Water is a basic and indispensable commodity and has become even more important in recent years, especially in desert areas such as the Persian Gulf, where there has been a boom in the construction of desalination plants.

Similarly, the firm commitment to more efficient designs has led to an increasingly greater limitation of the energy intensity indicator per m3 of desalinated water (kWh/m3), meaning that the energy vector is becoming increasingly important in the design of these infrastructures.

A key element of high consumption in this type of infrastructure is the HVAC system, which must maintain the electrical and control systems (mainly the Electrical Building) within specific environmental operating conditions. For all these reasons, it is worth carrying out an analysis of the different possible alternatives in order to find the best solution, both technologically, energetically and economically.

Taking the Persian Gulf as an example, the systems traditionally selected for HVAC in the desalination plants located there are air condensation systems, as the installation is simpler to execute and it is “internalised” that they are lower cost (something that may be true in terms of investment, but not in global terms, considering the operating and maintenance costs). Water systems” are practically non-existent, except in those projects where Savener has participated and has been able to demonstrate the energy advantage, durability, simplicity and flexibility of these solutions in extreme climates.

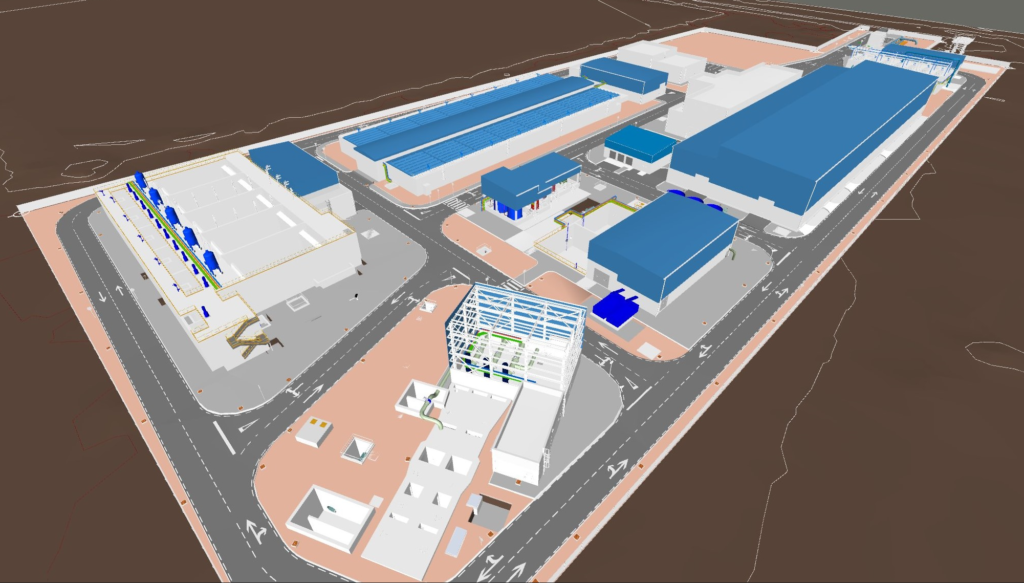

To look at a case study, let’s take a desalination plant in the Middle East Region as an example. If there is one thing that exists in a desalination plant, it is water everywhere, due to the process that is carried out in them and the constant proximity to a huge source of salt water. It is true that these are, in most cases, facilities with a certain level of safety as the final product is intended for human consumption. It is for this reason that the process flow is not to be “interfered” with by any external agent.

The general idea of the Water-Condensed systems is to use the process water from the desalination plant as a sink for the Hot Focus for the cooling cycle. The designed technological solutions can work with any water point of the desalination process, both salt and product water is equally useful, so we can operate with water from any stage of the process. In particular, we can operate with reject water (brine), which minimises the “non-existent” inference risks of this type of solution.

The technological challenges are not few, we must assess transition situations such as plant shutdowns, where there is no process water flow but the electrical systems must be operational and therefore the HVAC, we must resolve the Start Up and commissioning phase, safe and reliable technologies for the exchange and heat transfer between the process and the HVAC system and a long etc. that fortunately the team of specialists at Savener has solved with solvency for some time now.

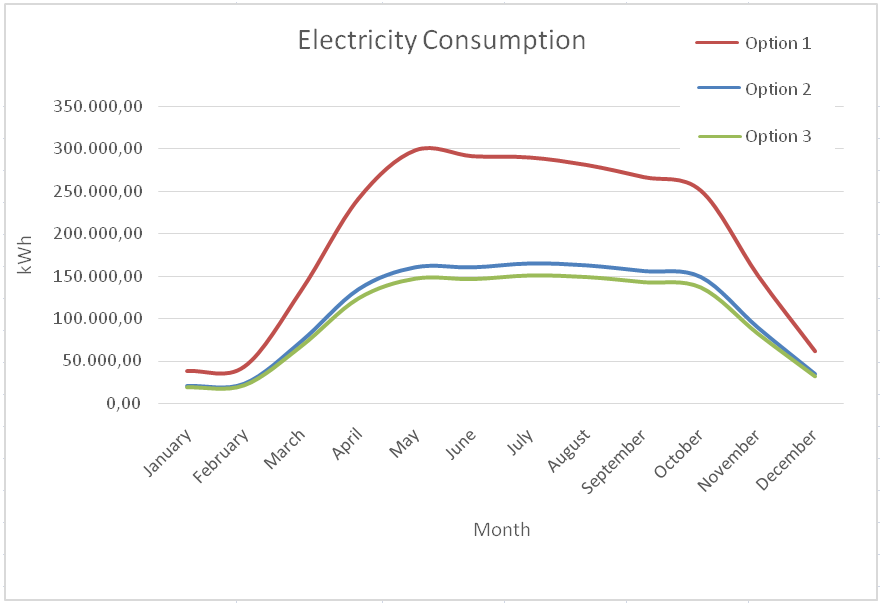

But let’s focus here on the energy advantage of this type of solution in this type of climate and working conditions. To check the significance of this, a comparison has been made taking into account three different types of systems:

1. Air-cooled direct expansion self-contained compact units: Roof-Tops, VRF, stand-alone, etc.

2. Centralised Chiller Plants with process water condensing and air handling terminal units for all spaces to be air-conditioned. The chillers would produce chilled water at 7ºC to meet the requirements of both electrical and occupied rooms.

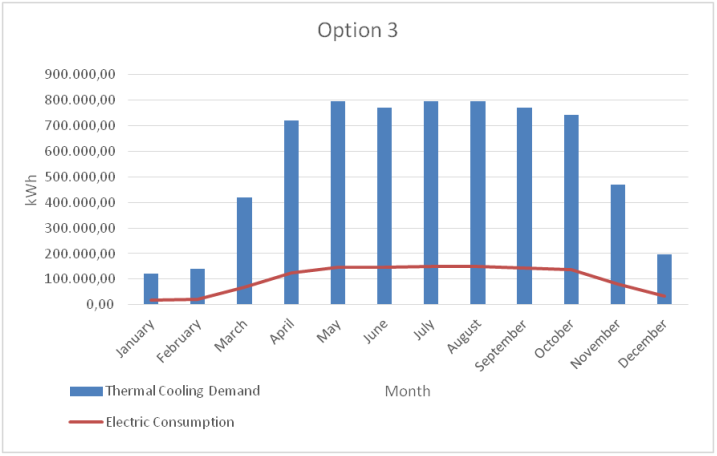

3. Process Water Condensing Chiller Plants with air handling terminal units for Electrical Rooms and another water-cooled Variable Refrigerant Flow (VRF) System for Living Spaces. In this case, the chillers would produce chilled water at 10ºC to take advantage of the higher temperature allowed in the electrical rooms.

Considering the same thermal demand curve for each solution and taking into account the variation of air and process water temperatures throughout the year in this geographical area and its effect on the energy efficiency (EER) of the equipment, the seasonal efficiency ratio (ESEER) can be obtained for each option. We will consider this parameter as a comparison index although the results are equivalent in hourly simulations of the annual behaviour. The ESEER values obtained for each system in the above order are 2.87, 5.04 and 5.52 respectively.

As the results indicate, the system with air condensation is the worst placed and this is due to the fact that this equipment is greatly penalised by the extreme environmental conditions, while water has more stable values and, although it requires a hydraulic circuit and a pumping unit for its operation with its additional consumption, the performance obtained is almost double that of the previous one. It is also evident that the third option obtains slightly better results than the second, as different systems can be used for spaces with different requirements, which allows working with water at a higher temperature in the spaces with the highest demand.

In practice, process water condensing systems in this type of installation and climate require half the electrical power of air-cooled systems. Similarly, the lifetime energy consumption is half that of process water condensing systems.

All this leaving aside other advantages such as space requirements, the possibility of placing the plants in rooms and protecting them from sandstorms that degrade air-cooled systems so much and force constant renovations and repairs, the efficiency in guaranteeing redundancy, etc…

This small approach to this debate for HVAC systems in Desalination Plants in Extreme Climates shows us that the “trends”, the “standard” solutions and the “usual” must always be analysed in detail from a technical and deep point of view, dispelling the doubts and resistance to change of other agents. And especially to break down the separation between the main and auxiliary process systems in order to exploit and enhance the synergies between the two.