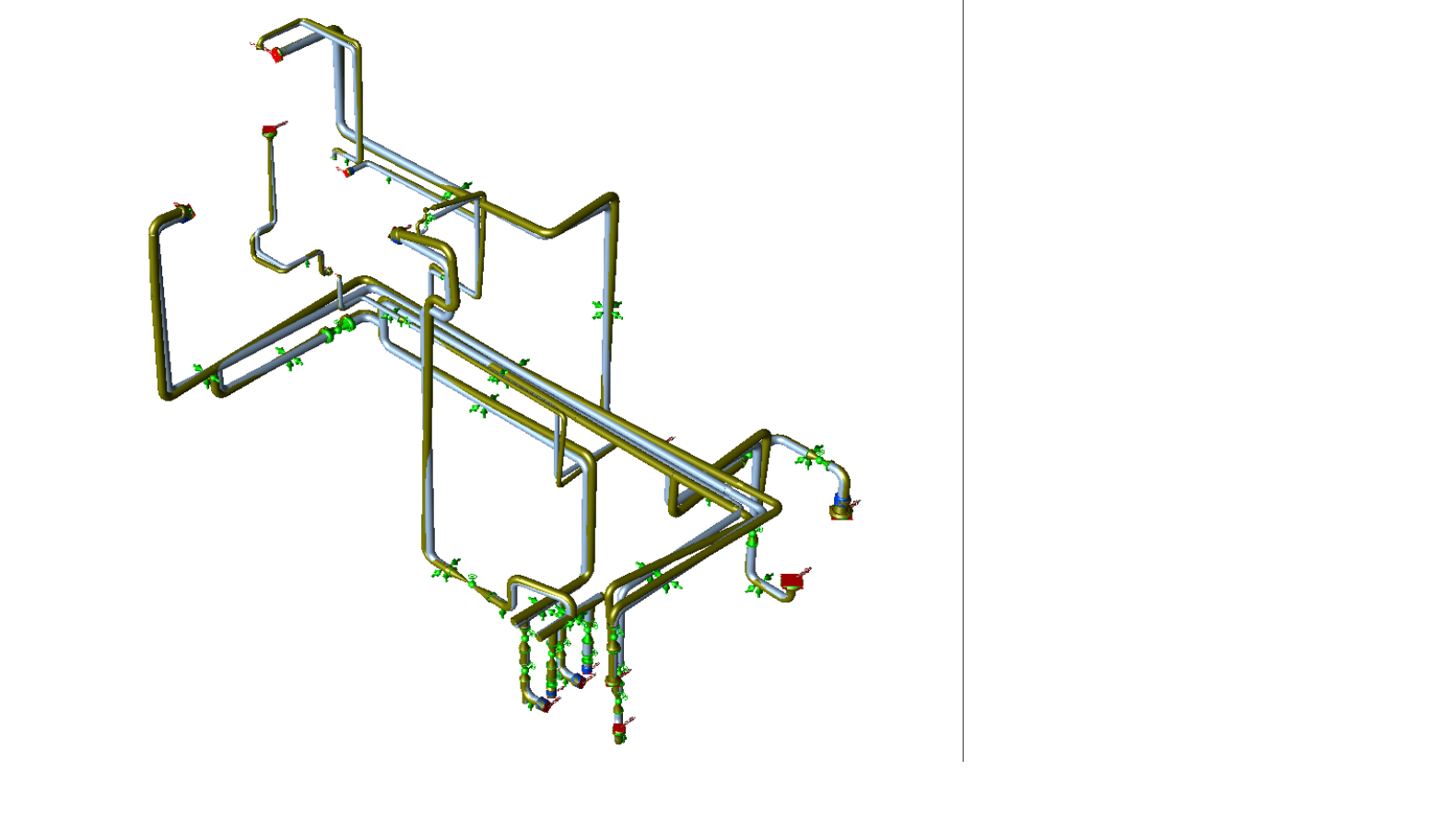

The object in question in this project is a biomass boiler, which produces around 3,000 kg/h of steam, for the L’oreal factory in the Villalonquejar industrial estate and for which the relevant stress calculations, pipe routing, support calculations, flexibility analysis, etc. have been carried out, as well as the hydraulic calculations for the thermal oil pumps, all using the most competitive software on the market.

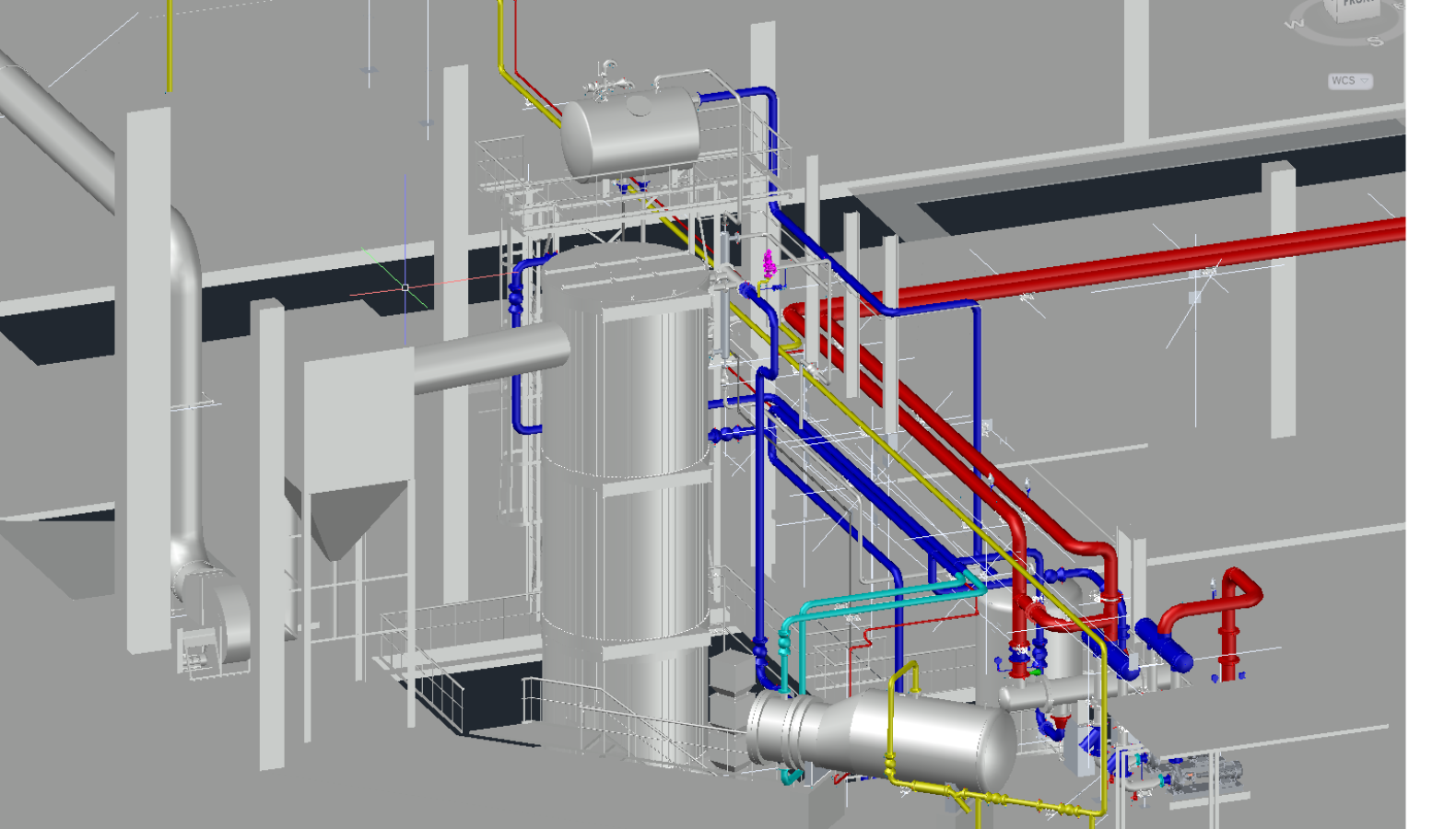

Eiffage, responsible for the construction, has relied on Savener’s extensive experience in specialised calculations of this type to successfully assemble the three parts of the system: oil, steam and superheated water.

The process consists of the boiler heating oil to 350 degrees Celsius. This then passes through a steam generator, which is a heat exchanger in which the superheated water passes through one side and the oil passes through the other, producing the desired steam.

The great challenge of this project has undoubtedly been the limited space available in the plant to house all the equipment and piping. And one of the collateral benefits has been the increase in the amount of steam available on the industrial estate, since, although the main objective was to use it for the L’oreal factory, the surplus can be sold to different nearby companies.

With this project, Savener continues to be committed to highly efficient energy solutions and invests in state-of-the-art calculation system software, for which its professionals are undergoing continuous training.