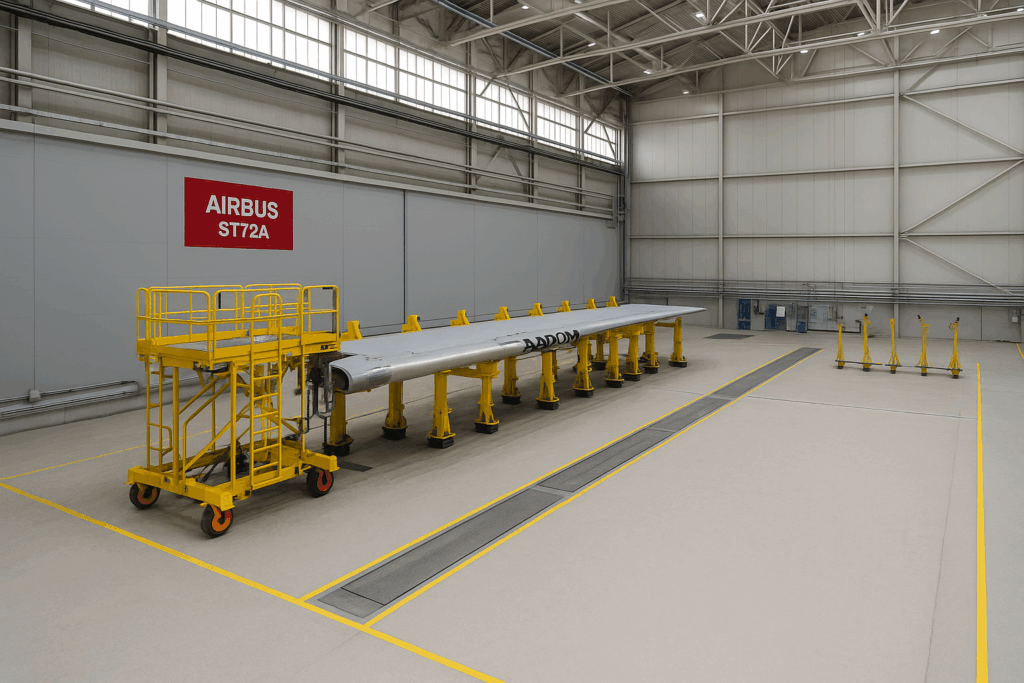

Savener has started a few weeks ago the adaptation works of the ST72A station, in the H1.1 hangar of the AIRBUS factory in San Pablo Sur (Seville), as a continuation of the work developed in the previous technical-economic analysis and its subsequent translation into a complete Basic and Execution Project.

The aim of the project is to completely free up the space previously destined for the integration of the A400M wings, adapting it as an open-plan area for the passage of a specialised transport trolley or as a future storage area, all with a focus on structural safety, functional efficiency and versatility of use.

During this phase, the existing technical installations are being dismantled, the pits and ducts in disuse are being filled in, and a new 25 cm thick reinforced concrete slab is being built, designed to withstand mobile loads of up to 65 tonnes. This structural reinforcement has been designed to ensure the integrity of the pavement against the repeated transit of the trolley carrying the A400M fuselage, distributed on 16 high-capacity wheels. The design has been verified by finite element calculations and laboratory tests, considering a ground reaction modulus of 7500 kN/m³ and reinforcement with B500S steel, thus ensuring that the slab can absorb the stresses generated during trolley manoeuvres without compromising the durability of the infrastructure.

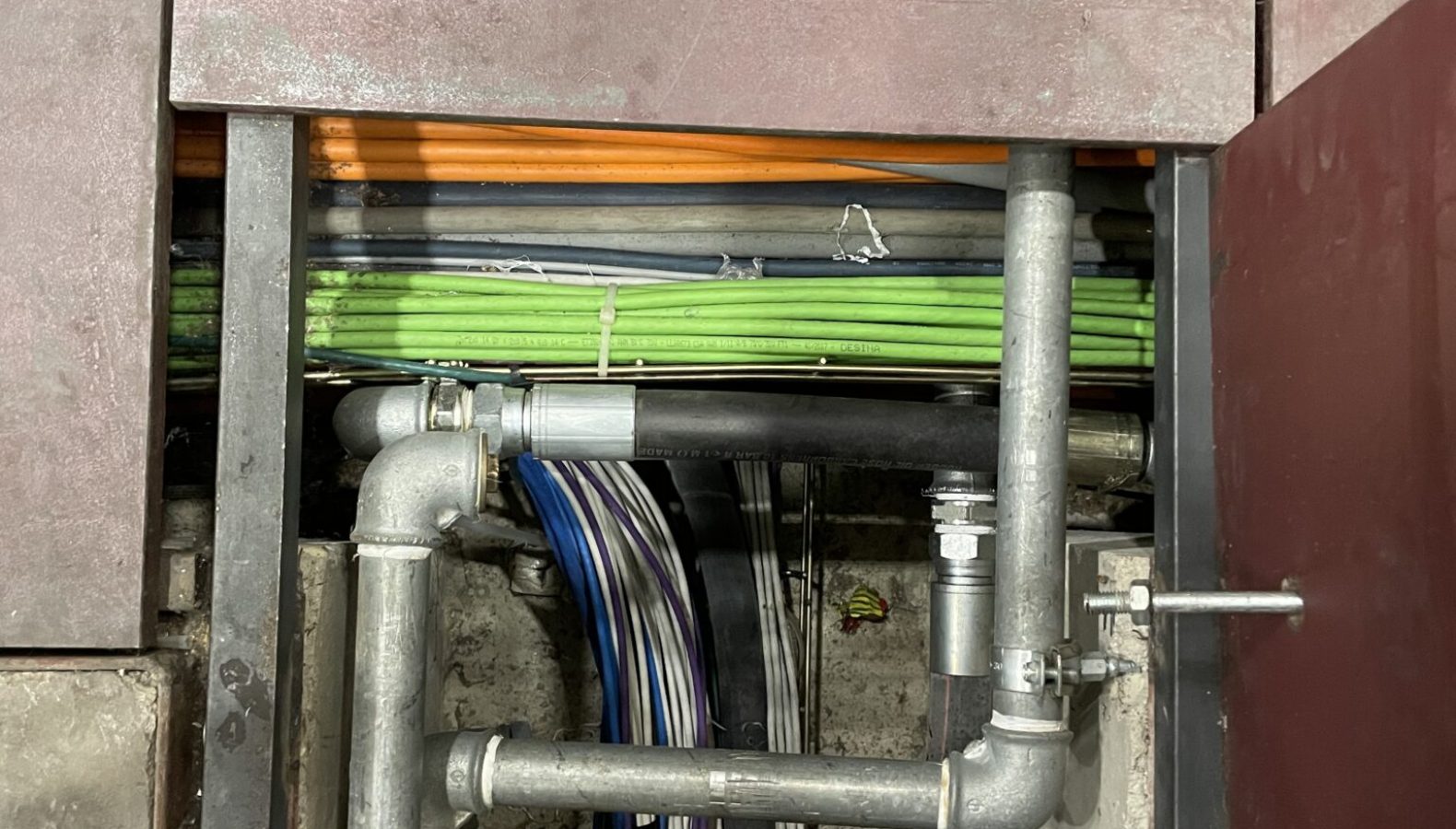

The initial works include the removal of the mobile platforms and systems that served the station’s previous operation. The positioners, the hydraulic platform drive system, the associated electrical installations, as well as the ventilation systems located in the technical pit, including the air treatment unit, the fan, the heat pump and the removable enclosures, are being dismantled. This phase is essential to free up space and prepare the ground for the new functions assigned to the ST72A.

In addition, the piping with potential for future reuse will be selectively retained, and the installation of a new electrical PIT with 250 A connection is envisaged for operations associated with the new production configuration. The design also contemplates optional structural reinforcements in the metallic covers of the piping, capable of increasing their load-bearing capacity by up to 60% or even multiplying it by four, depending on the solution finally implemented.

With this intervention, Savener continues to accompany AIRBUS in the modernisation of its production infrastructures, providing flexible, sustainable solutions adapted to the highest standards of the aerospace sector.